PN 97999-1132

LM2203A-X-CPage4of4

PLACING INTO SERVICE

AIR AND LUBRICATION REQUIREMENTS

Filtered air will help extend thelife of the pump, allowing the pump to op-

erate more efficiently and yield longer service life to moving parts and

mechanisms.

• Install an air linefilter toprovidegood qualityclean and dryair. Install

it up stream from the regulator.

• Use an air regulator on the air supply to control the pump cycle rate.

Install the regulator as close as possible to the pump.

• In mostinstallations, lubrication isnot required. If thepump needs to

have lubrication, install an air linelubricator andsupply itwith a good

grade of non-detergent oil or other lubricant compatible with Nitrile

seals and set at a rate not to exceed one drop per minute.

INSTALLATION

• Mount and secure the pump as required for the application.

• Attach a ground wire from the pump ground screw to a suitable

ground.

• Connect afluid hoseto the pumpoutlet. Inmost casesa pipesealant

should be used on thread connection. Tighten all fittings. Use cau-

tion not to damage threads.

OPERATION

START-UP

1. Turn the air regulator to “0” pressure setting.

2. Immerse the lower pump end into the material.

3. Open the dispensing device.

4. Start the pump cycling slowly by raising the pressure to 20 - 30p.s.i.

(1.4 - 2.1 bar).

5. Close the dispensing device. Allow the pump to stall and build line

pressure. Check for any leaks and tighten fittings as needed.Adjust

pressure as required for the application.

SHUTDOWN

• Disconnect theair supply from thepump if it isto be inactivefor a few

hours. Open the dispensing device to relieve line pressure.

SER VICE

PUMP DISASSEMBLY / REASSEMBLY

NOTICE: The unique design of this pump allows for quick basic pump

service without total removal from the drum (refer to the views below).

DISASSEMBLY

- Allthreads areright hand.Refer tofigure 2.These

proceduresare fortheinstallation ofrepairkitparts. Disconnectair

supply and relieve all system pressure

prior to servicing. Carefully

remove theparts, inspect partsfor damage,nicks orexcessive wearand

determine if any parts will need replacement.

