Page 8 of 8 PD05P-XXX-XXX-B (en)

PN 97999-1164

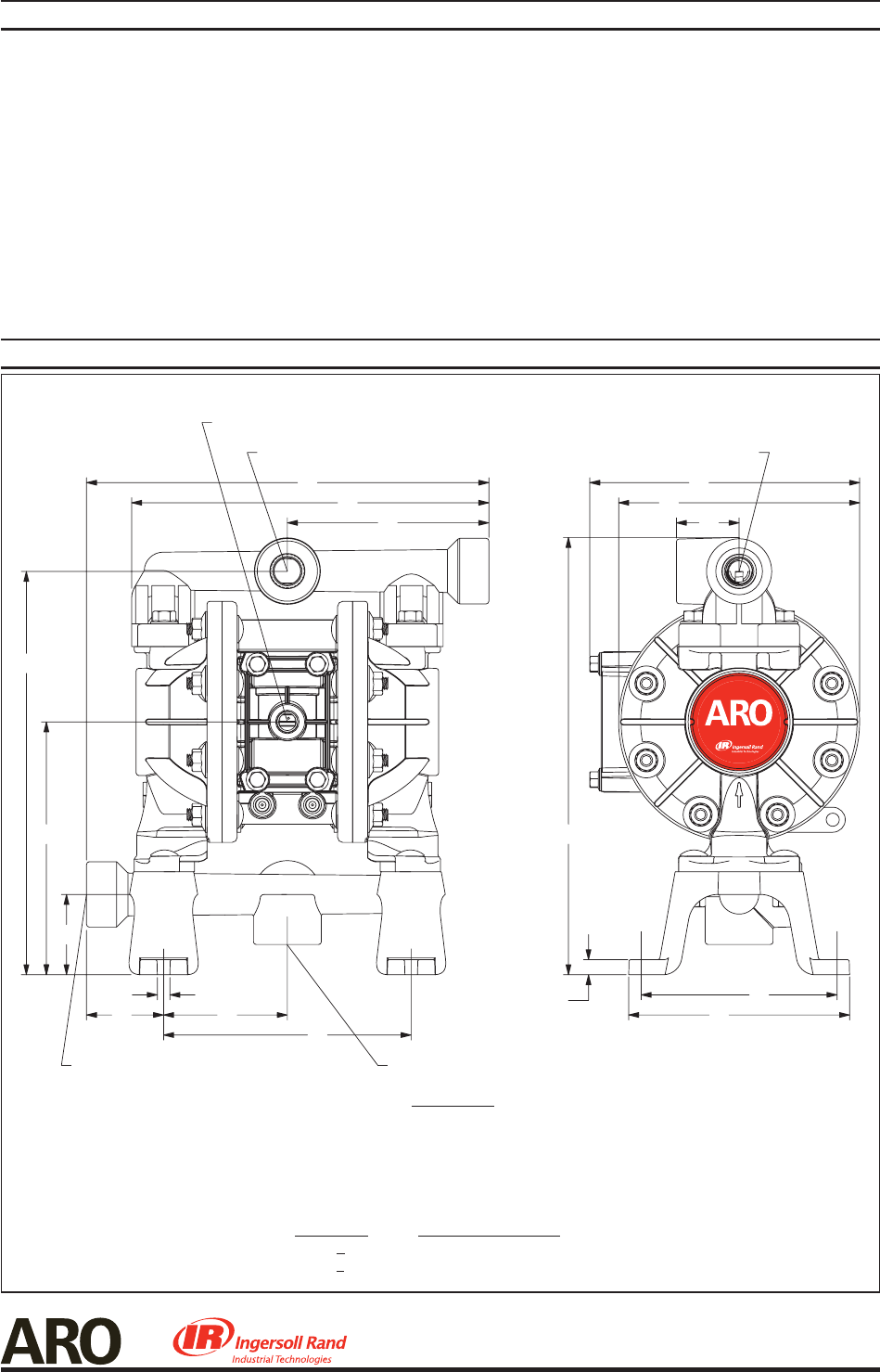

DIMENSIONAL DATA

DIMENSIONS

A - 10-1/32” (254.8 mm)

B - 10-3/32” (256.1 mm)

C - 6-3/16” (157.1 mm)

D - 2” (51.0 mm)

E - 6-3/4” (171.0 mm)

F - 6-1/32” (153.1 mm)

G - 10-29/32” (276.8 mm)

H - 4-29/32” (124.2 mm)

J - 5-17/32” (140.2 mm)

K - 5/16” (8.0 mm)

L - 1-15/16” (48.9 mm)

M - 3/8” (9.6 mm)

N - 6-11/32” (160.5 mm)

P - 8-29/32” (225.9 mm)

Q - 5-1/32” (127.4 mm)

Figure 5

Dimensions shown are for reference only, they are displayed in inches and millimeters (mm).

Pump Model “U” Material Inlet / Outlet

PD05P-AXS-XXX-B 1/2 - 14 N.P.T.F. - 1

PD05P-BXS-XXX-B Rp 1/2 (1/2 - 14 BSP, parallel)

R - 3-3/32” (78.5 mm)

S - 1-9/16” (39.7 mm)

T - 1/4 - 18 P.T.F. SAE Short

U - see below

TROUBLE SHOOTING

Product discharged from exhaust outlet.

Check for diaphragm rupture.

Check tightness of (6) diaphragm nut.

Air bubbles in product discharge.

Check connections of suction plumbing.

Check “O” rings between intake manifold and uid caps.

Check tightness of (6) diaphragm nut.

Motor blows air out main exhaust when stalled on either

stroke.

Check “U” cups on (111) spool in major valve.

Check (141) valve plate and (140) insert for wear.

Check (169) “U” cup on (167) pilot piston.

Low output volume.

Check air supply.

Check for plugged outlet hose.

For the pump to prime itself, it must be mounted in the vertical

position so that the balls will check by gravity.

Check for pump cavitation - suction pipe should be sized at

least as large as the inlet thread diameter of the pump for

proper ow if high viscosity uids are being pumped. Suction

hose must be a non-collapsing type, capable of pulling a high

volume.

Check all joints on the inlet manifolds and suction connections.

These must be air tight.

Inspect the pump for solid objects lodged in the diaphragm

chamber or the seat area.

M

H

J

G

S

F

E

LR

C

D

N

B

Q

P

A

K

U - Material Outlet

T - Air Inlet

U - Material Inlet

U - Material Inlet

U - Material Outlet