PD30X-XXX-XXX-C (en) Page 5 of 8

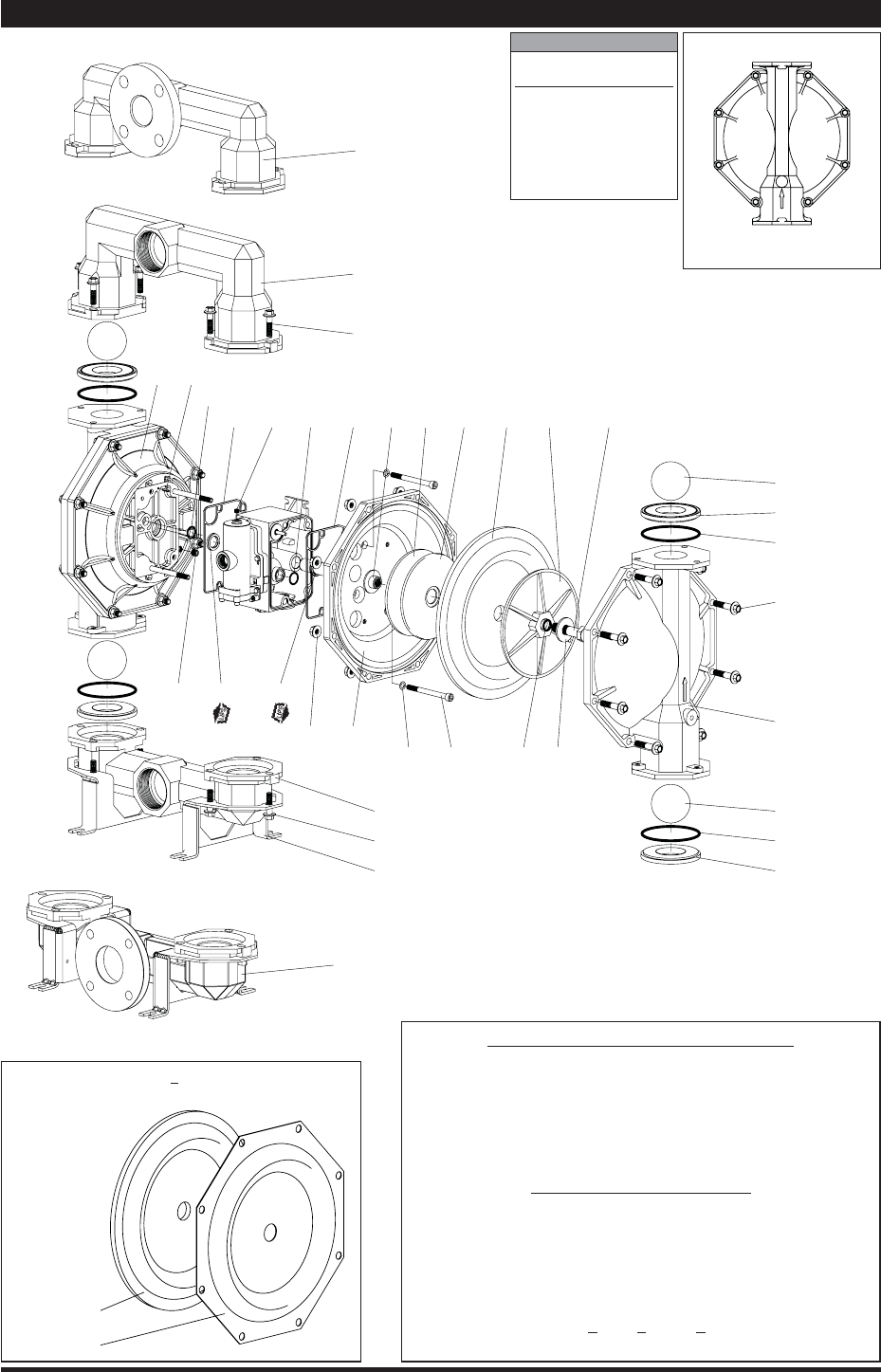

60

32

26

27

15

22

22

21

19

19

21

18168

175

76

70

51 67

9180

131

144

69

61

60

61

26

29

126

144

70

175

14

3

196

26

)

ASSEMBLY TORQUE REQUIREMENTS

(

NOTE: DO NOT OVERTIGHTEN FASTENERS.

ALL FASTENERS ARE METRIC.

(14) cap screw, 65 - 70 ft lbs (88.1 - 94.9 Nm).

(26) screw, 60 - 70 ft lbs (81.3 - 94.9 Nm).

(27) screw, 60 - 70 ft lbs (88.1 - 94.9 Nm).

(131) screw, 35 - 40 ft lbs (47.5 - 54.2 Nm).

LUBRICATION / SEALANTS

c

Apply Lubriplate FML-2 grease to all “O” rings, “U” cups and mating parts.

d

Apply Loctite® 271™ to threads.

e

Apply anti-seize compound to threads and bolt and nut flange heads

which contact pump case when using stainless steel fasteners.

f

Apply Loctite 262™ to threads at assembly.

g

Apply PTFE tape to threads.

h

Apply Loctite 572™ to threads.

i

Not used with PX30X-XXX-AXX-C, -CXX and -GXX.

Note: Lubriplate FML-2 is a white food grade petroleum grease.

PARTS LIST / PX30X-XXX-XXX-C FLUID SECTION

FOR THE AIR MO-

TOR SECTION, SEE

PAGES 6 & 7.

Figure 2

View for PX30X-XXX-XXT-C (PTFE diaphragm) con-

guration only.

(Santoprene)

8

(PTFE)

7

COLOR CODE

Diaphragm Ball

Material Color Color

Hytrel Cream Cream

Nitrile Black Red (•)

Santoprene Tan Tan

Santoprene Green N / A

(backup)

PTFE White White

Viton Yellow (-) Yellow (•)

(-) Stripe (•) Dot

Torque Sequence

3

2

7

5

1

8

6

4