1.PlaceboilerintheselecledIocalion(asnearchimneyaspossible.)Your

boilerisshippedassembled.YouneedonlyIoinsfalltheReliefValveand

adrainlineto carryanywalerorsteamIo adrain.

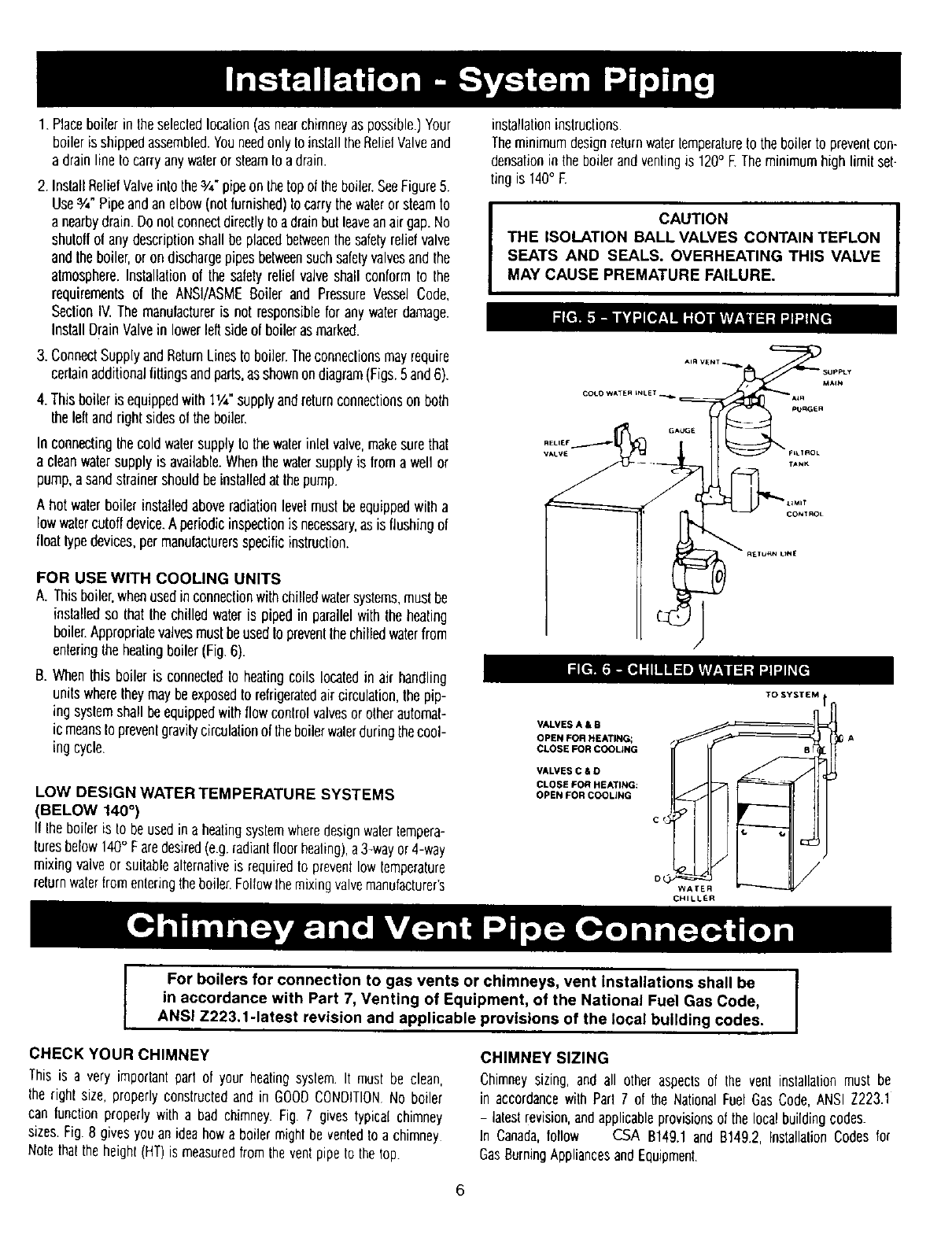

2. InstallRelielValveinto the3/,,-pipeonthetopol Iheboiler.SeeFigure5.

Use¾" Pipeandanelbow(nolfurnished)to carrythewalerorsteamto

anearbydrain.Donotconnectdirectlytoadrainbulleaveanairgap.No

shutollol anydescriptionshallbeplacedbetweenthesafdy rebelvalve

andtheboiler,or ondischargepipesbetweensuchsafetyvalvesandthe

atmosphere.Installationol thesafetyrelielvalveshall conformto the

requirementsof the ANSI/ASMEBoiler and PressureVesselCode,

SeclionIV.Themanulactureris not responsiblefor any waterdamage.

