66605X-X (en)Page 6of 8

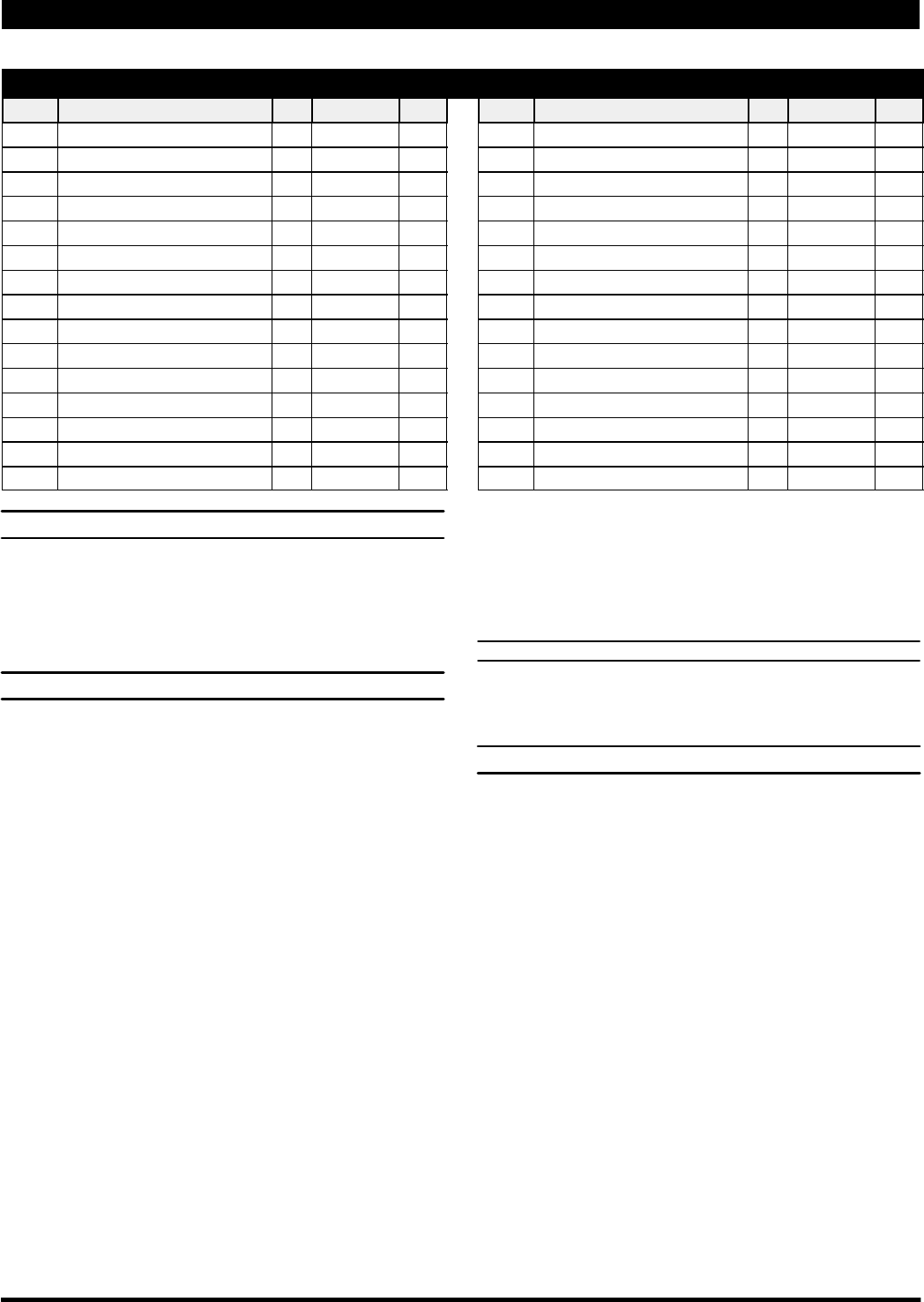

PARTS LIST / 66605X -X AIR MOTOR SECTION

n Indicates parts included in 637141 Air Section Repair Kit.

