562156-UIM-A-0610

14 Johnson Controls Unitary Products

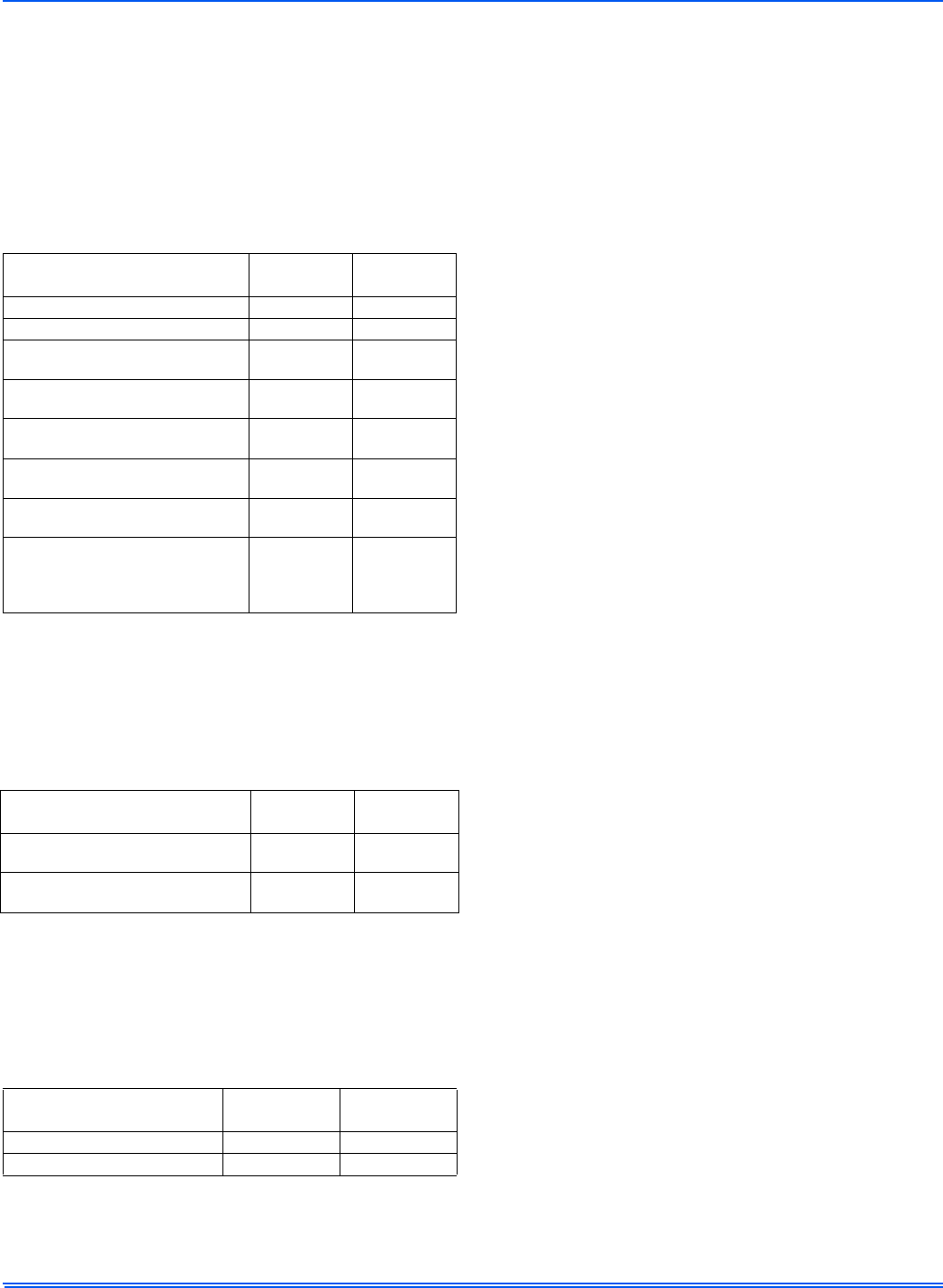

FAULT CODE DISPLAY

The control will display any fault code that is currently active using the

LED’s. The control will display the fault code, pause two seconds, and

display the fault again. The control will continue the fault code display

until the condition that caused the fault code no longer exists. If multiple

fault codes are present at the same time, the control will display only

the most recent fault.

