Page 2 of 8 TP1044S5XXXXXXXX (en)

OPERATING INSTRUCTIONS / INITIAL SET-UP PROCEDURE

WARNING

Stand clear when raising or lowering the lift.

Read the warnings on page 3 of RM552S-XX Two Post Lift / Ram

Operator’s Manual.

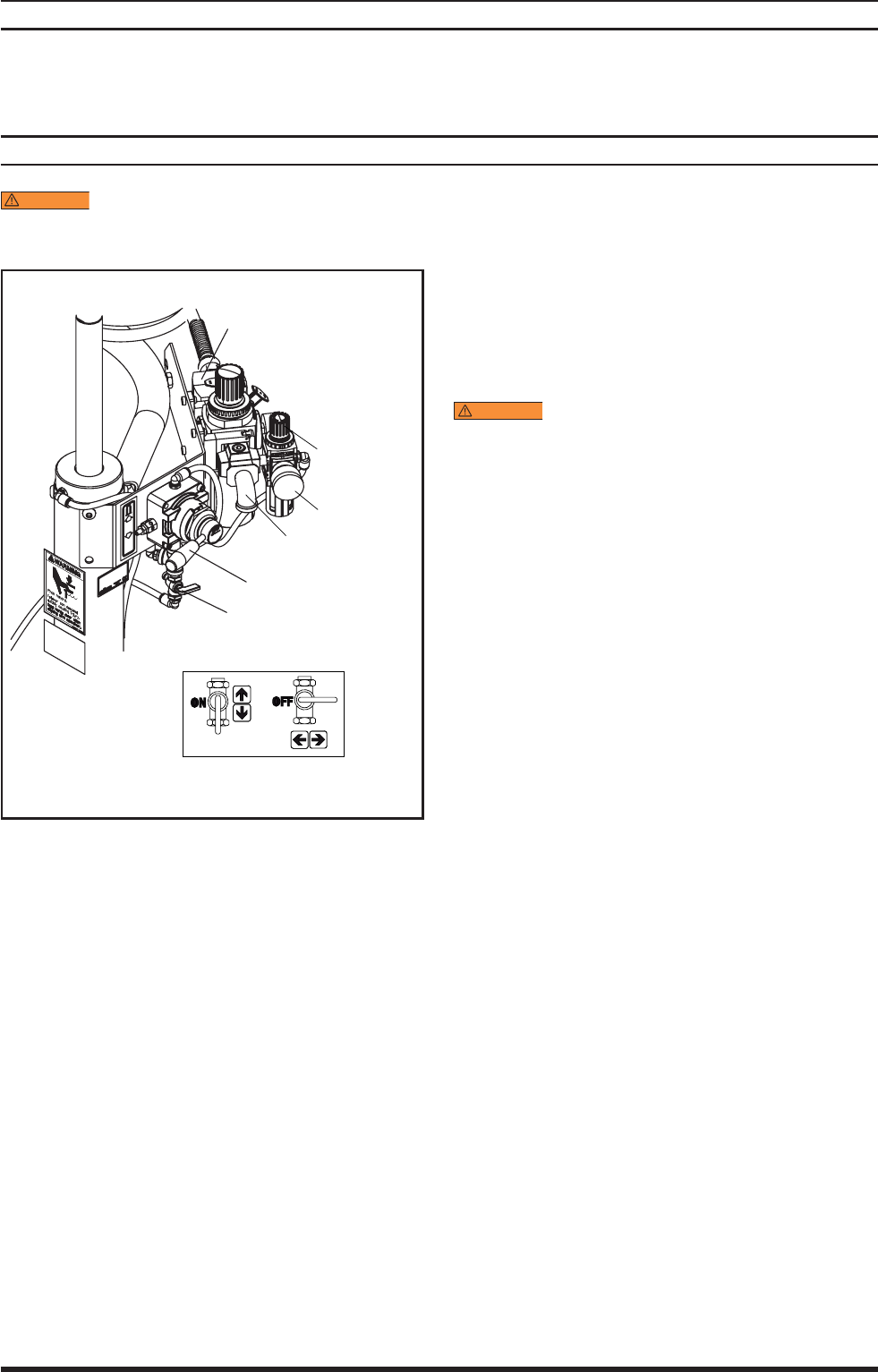

AIR CONTROLS

Control Lever

Follower Plate

Air Supply Valve

Ram air iter /

regulator

Pump air supply valve

Gauge

Air Inlet

(1/4 - 18 N.P.T.)

Figure 2

TO RAISE THE LIFT, (the rst time):

Take note of the pump / drum clearance above. Be certain the

lift / ram is clear of any objects above. Also, refer to “Operating

and Safety Precautions” found on page 3 of RM552S-XX Two

Post Lift / Ram Operator’s Manual.

Connect the air supply (100 p.s.i. max.) to the air inlet. Adjust

the air pressure on the lift / ram pressure regulator (turn the

knob clockwise) to 30 - 40 p.s.i. (2.1 - 2.8 bar).

Shift the control valve lever to the “up” position.

Raise the lift / ram high enough to clear the height of the drum.

Stop the lift upward travel by moving the control valve lever to

the “neutral” (center) position.

Once the lift / ram assembly and pump are in the “up” position,

1.

2.

3.

4.

5

.

INSTALLATION

The TP1044S5XXXXXXXX Extrusion System comes completely

assembled. Remove the unit from the crate and place on a level

surface. Install the material hose and dispensing device as required.

When the following instructions are observed, heavy paste

materials can be pumped directly from their original drum

without air inclusion or excessive waste. The follower plate creates

an air tight seal as well as clean-wiping action in its progressive

downward movement into the drum.

OPERATING INSTRUCTIONS

place and center an opened drum of material on the lift / ram

base and securely against the barrel guides, adjusting if neces-

sary.

Lubricate the lower follower wiper plate seal with grease. NOTE:

Make certain the grease is compatible with the material being

