Page 2 of 2 650311-X & 650312-X (en)

PN 97999-1588

GENERAL DESCRIPTION

Model 65031X-X Series two-ball, double acting pumps are intended

to be used primarily for oil transfer and delivery systems. It is best to

use this pump with low -- medium viscosity uids. It uses Stainless

steel and other materialswhich make it compatible with most petro-

leum based lubrication products. The two-ball design provides bet-

ter priming of the lower foot valve. Double acting pumpswill deliver

material on both the up and down stroke.

NOTE: If this pump was purchased separately (not part of a system),

consult your sales representative for compatible dispensing acces-

sories which will best match the application. All accessories must be

able to withstand the maximum pressure developed by the pump.

WARNING

HAZARDOUS PRESSURE. Do not exceed maxi-

mum operating pressure of 343 p.s.i. (23.6 bar) at 150 p.s.i.

(10.3 bar) inlet hydraulic pressure.

Pump Ratio X = Maximum Pump

Inlet Pressure to Pump Motor Fluid Pressure

Pump ratio is an expression of the relationship between the pump motor area

and the lower pump end area. EXAMPLE: When 150 p.s.i. (10.3 bar) inlet pressure

is supplied to the motor of a 4:1 ratio pump, it will develop a maximum of 600

p.s.i. (41.4 bar) uid pressure (at no ow) - as the uid control is opened, the ow

rate will increase as the motor cycle rate increases to keep up with the demand.

WARNING

Refer to general information sheet for additional

safety precautions and important information.

NOTICE: Thermal expansion can occur when the uid in the mate-

rial lines is exposed to elevated temperatures. Example: Material

lines located in a non-insulated roof area can warm due to sunlight.

Install a pressure relief valve in the pumping system.

Replacement warning label (pn 94520) is available upon request.

TROUBLE SHOOTING

Pump problems can occur in either the Air Motor Section or the

Lower Pump End Section. Use these basic guidelines to help deter-

mine which section is affected. Be sure to eliminate any possible

non-pump problems before suspecting pump malfunction.

Pump will not cycle.

No pressure to the motor. See motor manual.

Damaged motor. Service motor.

No material at the outlet (pump continually cycles).

Check the material supply, disconnect or shut o the air supply

and replenish the material, reconnect.

Material on one stroke only (fast downstroke).

The lower check may not be seating in the foot valve (see lower pump

disassembly). Remove the check from the foot valve, clean and in-

spect the valve seat area. If check or foot valve are damaged, replace.

Material on one stroke only (fast upstroke).

The middle packings may be worn (see lower pump disassem-

bly). Replace the seals as necessary.

