650923-X-B

PUMP OPTION DESCRIPTION CHART

650923--X

PACKING MATERIAL

PLUNGER TYPE

SPRING ARRANGEMENT

PACKING MATERIAL (PACKINGSAREUPPERANDLOWERUNLESSNOTED)

7 GLASS FILLEDPTFE (UPPER) P UHMW--PE/PTFE STAG’D (UPPER)

VIRGINPTFE (LOWER

) UHMW--P E (LOWER)

C UHMW--PE R PTFE/UHMW--PE STAG’D (UPPER)

F UHMW--PE/LEATHER STAG’D (UPPER) PTFE (LOWER)

UHMW--PE (LOWER)

SPRING ARRANGEMENT

4

MULTIPLE WAVESPRING

PLUNGER TYPE

3

HD SSW/HD CHROMEPLATING

43--B

GENERAL DESCRIPTION

WARNING

HAZARDOUS PRESSURE. Do not exceed maxi-

mum operating pressure of 373 psi (25.7 bar) at 1200 psi (83

bar) inlet hydraulic pressure.

PUMP RATIO X MAXIMUM PUMP

INLET PRESSURE TO PUMP MOTOR

= FLUID PRESSURE

Pump ratiois anexpressionof therelationship betweenthe pumpmotorarea andthe

lowerpumpend area.EXAMPLE:When150p.s.i. (10.3bar)inletpressureissupplied

tothemotorofa5:1ratiopumpitwilldevelopamaximumof750p.s.i.(52bar)fluidpres-

sure(atnoflow)--asthefluidcontrolisopened,theflowratewillincreaseasthemotor

cycle rate increases to keep upwith the demand.

WARNING

Refer to general information sheet for additional

safety precautions and important information.

• The Four--Ball pumps are primarily designed for the high volume

transfer oflight and mediumviscosity fluidscompatible withcarbon

steel. The lower pumpis designed for easypriming and the double

actingfeatureisstandardinallAROindustrialpumps.Materialisde-

liveredtothepumpdischargeoutletonboththeupanddownstroke.

• The motor isconnected tothe lower pumpend bya spacer section.

This allows for lubrication of the upper packing gland andprevents

motorcontaminationbecause ofnormalwearand eventualleakage

through thematerial packing gland.Be surethe solvent cupis ade-

quately filledwithlubricant toprotectthe upperpackings andinsure

longest service life.

TROUBLE SHOOTING

Pump problems can occur in either the Hydraulic Motor Section or the

Lower PumpEnd Section,use these basicguidelines tohelpdetermine

which section is affected.

If the pump will not cycle.

• Be certain to first check for non--pump problems including kinked,

restrictiveorpluggedinlet/outlethoseordispensingdevice.Depres-

surize the pump systemand clean outany obstructions in theinlet/

outlet material lines.

• Refer tothe motormanual fortrouble shooting if thepump doesnot

cycle and/or hydraulic fluid leaks from the hydraulic motor.

If the pump cycles but does not deliver material.

• Refer to the lower pump end manual for further trouble shooting.

