650636-X-C

PUMP OPTION DESCRIPTION CHART

650636--X

PACKING MATERIAL

PLUNGER TYPE

SPRING ARRANGEMENT

PACKING MATERIAL (PACKINGSAREUPPERANDLOWERUNLESSNOTED)

7 GLASS FILLEDPTFE (UPPER) P UHMW--PE/PTFE STAG’D(UPPER)

VIRGINPTFE (LOWER

) UHMW--PE (LOWER)

C UHMW--PE R PTFE/UHMW--PE STAG’D (UPPER)

F UHMW--PE/LEATHER STAG’D(UPPER) PTFE (LOWER)

UHMW--PE (LOWER)

SPRING ARRANGEMENT

4

MULTIPLE WAVESPRING

PLUNGER TYPE

3

HD SSW/HD CHROMEPLATING

43--C

GENERAL DESCRIPTION

WARNING

HAZARDOUS PRESSURE. Do not exceed maxi-

mum operating pressure of 450 psi (31.0 bar) at 150 psi (10.3

bar) inlet air pressure.

PUMP RATIO X MAXIMUM PUMP

INLET PRESSURE TO PUMP MOTOR

= FLUID PRESSURE

Pump ratiois anexpressionof therelationship betweenthe pumpmotorarea andthe

lowerpumpend area.EXAMPLE:When150p.s.i. (10.3bar)inletpressureissupplied

to the motorof a3:1 ratiopump it will developa maximum of450 p.s.i.(31.0 bar)fluid

pressure(at noflow) -- asthe fluid control is opened,the flow rate will increaseas the

motor cycle rate increases to keepup with the demand.

WARNING

Refer to general information sheet for additional

safety precautions and important information.

• The Four--Ball pumps are primarily designed for the high volume

transfer oflight andmedium viscosityfluids compatiblewith 400se-

ries stainless s teel. The lower pump is designed for easy priming

and the double acting feature is standard on all ARO industrial

pumps. Material is delivered to the pump discharge outlet on both

the up and down stroke.

• The motor isconnected tothe lower pumpend bya spacer section.

This allows for lubrication of the upper packing gland andprevents

motorcontaminationbecause ofnormalwearand eventualleakage

through thematerial packing gland.Be surethe solvent cupis ade-

quately filledwithlubricant toprotectthe upperpackings andinsure

longest service life.

TROUBLE SHOOTING

Pump problems can occur in either the A ir Motor Section or the Lower

Pump EndSection. Usethese basicguidelines tohelp determinewhich

section is affected.

If the pump will not cycle.

• Be certain to first check for non--pump problems including kinked,

restrictiveorpluggedinlet/outlethoseordispensingdevice.Depres-

surize the pump systemand clean outany obstructions in theinlet/

outlet material lines.

• Refer tothe motormanual fortrouble shooting if thepump doesnot

cycle and/or air leaks from the air motor.

If the pump cycles but does not deliver material.

• Refer to the lower pump end manual for further trouble shooting.

