PD15P-XPage 6 of 8

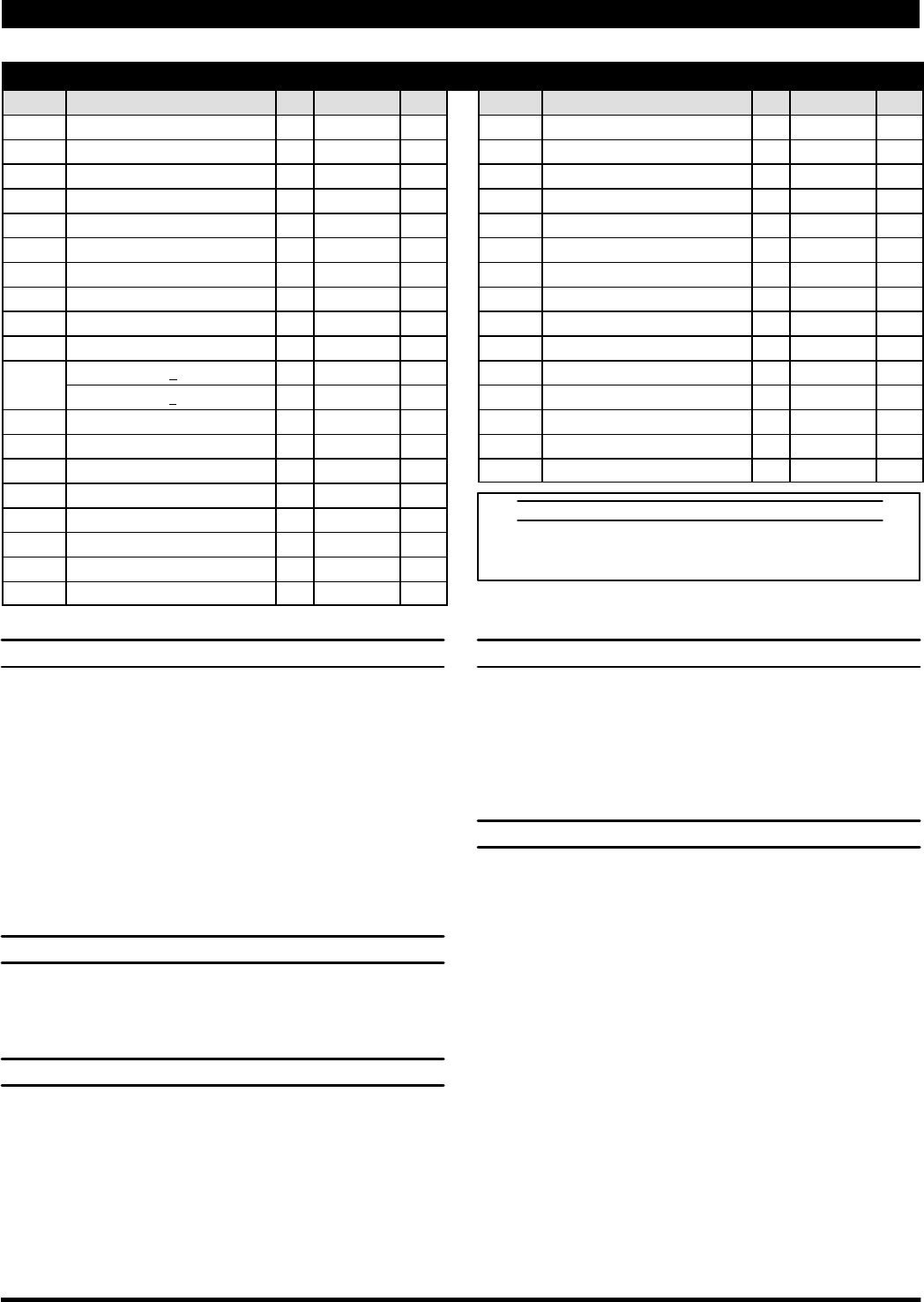

PARTS LIST / PX15P-X AIR SECTION

n Indicates parts included in 637389 Air Section Service Kit shown below and items (70), (144), (175) and (180) shown on page 4.

AIR MOTOR PARTS

Item Description (size) Qty Part No. [Mtl] Item Description (size) Qty Part No. [Mtl]

101 Center Body (1) 95970 [P]

103 Bushing (1) 95823 [D]

105 Screw (M6x1-6gx130mm) (4) 95886 [SS]

107 End Plate (2) 95840 [SS]

111 Spool (1) 96293 [D]

118 Actuator Pin (2) 95839 [SS]

121 Sleeve (2) 95123 [D]

n 132 Gasket (1) 96170 [B]

133 Washer (M6) (6) 95931 [SS]

134 Screw (M6x1-6gx20mm) (6) 95887 [SS]

135 Valve Block (PD15P-XXS-XXX) (1) 95834-1 [P]

(PE15P-XXS-XXX) (1) 95834-2 [P]

