15

The temperature-pressure relief valve must be manually operated

at least once a year. Caution should be taken to ensure that

(1) no one is in front of or around the outlet of the temperature-

pressure relief valve discharge line, and (2) the water manually

discharged will not cause any bodily injury or property damage

because the water may be extremely hot.

If after manually operating the valve, it fails to completely reset

and continues to release water, immediately close the cold water

inlet to the water heater, follow the draining instructions, and

replace the temperature-pressure relief valve with a new one.

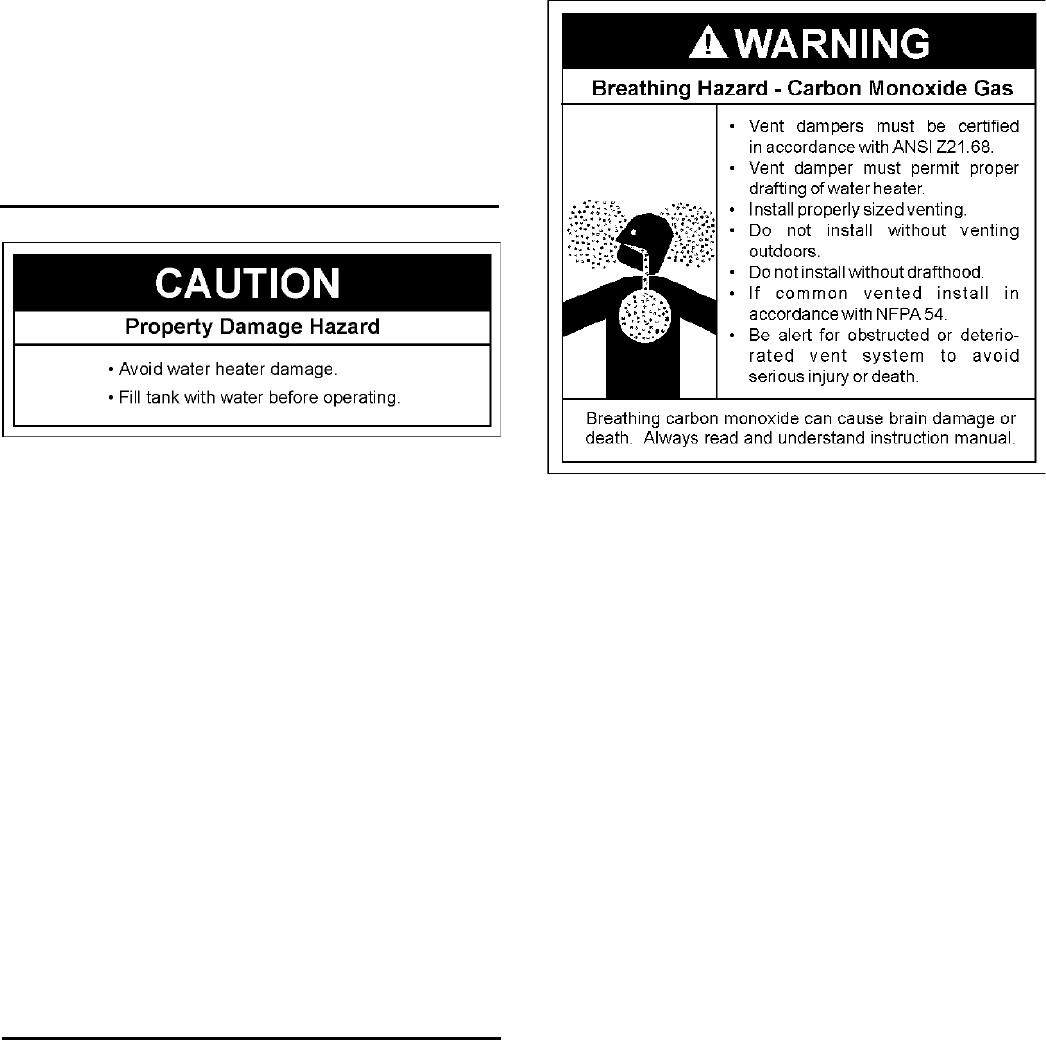

Filling the Water Heater

Never use this water heater unless it is completely full of water.

To prevent damage to the tank, the tank must be fi lled with water.

Water must fl ow from the hot water faucet before turning “ON”

gas to the water heater.

To fi ll the water heater with water:

• Close the water heater drain valve by inserting a fl at head

screwdriver in the slot on the stem and turn to the right

(clockwise). The drain valve is on the lower front of the water

heater.

• Open the cold water supply valve to the water heater.

NOTE: The cold water supply valve must be left open

when the water heater is in use.

• To insure complete fi lling of the tank, allow air to exit by

opening the nearest hot water faucet. Allow water to run until

a constant fl ow is obtained. This will let air out of the water

heater and the piping.

• Check all water piping and connections for leaks. Repair as

needed.

Venting

VENT DAMPERS - Any vent damper, whether it is operated

thermally or otherwise must be removed if its use inhibits proper

drafting of the water heater.

Thermally Operated Vent Dampers: Gas-fi red water heaters

having thermal effi ciency in excess of 80% may produce a

relatively low fl ue gas temperature. Such temperatures may

not be high enough to properly open thermally operated vent

dampers. This would cause spillage of the fl ue gases and may

cause carbon monoxide poisoning.

Vent dampers must bear evidence of certifi cation as complying

with the current edition of the American National Standard

ANSI Z21.68 (ANSI Z21.66 & 67, respectively, cover electrically

and mechanically actuated vent dampers). Before installation

of any vent damper, consult your local Sears Service Center or

the local gas supplier for further information.

To insure proper venting of this gas-fi red water heater, the correct

vent pipe diameter must be utilized. Any additions or deletions

of other gas appliances on a common vent with this water

heater may adversely affect the operation of the water heater.

Consult your gas supplier if any such changes are planned.

For replacement heater installations where pre-existing venting

is used, the venting must be inspected for obstructions and if

deterioration is present, it must be replaced.

For proper venting in certain installations, a larger diameter vent

pipe may be necessary. Consult your local Sears Service Center

or gas supplier to aid you in determining the proper venting for

your water heater from the vent tables in the current edition of

the National Fuel Gas Code ANSI Z223.1/NFPA 54.

Periodically check the venting system for signs of obstruction or

deterioration and replace if needed.

The combustion and ventilation air flow must not be

obstructed.

The water heater with draft hood installed must be connected

to a chimney or listed vent pipe system, which terminates to the

outdoors. Never operate the water heater unless it is vented

to the outdoors and has adequate air supply to avoid risks of

improper operation, explosion or asphyxiation.

• For proper draft hood attachment, the draft hood legs may

be angled slightly inward.

• Place the draft hood legs in the receiving holes on the top

of the water heater. The legs will snap in the holes to give a

tight fi t. Secure the legs to top with sheet metal screws. See

Figure 17.

• Place the vent pipe over the draft hood. With the vent pipe

in position, drill a small hole through both the vent pipe and

draft hood. Secure them together with a sheet metal screw.

Obstructed or deteriorated vent systems may present serious

health risk or asphyxiation.