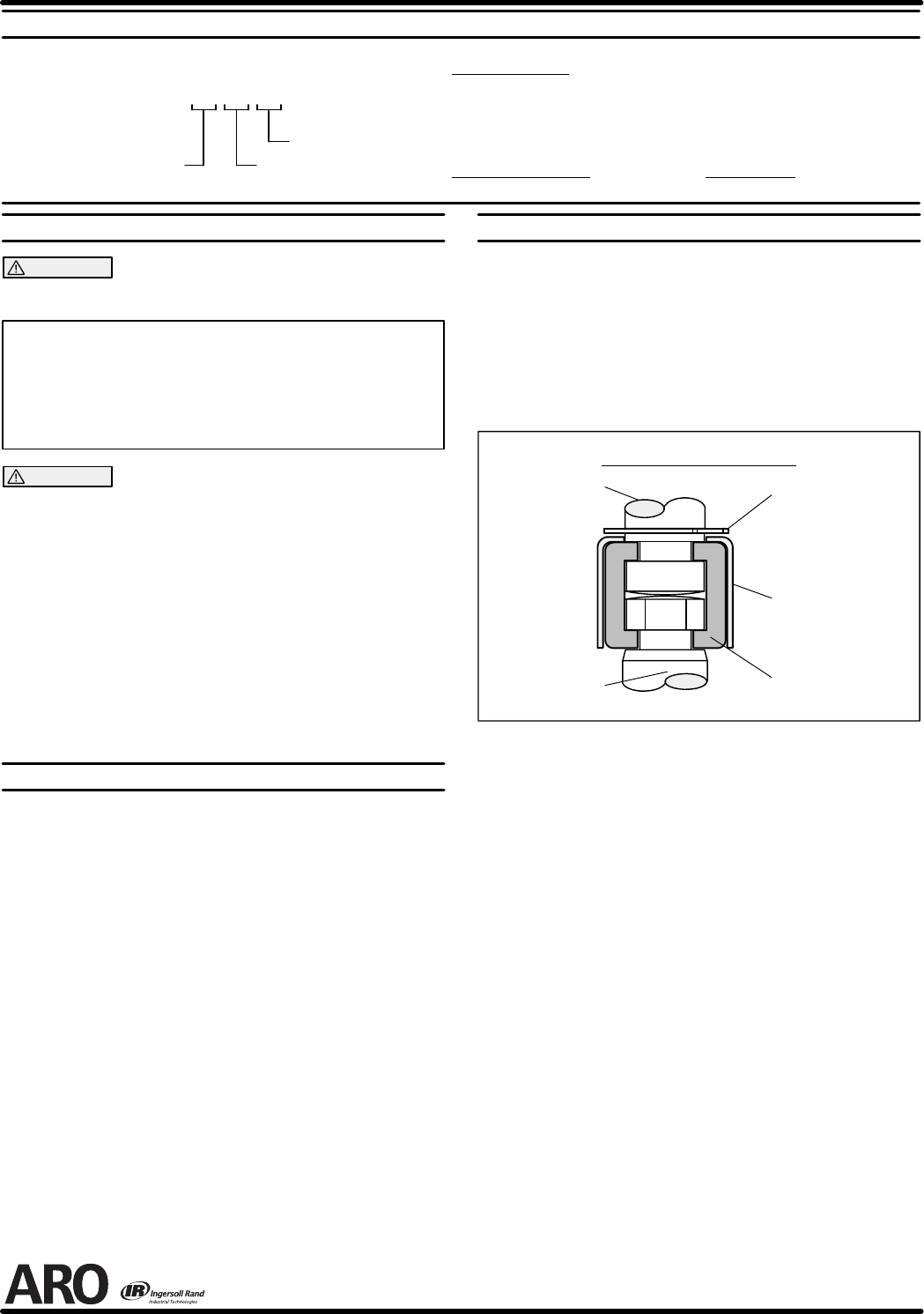

PUMP CONNECTION -- UPPER / LOWER

NOTE: All threads are right hand.

1. Lay the pump assembly on a workbench.

2. Removethethreenutsandwashersfromthethreespacerrods(see

figure 1).

3. Pulltheairmotorfromthelowerpumpenduntilmotorpistonrodisin

the ‘‘down” position and lower pump end rod is in ‘‘up” position.

4. Usinge--ringpliers,slidetheretainingringupfarenoughtoallowthe

sleeve to moveupward and release thetwo connectors (seefigure

2).

Lower Pump

Piston Rod

Pump Motor

Piston Rod

RETAINING RING

91547

SLEEVE 91546

CONNECTOR

91644 (2)

PUMP CONNECTOR DETAIL

FIGURE 2

REASSEMBLY

1. Align the pumpmotorwith thelower pumpend. Positiontheair inlet

of the motor 200_ from the material outlet.

2. Installthetwoconnectorsandretainwiththesleeve,slidetheretain-

ing ring back into position.

3. Reinstall the spacer rods to the pump motor.

4. Bring the motor and lower pump together and retain with the three

nuts and washers.

PN 97999-692