650929-X

PUMP OPTION DESCRIPTION CHART

650929--X

PACKING MATERIAL

PLUNGER TYPE

SPRING ARRANGEMENT

PACKING MATERIAL (PACKINGSAREUPPERANDLOWERUNLESSNOTED)

3 GLASSFILLEDPTFE P UHMW--PE/PTFE STAG’D (UPPER)

C UHMW--PE UHMW--PE(LOWER)

G UHMW--PE/LEATHERSTAG’D R PTFE/UHMW--PESTAG’D(UPPER)

PTFE(LOWER)

SPRING ARRANGEMENT

4

MULTIPLEWAVESPRING

PLUNGER TYPE

3

HDSS W/HDCHROMEPLATING

43

GENERAL DESCRIPTION

WARNING

HAZARDOUS PRESSURE. Do not exceed maxi-

mum operating pressure of 2054 psi (142 bar) at 1200 psi (83

bar) inlet hydraulic pressure.

PUMP RATIO X MAXIMUM PUMP

INLET PRESSURE TO PUMP MOTOR

= FLUID PRESSURE

Pumpratiois anexpressionofthe relationshipbetweenthe pumpmotorareaandthe

lowerpumpendarea.EXAMPLE:When150p.s.i.(10.3bar)inletpressureissupplied

tothemotorofa5:1ratiopumpitwilldevelopamaximumof750p.s.i.(52bar)fluidpres-

sure(atnoflow)--asthefluidcontrolisopened,theflowratewillincreaseasthemotor

cycle rate increases to keepup withthe demand.

WARNING

Refer to general information sheet for additional

safety precautions and important information.

• The Two--Ballpumps areprimarilydesignedfor the pumpingofme-

dium viscosityfluids compatible withcarbon steel. T helower pump

is designed for easy priming and the double acting feature is stan-

dard in all ARO industrial pumps. Material is delivered to thepump

discharge outlet on both the up and down stroke.

• The motoris connectedto thelower pumpend byaspacer section.

This allows for lubrication of the upper packinggland and prevents

motorcontaminationbecauseofnormalwearandeventualleakage

through thematerial packinggland. Besure the solvent cupis ade-

quatelyfilled with lubricant toprotecttheupper packingsandinsure

longest service life.

TROUBLE SHOOTING

Pump problems can occur in either the Hydraulic Motor Section or the

LowerPump EndSection,use these basicguidelinestohelpdetermine

which section is affected.

If the pump will not cycle.

• Be certain to first check for non--pump problems including kinked,

restrictiveorpluggedinlet/outlethoseordispensingdevice.Depres-

surize the pumpsystem and clean outany obstructions inthe inlet/

outlet material lines.

• Refer tothe motormanual fortroubleshooting ifthe pumpdoesnot

cycle and/or hydraulic fluid leaks from the hydraulic motor.

If the pump cycles but does not deliver material.

• Refer to the lower pump end manual for further trouble shooting.

