PAGE2OF4 650500-B

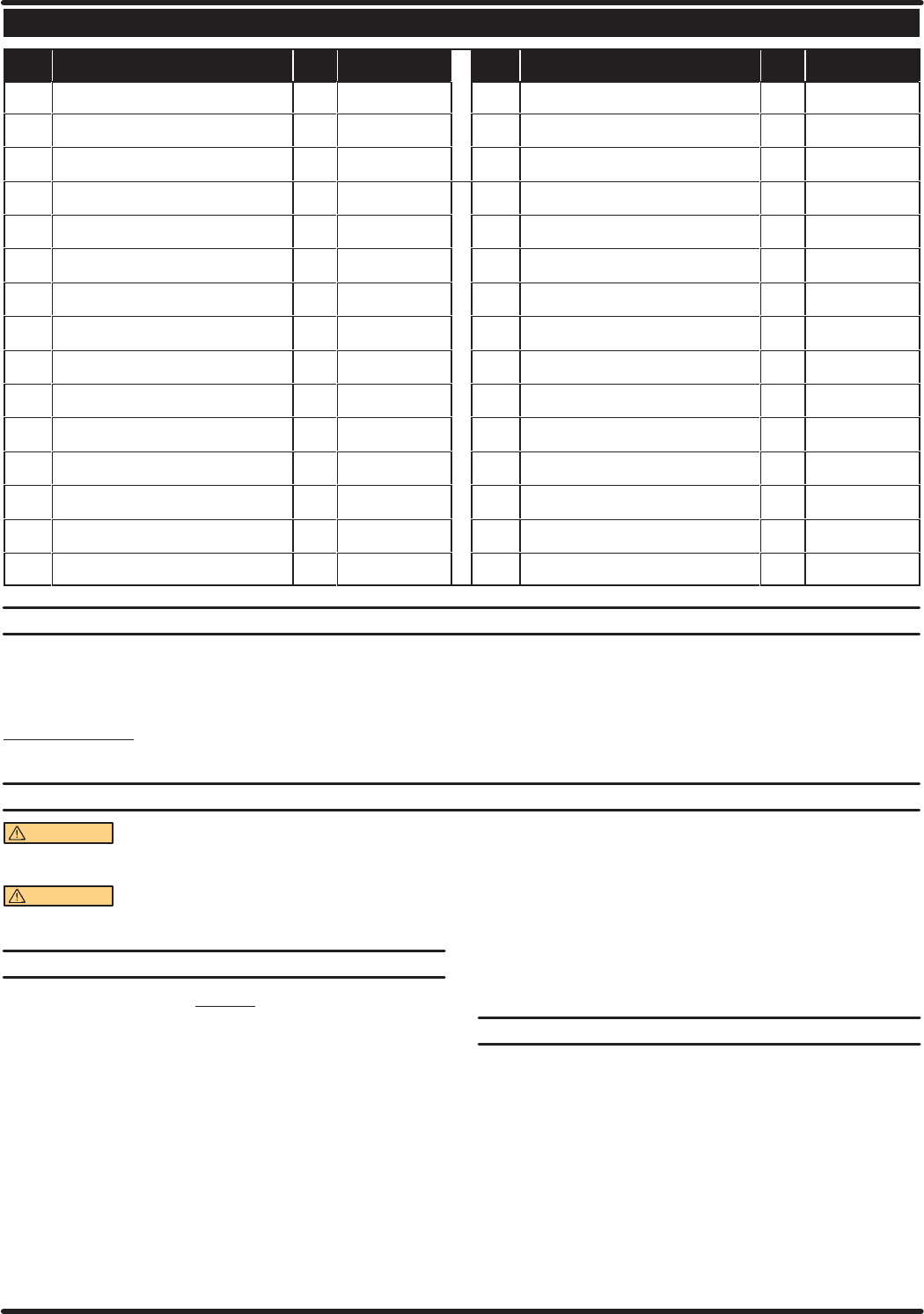

PARTS LIST / 650500–B

Item Description (Size in inches)

(Qty)

Part No. Item Description (Size in inches)

(Qty)

Part No.