AIR SECTION PARTS

Item Description (size) Qty Part No. [Mtl] Item Description (size) Qty Part No. [Mtl]

101 Motor Body (1) 93091 [P]

n 102 “O” Ring(3/32” x1”o.d.) (2) Y325-117 [B]

j 103 Sleeve (1) 93087 [Bz]

j 104 Snap Ring (13/16”) (2) 37285 [C]

111 Spool (1) 93085 [D]

118 Pilot Rod (1) 93088 [C]

n 119 “O” Ring (1/8”x 3/4”o.d.) (4) 93075 [U]

j 120 Spacer (3) 115959 [Z]

n 122 Snap Ring (1/2”) (2) 77802 [C]

124 Stud (5/16” - 18x 1-17/32”) (see page 5) (8) 93249 [SS]

129 Muffler Assembly (1) 66972 [P]

129l Exhaust Cover(see note2) 93092 [PS]

n 130 Gasket (1) 93107 [SY]

131 Bolt(5/16” -18 x1-1/4”) (8) 93095 [SS]

n 132 Gasket(see note1) (1) 93339-1 [B]

133 Washer (9/32”i.d.) (4) 93096 [SS]

134 Bolt (1/4”-20x5”) (4) Y6-419-T [SS]

135 Valve Block (1) 93090 [P]

136 Plug (1) 93086 [D]

n 137 “O” Ring (3/32”x 1-1/2” o.d.) (1) Y325-125 [B]

n 138 Packing, “U” Cup(1/8”x1” o.d.) (1) 94395 [U]

n 139 Packing, “U” Cup (1/8” x1.427”o.d.) (1) 96383 [B]

n 140 Valve Insert (1) 93276 [CK]

n 141 Valve Plate (1) 93275 [CK]

142 Washer (2) 116038 [Z]

143 Plate (2) 93089 [SS]

201 Muffler(seenote2) 93110 [C]

n Key-Lube “O” Ring Lubricant 93706-1

10 Pack of Key-Lube 637175

DIAPHRAGM PUMP SERVICE

GENERAL SERVICE NOTES:

S Inspect andreplace oldpartswith newparts as necessary. Lookfor

deep scratches on metallic surfaces, and nicks or cuts in “O” rings.

S 7/16” wrench, 1/2” wrench, 7/16” socket, 1/2” socket, torque

wrench (measuring inch pounds), “O” ring pick.

FLUID SECTION DISASSEMBLY

1. Remove (34) top manifold / (36) swivel assembly.

Note: Manifold options involve single piece manifolds (60 / 61) or three

piece swivel type manifolds with clamps.

2. Remove (41) ball cages, (22) balls, (19 and 20) “O” rings and (21)

seats. Note: If cages are difficult to remove at this step, it may be

helpful to proceed through step 5 and remove them once they are

accessible from the inside of the fluid cap.

3. Remove (35) bottom manifolds / (36) swivel assembly.

4. Remove (19) “O” rings, (21) seats and (22) balls.

5. Remove (15) fluid caps.

6. Remove (6) diaphragm nut, (8) [(7) PTFE models only] dia-

phragm(s) and(5) diaphragm washer from(1) diaphragm connect-

ing rod.

7. Remove (1) connecting rod from air motor.

8. Carefully remove remaining (6) diaphragm nut, (8) [(7) PTFE mod-

els] diaphragm and (5)diaphragm washer from (1) connecting rod.

Do not mar surface of connecting rod.

9. Remove (2) “O” ring from connecting rod.

10. Remove (37)clamps fromtop and bottommanifold / swivelassem-

blies.

11. Remove (33) “O” rings from (36) swivels.

Note1:Partno.93339-1one-piecegasketreplacesthefollowingparts(notshown)inmod-

els manufactured prior to October 1988, Y325-10 (4), Y325-12, 93093, 93094,

Y325-8.

Note 2:The (129

l) exhaustcover and(201) mufflerwere standarduntil 9/92.They are

available separately forservice or piped exhaust applications.

Note3:Amajorvalveserviceassemblyisavailableseparatelywhichincludesitems:111,

132, 135- 141. Orderpart no.66362.

MATERIAL CODE

[B]= Nitrile [D]= Acetal [SY] = Syn-Seal

[Bz] = Bronze [P]= Polypropylene [U] = Polyurethane

[C] = CarbonSteel [PS]= Polyester [Z] = Zinc

[CK]= Ceramic [SS]= Stainless Steel

FLUID SECTION REASSEMBLY

S Reassemble in reverse order.

S Lubricate(1)connectingrodand(2)“O”ringwithKey-Lubeorequiv-

alent “O” ring lubricant.

S Install (5) diaphragm washers with i.d. chamfer toward diaphragm.

S WhenreplacingPTFEdiaphragms,installthe93465Santoprenedi-

aphragm behind the PTFE diaphragm.

S When installing (41) cage, ball guides must line up with notches in

(21) seat to prevent damage.

S Beforeinstalling(35),(34)manifolds,(19)“O”ringshouldbeproper-

ly seated on the o.d. of (41) ball cage.

S Before tightening (39) nut and (38) carriage bolts on (36) swivels,

attach the manifold / swivel assembly to the fluid caps. Rotate (36)

swiveltodesiredpositionandtighteneachofthenutsapproximately

8 - 9 turns, then finish tightening (29) nuts.

V “SmartParts”, keepthese items onhand in addition tothe service kits for fastrepair andreduction ofdown time.