dispensed. This ensures a smooth t into the drum, as well as

prevents curing type compounds from bonding to the seal.

Check the vent plug on the follower plate to be sure it easily

threads in and out. It is recommended to lubricate the threads

of the plug to help prevent possible set-up of the compound at

this point.

TO LOWER LIFT:

WARNING

PINCH HAZARD. Follower can descend quickly,

causing injury. Keep hands clear when aligning with con-

tainer. Read the warnings on page 3 of RM552S-XX Two Post

Lift / Ram Operator’s Manual.

NOTE: Be certain the follower plate vent plug has been removed

so that the air trapped between the follower and the material is al-

lowed to escape from this vent.

NOTE: The lift / ram may hesitate momentarily before starting

downward. The air pressure inside the post air chamber must de-

crease before it will begin to descend.

Shift the control valve lever to the “down” position and proceed

to lower the pump.

Replace the vent plug once the material begins to ooze from

the vent opening.

The unit is now ready for operation. Adjust the air pressure

on the pump lter / regulator (turn the pump regulator knob

clockwise) until the pump begins to cycle.

Trigger the gun to prime the pump with material.

TO RAISE LIFT, (normal operation):

Adjust the follower plate air valve pressure up to approximately

8 p.s.i.g. (0.55 bar). DO NOT OVER PRESSURIZE THE DRUM to

avoid damage. NOTE: Air from this valve will only pass when

the control lever is in the “up” position.

Shift the control valve lever to the “up” position.

Raise the lift / ram high enough to clear the height of the drum.

Stop the lift upward travel by moving the control valve lever to

the “neutral” (center) position.

TO CHANGE THE DRUM:

NOTE: The control valve lever must be in the “neutral” position.

Remove the old drum.

Place and center a new drum into position.

6.

7.

1.

2.

3.

4.

1.

2.

3.

1.

2.