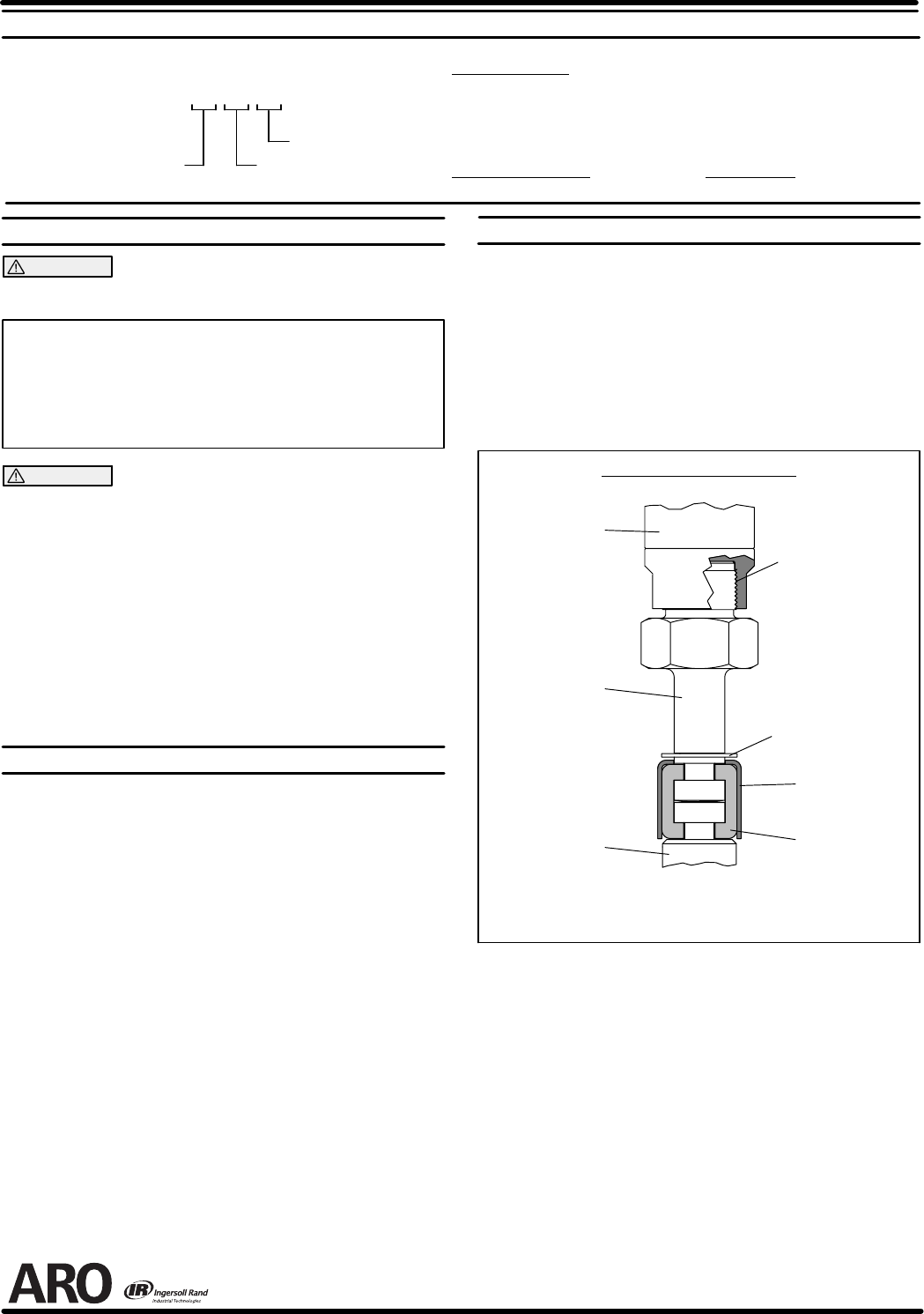

PUMP CONNECTION -- UPPER / LOWER

NOTE: All threads are right hand.

1. Lay the pump assembly on a workbench.

2. Remove the three screws and washersfrom the three spacer rods

(see figure 1).

3. Pull thehydraulic motorfrom thelower pump enduntil motorpiston

rod is in the‘‘down” positionand lowerpump endrodis in ‘‘up” posi-

tion.

4. Usinge--ringpliers,slidetheretainingringupfarenoughtoallowthe

sleeve to moveupward and release thetwo connectors (seefigure

2).

Lower Pump

Piston Rod

Pump Motor

Piston Rod

Retaining Ring

90102

Sleeve

90109

Connector

90096 (2)

PUMP CONNECTOR DETAIL

FIGURE 2

Adapter

93344--1

APPLY LOCTITE

271, TORQUE TO

50 -- 60 FT LBS.

REASSEMBLY

1. Align the pump motor with the lower pump end.

2. Installthetwoconnectorsandretainwiththesleeve,slidetheretain-

ing ring back into position.

3. Reinstall the spacer rods to the pump motor.

4. Bring the motor and lower pump together and retain with the three

screws and washers.

PN 97999-685