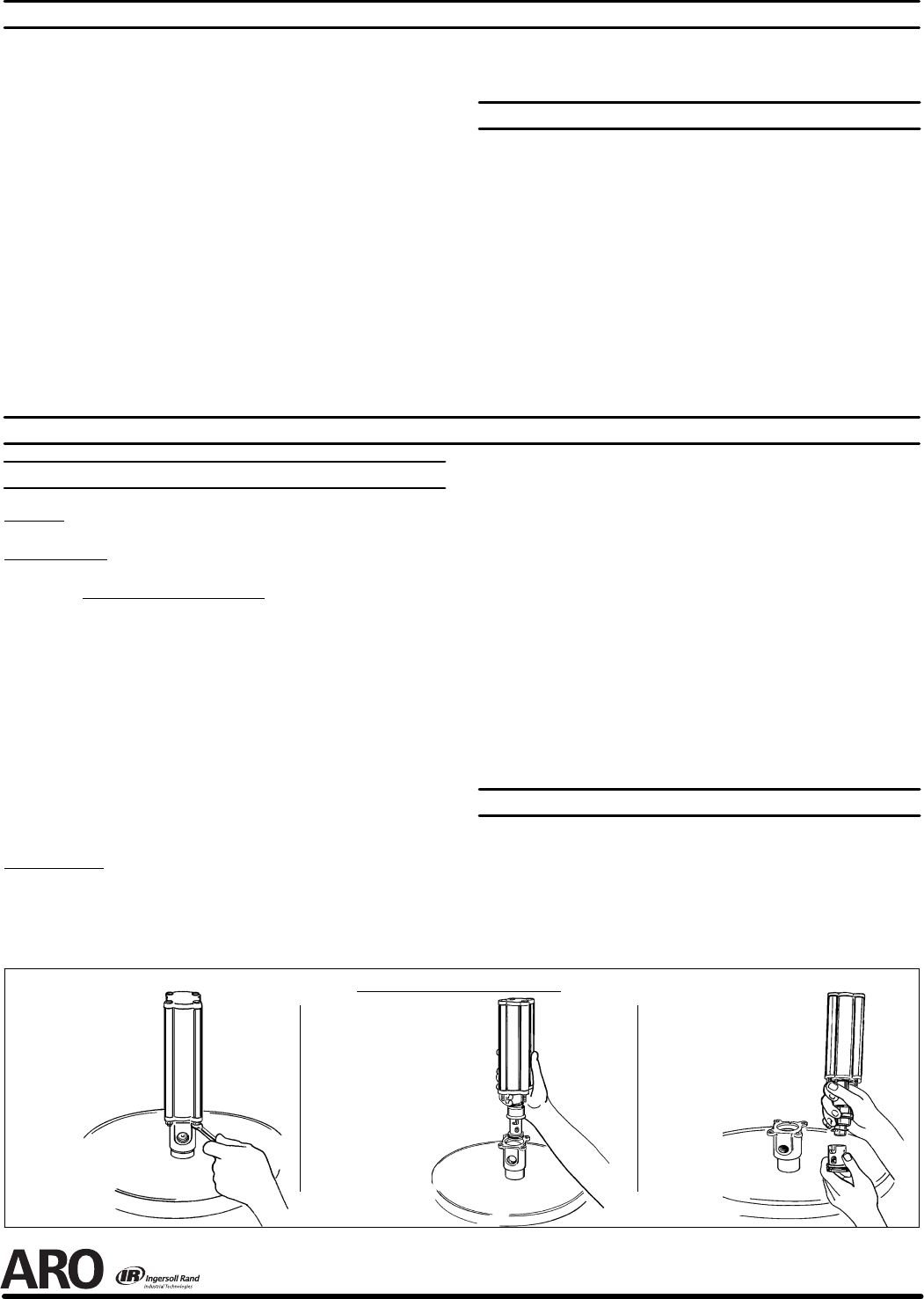

Follow the three disassembly steps in the detail views below and place

the pump on a clean bench.

1. Remove (1) bolts. Remove (18) packing,(17) bushing and (16) “O” ring.

2. Remove (36) adapter, releasing (10) muffler housing.

3. Grasp the (11) cylinder and remove the (20, 14) piston assembly.

4. Remove(15) lower cap and (3) track gasket. Remove (12) retaining

ring and (48) washer, then pull (14) piston off (20) piston rod.

5. Remove (2) cap and (3) track gasket. Push on the large o.d. end of

the (7) spoolto removethe (4)sleeve. Grabthe noseof (7) spooland

pull out. Repeat for other sleeve and spool.

REASSEMBLY

- Thoroughly clean and lubricate all seals and

bores with Shell Gadus S2 U1000 upon assembly. Replace all soft

parts with new ones included in the repair kit.

Note: Refer to the illustration (figure 2) for “U” cup lip seal direction.

1. Replace the seals on both the (7) spools and (4) sleeves.

2. Locate the valve chamber on the (11) cylinder where the 3/8’’ dia.

hole is located and install one of the (4) sleeves. Insert the (7) spool

from the opposite end. Next, install the remaining sleeve and spool.

3. Replace the (3) track gasket and install (2) cap.

4. Replacethe (13) piston “U” cups (refer to figure 2for proper orienta-

tion). Replace the (19) “O” ring and assemble (14) piston to(20) pis-

ton rod and retain with (48) washer and (12) retaining ring.

5. Install the (20, 14) piston assembly using great care to collapse the

outer lip of the second “U” cup, allowing it to slip into the cylinder.

6. Replace the (3) track gasket and install the (15) cap. Install the (16)

“O” ring onto the piston rod, replace (17) bushing and (18) packing.

7. Replace the (25) “O” ring and re-attach the (24) inner check.

8. Slide the pump assembly back into the (26) base / lower pump sec-

tion. Pressthe sectionstogether andalignthe airinlet andpump out-

let as required and replace the four(1) bolts and (27) nuts(tighten to

80 in. lbs (9 Nm).

TROUBLE SHOOTING

If the pump will not cycle or will not deliver material.

• Be certainto check fornon-pump problemsincluding kinked,restric-

tive orplugged inlet/ outlethose ordispensing device.Depressurize

the pump system and clean out any obstructions in the inlet / outlet

material lines.

• Check all seals, including track gaskets.

• Check direction of “U” cup lips.

C) Unlock the (24) inner

check from the piston

rod.

Figure 5

Figure 4

B) Grasp the lower motor cap

and pull out the motor and

upper section of the lower

section.

PUMP DISASSEMBLY DETAIL

Figure 3

A) Remove the four

nuts from the base

of the Air Motor.