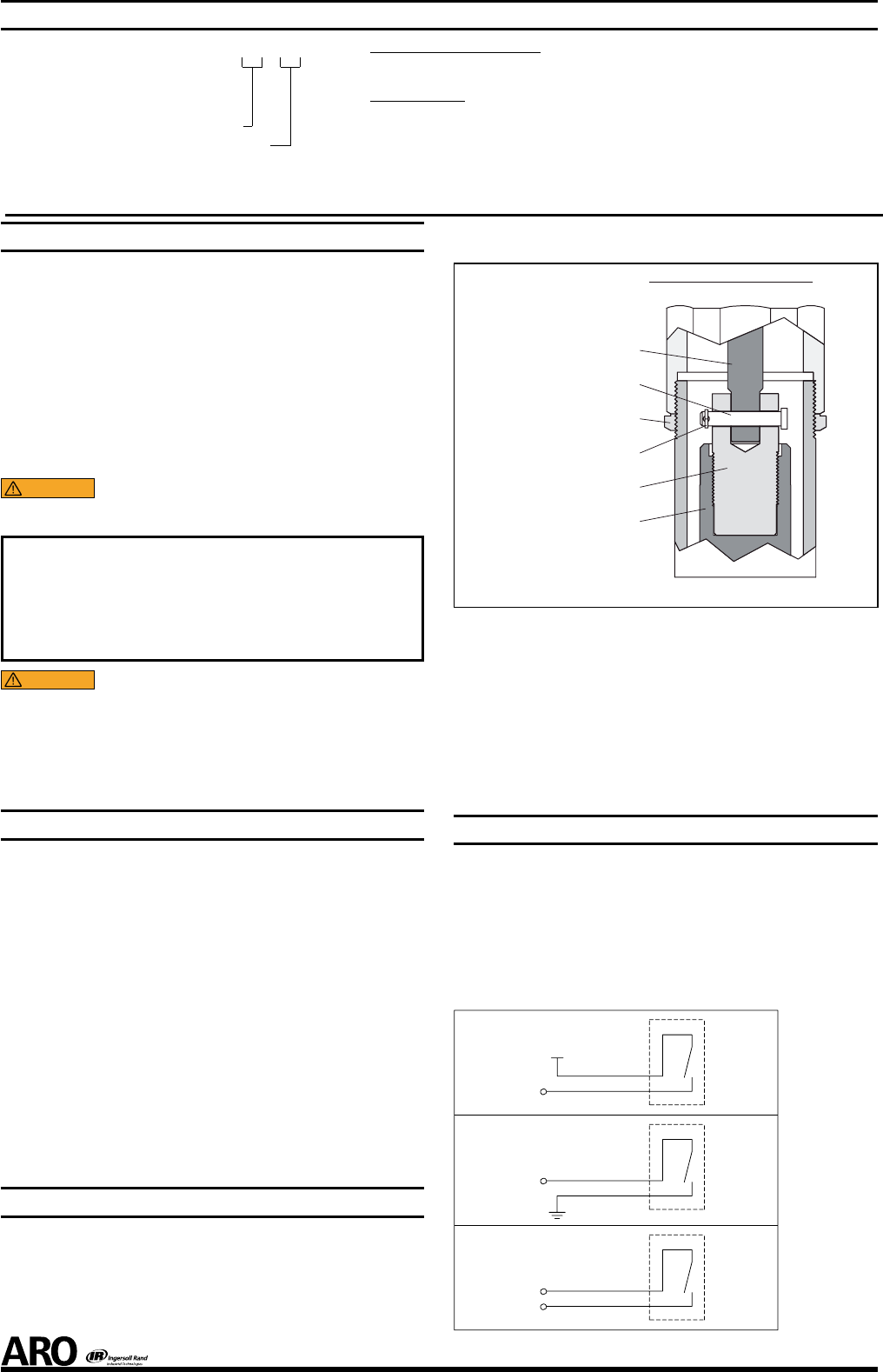

PUMP CONNECTION - UPPER / LOWER

NOTE: All threads are right hand.

Loosen (90606) lock nut and unscrew the entire pump from

the air motor. This will expose (94445) adapter (see gure 2).

Unscrew (94445) adapter to remove pump assembly from the

air motor.

1.

2.

Remove the (Y15-21) cotter pin and (94048) clevis pin to

remove (94445) adapter.

Pump Motor Piston Rod

PUMP CONNECTION DETAIL

Figure 2

Y15-21 Cotter Pin

Lower Pump Plunger

90606 Lock Nut (ref.)

94048 Clevis Pin

94445 Adapter

REASSEMBLY

Assemble (94445) adapter to the air motor rod, aligning the

through holes.

Assemble (94048) clevis pin through hole, securing adapter.

Assemble (Y15-21) cotter pin through the hole in the clevis pin.

Apply Loctite® 242 to threads of (94445) adapter and screw

(94445) adapter into (90615-X) plunger.

Screw the lower pump assembly to the air motor.

Screw (90606) lock nut against the air motor base and tighten

to 50 - 60 ft. lbs (67.8 - 81.3 Nm).

OPERATION - SENSOR

Maximum Operating Voltage - 200VDC.

Switching Current -0.5 Amps.

Once the kit is installed in the pump, it may be interfaced with a

control device in the following ways:

As a SOURCING switch (see gure 3) for use with PLC’s.

As a SINKING switch (see gure 4) for use with PLC’s.

As a closed contact switch (see gure 5) for use with meters.

INPUT

INPUT

INPUTS

Figure 3

Figure 4

Figure 5

+V

Sourcing Switch

Sinking Switch

Closed ContactSwitch

3.

1.

2.

3.

4.

5.

6.

PUMP OPTION DESCRIPTION CHART

65031- X - X

Container Suitability

Description

CONTAINER SUITABILITY

1 - Universal (stub)

2 - 55 Gallon

DESCRIPTION

- PTFE packing (upper and lower)/ Plain Rod & Tube

4 - UHMW-PE packing(upper and lower) / Plain Rod & Tube

5 - PTFE packing (upper and lower) / Ceramic Coated Rod & Tube

6 - UHMW-PE packing(upper and lower) / Ceramic Coated Rod & Tube

7 - Viton packing(upper)/UHMW-PE packing (lower)/ Ceramic Coated Rod & Tube

8 - Viton packing(upper)/PTFE packing (lower)/ Plain Rod & Tube

9 - Viton packing(upper)/UHMW-PE packing (lower)/ Plain Rod & Tube