136 End Cap (1) 95833 [P]

n 137 Gasket (1) 95844 [B]

n 138 “U” Cup (3/16” x 1-5/8” o.d.) (1) Y186-53 [B]

n 139 “U” Cup (3/16” x 1-1/8” o.d.) (1) Y186-49 [B]

140 Valve Insert (1) 95838 [AO]

141 V alve Plate (1) 95837 [AO]

n 166 Gasket (1) 96171 [B]

n 167 Pilot Piston (includes 168 and 169) (1) 67164 [D]

168 “O” Ring (3/32” x 5/8” o.d.) (2) 94433 [U]

169 “U” Cup (1/8” x 7/8” o.d.) (1) Y240-9 [B]

170 Piston Sleeve (1) 94081 [Br]

n 171 “O” Ring (3/32” x 1-1/8” o.d.) (1) Y325-119 [B]

n 172 “O” Ring (1/16” x 1-1/8” o.d.) (1) Y325-22 [B]

n 173 “O” Ring (3/32” x 1-3/8” o.d.) (2) Y325-123 [B]

K n 174 “O” Ring (1/8” x 1/2” o.d.) (2) Y325-202 [B]

n 176 Diaphragm (check valve) (2) 95845 [SP]

181 Roll Pin (5/32” o.d. x 1/2” long) (4) Y178-52-S [SS]

n 200 Gasket (1) 95842 [B]

201 Muffler (1) 93139 [P]

233 Adapter Plate (1) 95832 [P]

236 Nut (M6x1-6h) (4) 95924 [SS]

L n Lubriplate FML-2 Grease (1) 94276

Lubriplate Grease Packets (10) 637308

MATERIAL CODE

[AO] = Alumina Oxide [D] = Acetal [SS] = Stainless Steel

[B] = Nitrile [P] = Polypropylene [U] = Polyurethane

[Br] = Brass [SP] = Santoprene

K Fluid Section Service Kit parts, see page 4.

AIR MOTOR SECTION SERVICE

Service is divided into two parts - 1. Pilot Valve, 2. Major Valve.

GENERAL REASSEMBLY NOTES:

S Air Motor Section Service is continued from Fluid Section repair.

S Inspect and replace old parts with new parts as necessary. Look for

deep scratches on surfaces, and nicks or cuts in “O” rings.

S Take precautions to prevent cutting “O” rings upon installation.

S Lubricate “O” rings with Lubriplate FML-2 grease.

S Do not over-tighten fasteners, refer to torque specification block on

view.

S Re-torque fasteners following restart.

S SERVICE TOOLS -- To aid in the installation of (168) “O” rings onto

the (167) pilot piston, use tool # 204130-T, available from ARO.

PILOT VALVE DISASSEMBLY

1. A light tapping on (118) should expose the opposite (121) sleeve,

(167) pilot piston and other parts.

2. Remove (170) sleeve, inspect inner bore of sleeve for damage.

PILOT VALVE REASSEMBLY

1. Clean and lubricate parts not being replaced from service kit.

2. Install new (171 and 172) “O” rings, replace (170) sleeve.

3. Install new (168) “O” rings and(169) seal - Note the lip direction. Lu-

bricate and replace (167).

4. Reassemble remaining parts, replace (173 and 174) “O” rings.

MAJOR VALVE DISASSEMBLY

1. Remove (135) valve block and (233) adapter plate, exposing (132

and 166) gaskets and (176) checks.

2. Insert asmall flatbladescrewdriver intothe notch inthe side of(135)

valve blockand pushin ontab toremove(233)adapter plate,releas-

ing (140) valve insert, (141) valve plate and (200) gasket.

3. Remove (136) end cap and (137) gasket, releasing (111) spool.

MAJOR VALVE REASSEMBLY

1. Install new (138 and 139) “U” cups on (111) spool -- LIPS MUST

FACE EACH OTHER.

2. Insert (111) spool into (135) valve block.

3. Install (137)gasket on (136)end cap andassemble end capto (135)

valve block, securing with (107) end plates and (105) screws.

NOTE: Tighten (105) screws to 35 - 40 in. lbs (4.0 - 4.5 Nm).

4. Install (140)valveinsert and (141)valveplate into (135) valveblock.

NOTE: Assemble (140) valve insert with “dished” side toward (141)

valve plate. Assemble (141) valve plate with part number identifica-

tion toward (140) valve insert.

5. Assemble (200)gasket and (233)adapter plate to(135) valve block.

NOTE: Assemble (233) adapter plate with notched side down.

6. Assemble (132 and 166) gaskets and (176) checks and to (101)

body.

7. Assemble (135) valve block and components to (101) body, secur-

ing with (134) screws. NOTE: Tighten (134) screws to 35 - 40 in. lbs

(4.0 - 4.5 Nm).