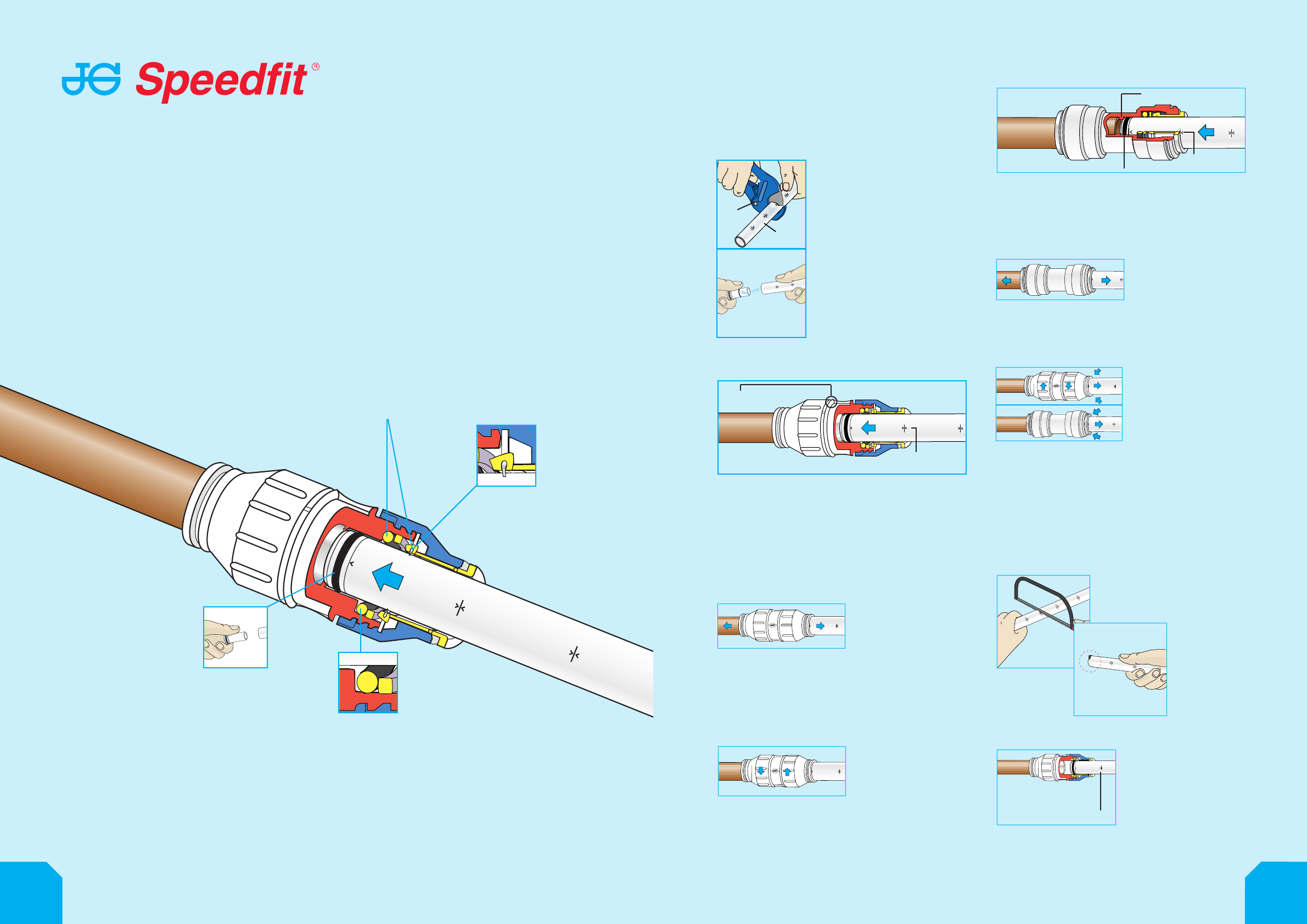

HOW SPEEDFIT WORKS

Grips before it seals

Main ʻOʼ Ring Seal

Stainless steel teeth

grip the pipe

Pipe insert gives

secondary seal

Speedfit Fittings have a unique grip then seal construction made up of a collet with stainless

steel teeth to grip the pipe and an ‘O’ ring to provide a permanent leak proof seal.

Use of the Superseal Pipe Insert ensures a double ‘O’ ring seal.

An ‘O’ ring at the head of the insert and the shape of the stem, provide a secondary seal against

the bore of the fitting. A combination of this and the main ‘O’ ring ensure a good connection.

The stem of the insert gives greater rigidity of the length of pipe within the fitting, reducing the

chance of leaks if a side load is applied.

The head of the insert has been designed for ease of insertion.

The additional benefit of Twist and Lock Fittings is that a twist of a screwcap locks the pipe in

position and gives increased compression on the ‘O’ ring for even greater security.

MAKING A GOOD CONNECTION

Pipe Cutter

JG TS

Speedfit

Barrier Pipe

Ensure the pipe is free of score

marks. Cut the pipe square.

When using Speedfit Barrier Pipe

cut along an insertion mark. We

recommend the use of JG Pipe

Cutters.

To prevent damage to the ‘O’ ring

remove all burrs and sharp edges.

When connecting Speedfit Pipe

use a Superseal Pipe Insert. A

twisting motion will aid insertion.

The insert should only be used

with Speedfit Pipe.

Fittings and pipe should be kept clean bagged and undamaged

before use.

NEW TWIST AND LOCK FITTINGS

The fitting should be in the ‘unlocked’ position, this is

shown with a small gap between the screwcap and the

body flange.

Push the pipe fully into the fitting, up to the pipe stop. If

the Speedfit Pipe has been cut correctly the insertion

mark on the pipe will be level with the collet head. The ‘O’

ring on the Superseal Pipe Insert provides a secondary

seal against the bore of the fitting. A good connection

has been made.

Gap between Cap

and Flange

Pipe mark indicates

full insertion

Twist the screwcap until it

touches the body flange.

This increases the ‘O’ ring

seal around the pipe and

locks the pipe into position.

If you are not using collet

clips, ensure that the

screwcaps are in the

locked position.

Pull to check it is secure. It is good practice to test the system

prior to leaving the site or before use. Our recommended

test procedure is shown in our Technical Checklist.

ADDED BENEFIT TWIST AND LOCK

STANDARD SPEEDFIT FITTINGS

Standard Speedfit connections are made in the same way

as Twist and Lock.

Push Pipe up to Pipe Stop. If the Speedfit Pipe has been

cut correctly the insertion mark on the pipe will be level

with the collet head.

Push pipe up to stop

Secondary Seal

Pipe mark indicates

full insertion.

Pull to check connection

is secure and test the

system. Our recommended

test procedure is shown

in our Technical Checklist

on page 29.

TO DISCONNECT

Ensure that the system

is depressurised.

The screwcap on Twist

and Lock Fittings will

need to be turned back

to the unlocked position.

WHAT NOT TO DO

Fitting may be gripped but not

sealed if pipe is not fully inserted.

Don’t use hacksaws to cut the

pipe or leave burrs on the end of

the pipe.

Do not insert fingers into the fitting as the stainless steel

teeth may cause injury.

Remember to pressure test the completed installation

according to the recommendations in our Technical Checklist.

✗

✗

Don’t use

damaged or

scored pipe.

✗

PREPARE THE PIPE

05

06

Push the collet square against the face of the fitting by

using fingers or with the help of our collet release tool.

With the collet held in position the pipe can be removed.

The fitting can be used again without the need for

replacement parts.

Don’t forget to push the

pipe fully into the fitting,

past both the collet (gripper)

and the ‘O’ ring.