1 Plug - Agitator mount (1) 91143

16 Male Elbow (1/4"o.d. tube- 1/4"-18 malethd) (2) 59745-156

2 Bracket (1) 94040 17 5 Gallon Pail (1) 93184

3 Adapter (3/8"-18 male x 1/4"-18 male) (1) 90538 18 Bail (1) 94037

4 Adapter (1/4" - 18 NPTF) (3) 1950 19 Tubing (1/4" o.d. x 8-1/2'' long) (1) 59675-100 f

5 45_ Street Elbow (1/4" - 18 NPT) (2) Y158-1-C 20 Street Elbow (3/8" - 18 NPTF) (2) Y43-3-S

6 Connector (1) 23902-210 21 Siphon Tube (1) 94512

7 Gauge (0 - 60 p.s.i.) (1) 100090 22 Bolt (1/4" - 20 x 1") (4) Y6-45-T

8 Gauge (0 - 160 p.s.i.) (1) 100091 23 Washer (.281" i.d. x .625" o.d.) (4) 93096

9 Coupling (1/4" - 18 NPT) (1) Y43-42-C 24 Nut (1/4" - 20) (4) Y12-4-S

10 Tee (1/4" - 18 NPTF) (1) 94039 25 Nut (5/16" - 18) (2) Y12-5-S

11 Gauge (0 - 30 p.s.i.) (1) 93769 26 Flange Nut (5/16" - 18) (2) 93886

12 Thumb Screw (3) 94078 27 Nut (1) 94036

13 Tube (12'' long) (1) 628091-1 28 Roll Pin (.094" o.d. x .250" long) (1) Y178-18-S

14 Nut (2) 100022 29 Elbow (1/4" - 18 NPTF) (1) 94044

15 Coupler (1) 23102-200 30 Ground Kit Assembly (not shown) (1) 66885-1

fTube is available inbulk quantities only.

GENERAL DESCRIPTION (CONTINUED)

Consult your sales representative for the proper low pressure gun and

other accessories which will best match the application.

The drum cover features a mount for locating an agitator (pn 651100),

which is available separately.

Theory of operation:

HVLP (High Volume, Low Pressure) is a spray process which uses a

high volume of air(15 - 22 c.f.m.) at a low pressure(10 p.s.i. or less) to

atomize the material, producing both high transfer efficiency (the total

percent of material that actually stays on the intended surface) and a

quality finish.Theair capofthe HVLP gun injects airintothe fluid after it

passes through the orifice restriction. The low velocity of the material

being sprayed minimizes the over-spray and bounce-back that is asĆ

sociated with conventional air spray.

OPERATING INSTRUCTIONS

WARNING

DO NOT EXCEEDMAXIMUM OPERATING PRESĆ

SUREOF 100 P.S.I.(6.9 BAR)AT 100P.S.I. (6.9 BAR) AIR INLET

PRESSURE.

WARNING READ THE PUMP MANUAL FOR ADDITIONAL

OPERATING AND SAFETY PRECAUTIONS AND OTHER IMĆ

PORTANT INFORMATION.

INITIAL

SETUP PROCEDURE

NOTICE

REFER TO THE INFORMATION INCLUDED WITHTHE LOW PRESĆ

SURE HVLP GUN FOR SYSTEM SETUP INFORMATION. THE SYSĆ

TEM IS INTENDED FOR LOW PRESSURE APPLICATION ONLY.

• Attach air supply hose, gun and low pressure material hose.

• Install the connector to the air supply hose.

• Attach the ground wire to a suitable ground.

• The gun air supply hose must be 5/16'' i.d. minimum.

• Keep containers covered to prevent contamination.

• When using an agitator, install a ``T'' at the air inlet or use a sepĆ

arate air supply source.

Nominal system settings:

• Pump Outlet Material Pressure - 15 p.s.i. maximum.

• Spray Gun Air Pressure - 60 p.s.i. maximum. Note: At 30 p.s.i.

nominal setting it will deliver approximately 8 p.s.i. at the air cap

when using 5/16" i.d. x 15' long air hose.

• Set air pressure to the pump at approximately 2x (two times) the

operating material pressure.

For example: If 15 p.s.i. material pressure is required, adjust the

pump air regulator/gauge pressure to approximately 30 p.s.i.

Use the material pressure regulator to adjust. Control the spray

gun air volume using the air regulator.

START–UP

1. Turn the knob on the air regulator counterclockwise to zero p.s.i.

2. Place pump and cover (with gun and hose attached) onto the conĆ

tainer of material.

3. Theoperating pressureshould be set atthe lowest needed toatomĆ

ize anddeliver the paint. Start with the gun material pressureabout

the same asthe airsupply and adjustup ordown toset the pattern.

4. Start the pump to cycleby turning the air regulator knob clockwise.

The pump will cycle several strokes until pressure is built up in the

system, at which time it will stop. Check for any loose fittings or

leakage.