PUMP CONNECTION -- UPPER / LOWER

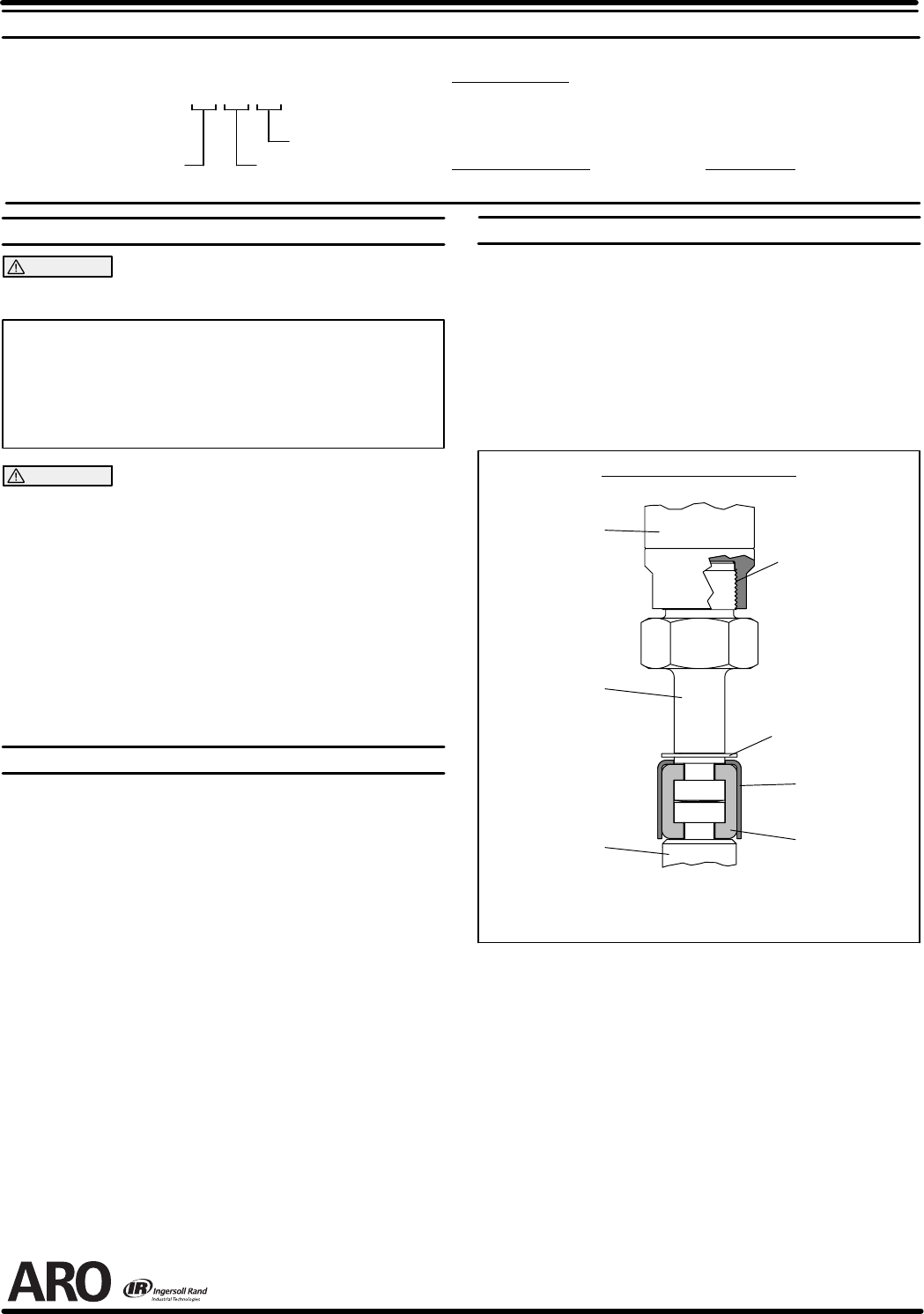

NOTE: All threads are right hand.

1. Lay the pump assembly on a workbench.

2. Remove the three screws andwashers from the three spacer rods

(see figure 1).

3. Pull thehydraulicmotor fromthe lower pumpend untilmotor piston

rodis inthe‘‘down” positionandlower pumpendrod is in ‘‘up”posi-

tion.

4. Usinge--ringpliers,slidetheretainingringupfarenoughtoallowthe

sleeve tomove upward and releasethe two connectors (see figure

2).

Lower Pump

Piston Rod

Pump Motor

Piston Rod

Retaining Ring

90102

Sleeve

90109

Connector

90096 (2)

PUMP CONNECTOR DETAIL

FIGURE 2

Adapter

93344--1

APPLY LOCTITE

271

REASSEMBLY

1. Align the pump motor with the lower pump end.

2. Installthetwoconnectorsandretainwiththesleeve,slidetheretain-

ing ring back into position.

3. Reinstall the spacer rods to the pump motor.

4. Bring the motor and lower pump together and retain with the three

screws and washers.

PN 97999-329