ECR International

Hyundai Ductless Split System13

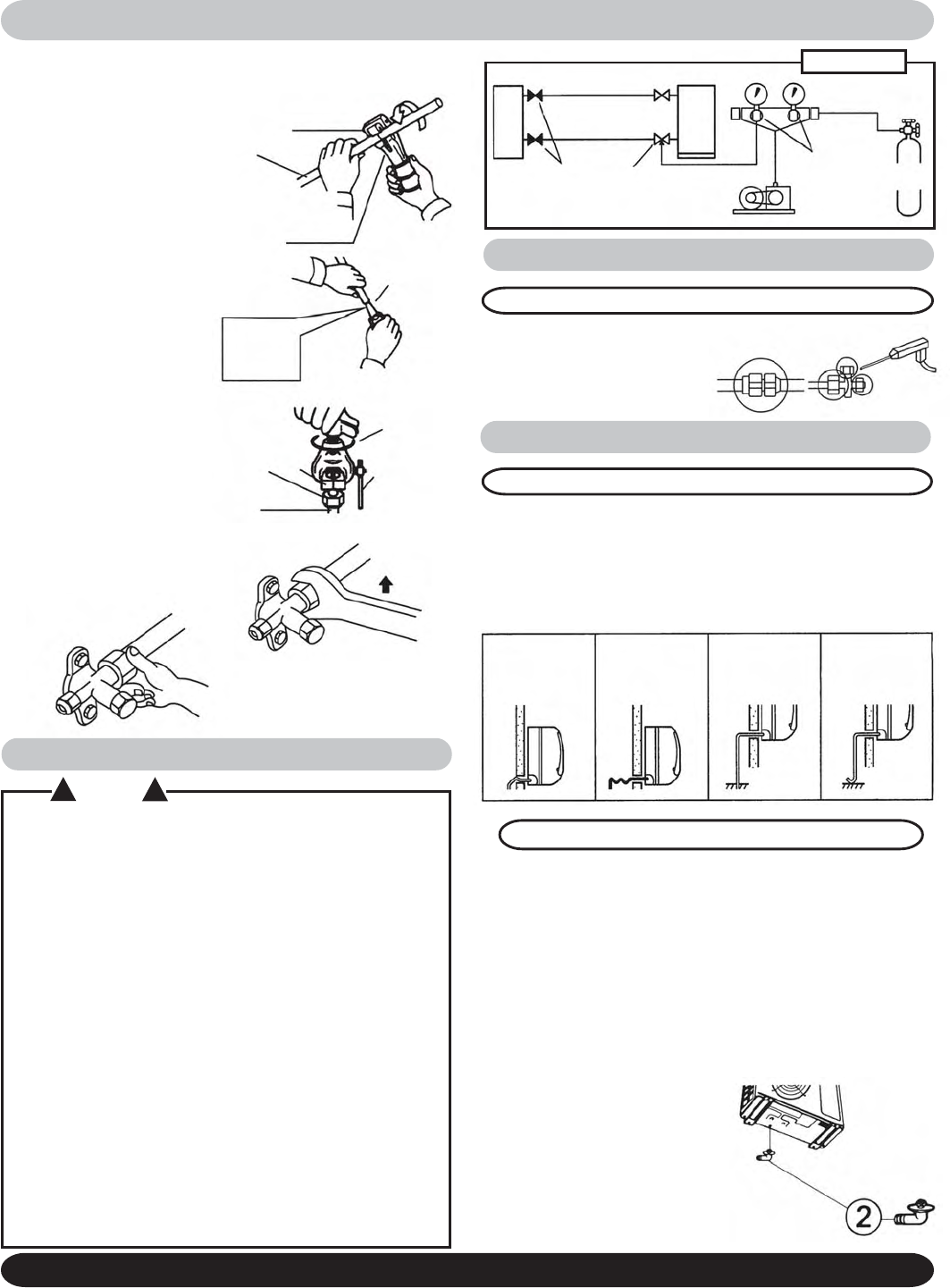

1. Cutting and flaring of

tubing:

A. Cut the tubing on its

straight part with the

pipe cutter.

B. Remove burrs from cut

edges of pipes, which

may cause a gas leak.

C. Flaring of the pipe is

done with the flaring

tool.

NOTE: Do not forget to in-

stall the flare nut before

flaring

2. Pre-Connecting:

Screw the tubing turning

3 to 5 times until hand

tight.

3. Fastening:

Fasten the connection.

• Apply refrigeration oil to

the flare surface to pre-

vent gas leakage.

Leak Test

Leak Check

Check the joints with a gas

leak detector or soapy water for

refrigerant leaks. If a leak is

found, repair and recheck.

Drainage

Indoor Unit

After the indoor unit(s) have been installed, make sure that

condensed water is properly drained. (If this is neglected,

the unit(s) may become flooded.)

Special care should be given to the following details:

Outdoor Unit (Heat Pump Only)

NOTE: Allow clearance for drainage of water or condensate.

For outdoor condensation:

• The outdoor unit has drain outlets on the base to drain

condensation to the outside.

• To drain condensation by hose (5/8” hose) with the drain

socket, connect the socket to the center of the base and

cover all other outlets with base caps.

• Install the outdoor unit on a flat level surface and make

sure condensation drains smoothly.

• In cold areas, condensation

and defrost water can freeze,

therefore do not use the drain

outlet caps during the cold sea-

son.

• Electrical connection should

only be made by a qualified pro-

fessional.

• See the “Determination of Installing Position”.

Connecting of Tubing

INSTALLING OF THE OUTDOOR UNIT

1) Remove the cap from the service port on the suction line service

valve.

2) Connect the suction side of the refrigerant gauge manifold to

the Suction Line service valve. Connect the center hose of the

refrigerant manifold gauge to the micron gauge. Connect the

other side of the micron gauge to the vacuum pump. (Diagram 1)

3) Open the suction side of the refrigerant manifold set and turn

the vacuum pump on. NOTE: Evacuate the system down to

400 microns.

4) When the system pulls down to 400 microns turn the vacuum

pump off. Observe the micron gauge: if the system has a leak

the gauge will detect it. If there is a leak, find it, repair it, and

repeat steps 3 and 4.

5) Close the refrigerant gauge manifold valve and disconnect the

vacuum pump from the system.

6) Remove the Suction and Liquid line Service Valve Caps from the

valves.

7) Using an Allen wrench, open the Liquid Line Service Valve until

the valve is in the fully open position. Next do the same for the

Suction Line Service valve. NOTE: Be careful as not to

completely remove the valve core from the valve. This

will result in the release of refrigerant from the system

into the atmosphere!

8) Re-install the caps on both service valves. This completes the

charging of the system.

! CAUTION !

Cut pipe by rotating the

pipe cutter

Pipe

Turn the handle

Clockwise while

pushing it against

the pipe

Pipe cutter

knife

Yoke

Do not dam-

age the in-

side of the

pipe.

Bar

Flare nut

Fix pipe

turning clamp

handle.

Pipe

• Drain hose must

slope downward

to the outdoor

side.

• Do not use a trap

or kink.

• Never put the

end of the drain

hose into the

water.

• Do not tilt up-

ward.

Flare nut Flare valve

Manifold gauges

Charge

cylinder

Discharge

Suction

Vacuum pump

INDOOR

UNIT

OUTDOOR

UNIT

Diagram 1

Air Purge and Charging

(SINGLE ZONE SYSTEM SHOWN)