Table 6 describes the operational faults that the control can detect. The

control displays these types of errors by flashing the LED1 (Red) and/or

LED2 (Green).

SENSOR OR SWITCH FAULT CODES

Table 7 describes the faults that the control can detect when a problem

is present with a sensor or switch. The control displays this type of error

by energizing LED1 (Red) constantly and flashing LED2 (Green).

These faults typically occur when an AC unit has been operating and a

problem occurs with a sensor or its wiring. These faults could also occur

during installation as the AC unit is configured.

WIRING RELATED FAULT CODES

Table 8 describes the faults that the control can detect when a problem

is present with the system wiring or jumper configurations. The control

displays this type of error by flashing LED1 (Red) and energizing LED2

(Green) constantly. These faults typically occur when the AC unit is first

installed or when a system component such as the room thermostat or

indoor unit is replaced or rewired.

LOCKOUT MODES

Soft Lockout

The control will cause a soft lockout during the following conditions.

Detailed descriptions of the conditions required for the control to enter

the soft lockout mode are contained in other sections of this document.

1. High-pressure switch

a. Two openings within six hours

2. Low-pressure switch

a. One opening of the switch for more than five seconds except

under certain conditions.

During the soft lockout mode, the control will do the following.

1. De-energize the compressor contactor outputs (M, M1, & M2).

2. Energize the LED’s with the appropriate flash codes as described

elsewhere in this document.

3. In communication applications the fault code will be stored in the

thermostat. (This feature is not available for non communicating

applications).

The control will reset the soft lockout condition when any of the follow-

ing occur following removal of the fault condition.

1. Power is cycled to the R or Y1 inputs of the control. This will cause

the soft lockout condition to be reset when the thermostat is satisfied

or when the thermostat is set to SYSTEM OFF and back to HEAT or

COOL mode.

2. The TEST terminals are shorted for more than two seconds.

When the soft lockout condition is reset, the control will stop displaying

the fault code and will respond to thermostat inputs normally.

Hard Lockout

If four soft lockouts occur within a twelve-hour period, the control will

cause a hard lockout condition. These soft lockouts can be caused by

the same or different conditions. The control will function in the same

way during soft and hard lockout conditions. The difference is in the

requirements for resetting the lockout condition. The control will reset

the hard lockout condition when any of the following occur following

removal of the fault condition.

1. Power is removed from the R input of the control.

2. The TEST terminals are shorted for more than two seconds.

A hard lockout condition will not be reset when the thermostat is satis-

fied or when the thermostat is set to SYSTEM OFF and back to HEAT

or COOL mode. Power (24 VAC) to the control must be removed and

reapplied.

When the hard lockout condition is reset, the control will de-energize

the LED’s and respond to inputs/communication normally.

Wiring or Setting Related Lockouts

The control will not operate the compressor when the following faults

occur. These faults can be reset using the same methods used to reset

a soft lockout. However, two occurrences of these faults will not cause a

hard lockout condition.

1. Presence of Y2 thermostat signal without Y1.

If a compressor wiring error is detected, the control will not operate the

compressor. Once the compressor wiring error has been detected,

power (24 VAC) must be cycled to the control for the control to sense

the wiring change and clear the lockout condition.

TABLE 6:

Operational Fault Codes

Description

LED1 Flash

Code (Red)

LED2 Flash

Code (Green)

Control Failure ON OFF

Operational Faults

High-pressure switch fault (not in

lockout yet)

1OFF

System in high-pressure switch

lockout

2OFF

System in low-pressure switch

lockout

4OFF

Low Voltage (<19.2VAC) preventing

further relay outputs

5OFF

Low Voltage (<16 VAC) stopped

current relay outputs

6OFF

High-pressure switch fault (with no

communication for compressor

operation and where Y1 and Y2

are not energized)

9ON

TABLE 7:

Sensor or Switch Fault Codes

Description

LED1 Flash

Code (Red)

LED2 Flash

Code (Green)

Outdoor ambient temperature

sensor failure (short)

ON 1

Outdoor ambient temperature

sensor failure (open)

ON 2

TABLE 8:

Wiring Related Fault Codes

Description

LED1 Flash

Code (Red)

LED2 Flash

Code (Green)

Compressor contactor miswire 1 ON

Y2 present without Y1 2 ON