PN97999Ć062

662400ĆC

PAGE2OF2

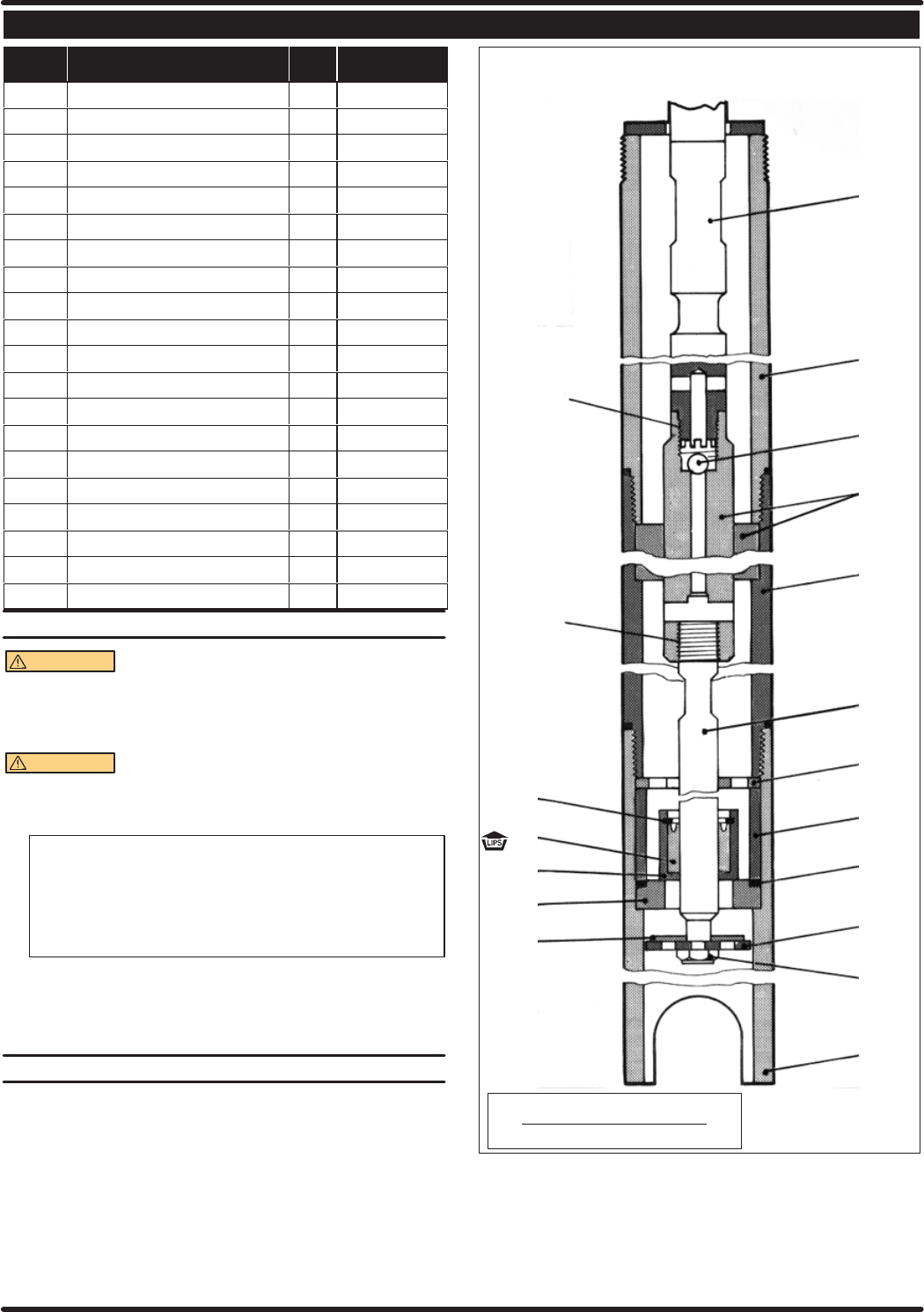

PARTS LIST / LOWER PUMP END

ITEM DESCRIPTION (Size in Inches) QTY PART NO.

1 Rod (662400ĆC) (1) 90127

(662402) (1) 92291

2 Tube (662400ĆC) (1) 90128

(662402) (1) 92292

3 Ball (1) Y16Ć211

4 Piston Assembly (1) 65036

5 Tube (1) 90135

*6 Rod (1) 90131

*7 Washer (1) 90136

8 Sleeve (1) 4170

*9 Washer (1) 92845

10 Washer (1) 90138

11 Nut (1) 95977302

12 Tube (1) 90129

*13 Ring (1) Y147Ć77

*14 Packing (1) 90757

15 Body (1) 90756

16 Seat (1) 4169

17 Washer (1) 90133

*

Parts in Repair Kit 61052

OPERATING

AND SAFETY PRECAUTIONS

WARNING

EXCESSIVE INLET PRESSURE. Can cause exĆ

plosion resultinginsevereinjuryordeath.DonotexceedmaxĆ

imum operating pressure of 7500 p.s.i. (517 bar) at 150 p.s.i.

(10 bar) inlet air pressure. Do not run pump without using a

regulator to limit air supply pressure to the pump.

WARNING

EXCESSIVE MATERIAL PRESSURE. Can cause

equipment failure resulting in severe injury or property damĆ

age. Do not exceed the maximum material pressure of any

component in the system.

PUMPRATIO X

INLETPRESSURETOPUMPMOTOR

=

MAXIMUMPUMP

FLUIDPRESSURE

Pumpratioisanexpressionoftherelationshipbetweenthepumpmotorareaand

the lower pumpend area. EXAMPLE:When 150 p.s.i. (10bar) inlet pressure is

suppliedtothemotorofa50:1ratiopumpitwilldevelopamaximumof7500p.s.i.

(517 bar)fluidpressure (atno flow)- as thefluidcontrol isopened, theflow rate

will increase asthe motor cyclerate increases to keepup with thedemand.

NOTICE: Thermal expansion canoccur when thefluid in themateĆ

rial lines is exposed to elevated temperatures. Example: Material

lines locatedin a nonĆinsulatedroof areacan warmdueto sunlight.

Install a pressure relief valve in the pumping system.

TROUBLE SHOOTING

No material at outlet. (Pump continuously cycles).

• Empty material supply. Disconnect the air, replenish the material

supply.

• Foreign matter is holding foot valve seats open in the lower pump

tube assembly. Remove lower pump tube assembly and clean

valve seats.

Pump operates sluggishly, tends to stick when air is applied or

control is opened.

• Air motor is dirty or lacks lubrication. Clean air motor.

• Insufficient air pressure or volume of air. Check air supply.

. TORQUE REQUIREMENTS ,

(12)260 Ć300 ftlbs (352.6Ć 406.8Nm)

12 ,

11

10

9*

8

7*

6*

5

4

*13

*14

15

16

17

3

2

1

V

V

V Clean threads with

solvent and apply

Loctite 271 Sealant

to threads.

Air bypasses through exhaust port.

• Foreign matter is holding air valve open or lacks lubrication. ConĆ

sult factory for nearest Service Center.

Motor stalls.

• Foreign matter inpump, hose,control valve orspraytip obstructing

material flow. Check material supply hose and control valve tip.