InstallDrainValvein lowerleftsideof boilerasmarked.

3. ConnectSupplyandReturnLinesto boiler.Theconneclionsmayrequire

certainadditionalfiltingsandparts,as shownondiagram(Figs.5and6).

4. Thisboileris equippedwilh 11/4"supplyandreturnconnectionsonboth

theleftandrightsidesol theboiler.

In connectingthecoldwatersupplytothewalerinlelvalve,makesurethat

a cleanwalersupplyis available.Whenthewatersupplyis froma weftor

pump,asandstrainershouldbeinstalledat thepump.

A hotwalerboiler installedaboveradiationlevelmustbeequippedwilh a

lowwatercutoffdevice.A periodicinspectionis necessary,as is flushingof

floattypedevices,permanufacturersspecificinstruction.

FOR USE WITH COOUNG UNITS

A. Thisboiler,whenusedinconnectionwithchilledwatersystems,mustbe

installedso that thechilled wateris pipedin parallelwiththeheating

boiler.Appropriatevalvesmustbeused1oprevenlthechilledwaterfrom

enteringtheheatingboiler(Fig.6).

B. Whenthisboiler is connectedto heatingcoils locatedin air handling

unitswheretheymaybeexposedto refrigeratedaircirculation,thepip-

ing syslemshallbeequippedwithflowcontrolvalvesorotherautomaf-

ic meansto prevenlgravgycirculationof theboilerwalerduringthecool-

ing cycle.

LOW DESIGN WATER TEMPERATURE SYSTEMS

(BELOW 140°)

If Iheboileris to beusedin aheatingsysfemwheredesignwaterlempera-

luresbelow140° Faredesired(e.g.radianlfloorhealing),a3-wayor4-way

mixingvalveor suitablealternativeis requiredto preventlowfemperature

returnwaterfromenleringtheboiler.FollowIhemixingvalvemanufacturer's

installationinstructions.

TheminimumdesignreturnwaterLemperatureIo theboilerto prevenlcon-

densationin theboilerandventingis 120° E Theminimumhigh limil set-

ting is 140° F.

I CAUTION

THE ISOLATION BALL VALVES CONTAIN TEFLON

SEATS AND SEALS. OVERHEATING THIS VALVE

MAY CAUSE PREMATURE FAILURE.

COt.o WATE_ LNLET.

VALVES A & B

OPEN FOR HEATING;

CLOSE FOR COOLING

VALVES C &O

CLOSE FOR HEATING:

OPEN FOR COOLING

TO SYSTEM

c d

WAFER

CHILLER

For boilers for connection to gas vents or chimneys, vent Installations shall be

in accordance with Part 7, Venting of Equipment, of the National Fue| Gas Code,

ANSI Z223.1-1atest revision and applicable provisions of the local building codes.

CHIMNEY SIZING

CHECK YOUR CHIMNEY

Thisis a very imporfantpart of your heatingsystem It mustbe clean,

theright size, properlyconstructedandin GOODCONDITIONNo boiler

can lunctionproperlywith a bad chimney.Fig. 7 givestypical chimney

sizes.Fig.8 givesyouanideahowa boilermightbe ventedto achimney

Nofetha_theheight(HT)is measuredfromtheventpipeto the lop.

Chimneysizing, and all other aspectsof the vent installationmust be

in accordancewith Part7 of the NationalFuelGasCode,ANSIZ223.1

- laleslrevision,andapplicableprovisionsof the localbuildingcodes.

In Canada,follow CSA B149.1and B149.2,InstallabonCodesfor

GasBurningAppliancesandEquipment.

6