D

13

Clearing blockages

Disconnect cleaner from electrical

outlet.

Low suction or pick up may be due to a

blockage in the system. Refer to the fol-

lowing steps to check for blockages

continuing with each step until the

blockage is found:

Turn cleaner OFF and disconnect from

electrical outlet.

1. Check fullness of dirt cup and filter

assembly; empty cup and clean filters if

needed.

Service

To obtain approved HOOVER service

and genuine HOOVER parts, locate

the nearest Hoover Factory Service

Center or Authorized Hoover

Warranty Service Dealer (Depot) by:

•checking the Yellow Pages under

“Vacuum Cleaners - Household” OR -

•checking the list of Factory Service

Centers provided with this cleaner

OR -

•checking the Service section of The

Hoover Company on-line at

www.hoover.com OR -

•calling 1-800-944-9200 for an

automated referral of authorized

service outlet locations (U.S. only).

Do not send your cleaner to The Hoover

Company in North Canton for service,

this will only result in delay.

If further assistance is needed, contact

The Hoover Company Consumer

Response Center, North Canton,

Ohio 44720, Phone: 330-499-9499.

In Canada, contact Hoover Canada,

Burlington, Ontario L7R 4A8,

Phone: 1-800-263-6376.

Always identify your cleaner by the

complete model number when

requesting information or ordering parts.

(The model number appears on the

bottom of the cleaner.)

4. If you have a

Hoover cleaning

performance

This Hoover Cleaning Performance Sys-

tem is for comparing the relative pro-

gressive performance of Hoover

uprights only and not for comparison

with any other brands. The majority of

this rating is based upon the ASTM

International Carpet Cleaning Effective-

ness Test (ASTM Test F608). Other per-

formance factors include Hose Power

(ASTM Test F558), Surface Litter Clean-

ing, Hard Floor Cleaning, Edge Clean-

ing, Cleaning Width, and Air Filtration.

4-2

A

C

B

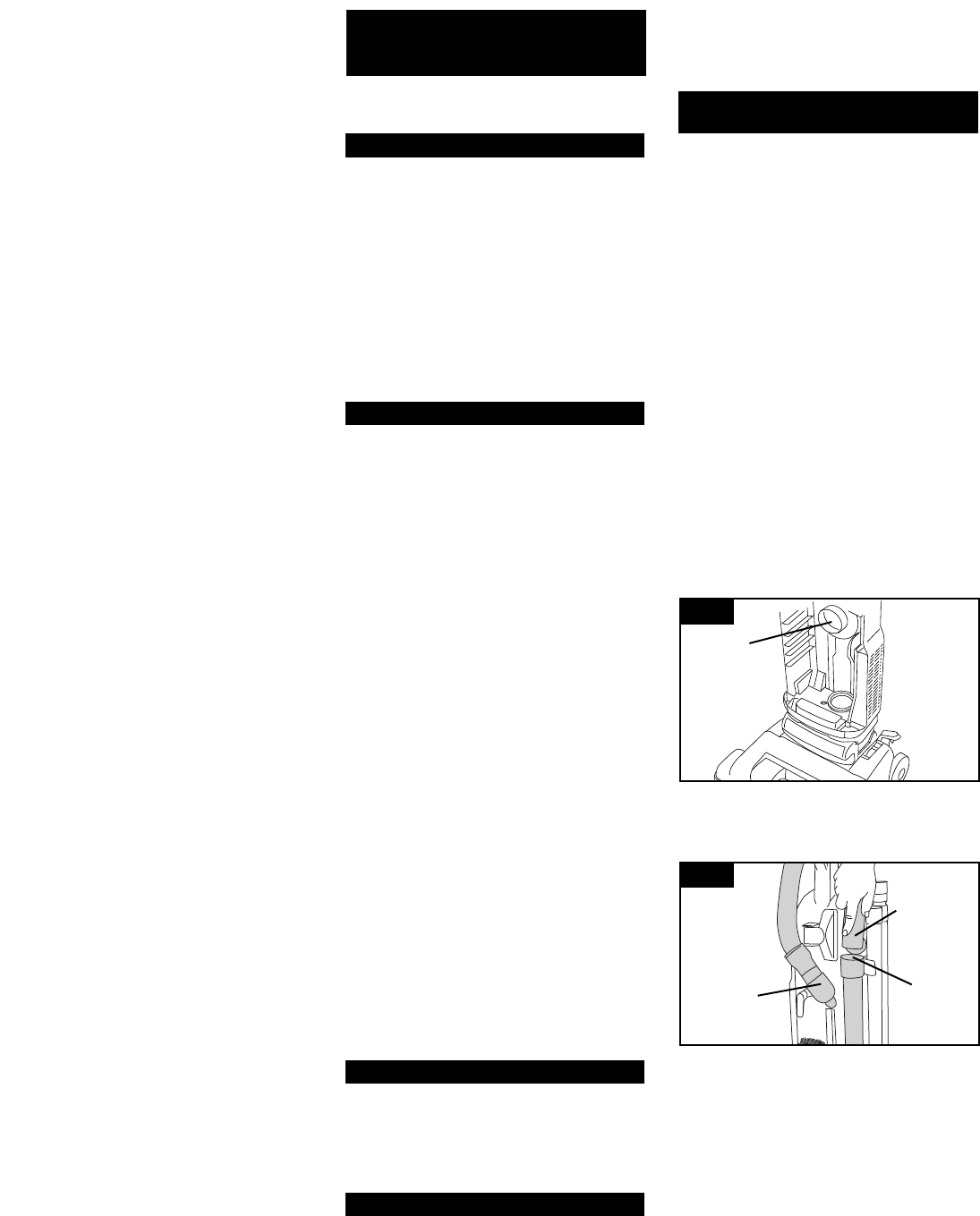

Check airflow path

4. Plug cleaner in and turn ON. Check

for suction at end of hose (B).

a. If there is suction, continue with

step 5.

b. If there is no suction, check for

blockage in hose and dirt tube as

follows:

1) DIsconnect hose from dirt duct

(D) by reversing procedure for

“Attach hose” (Fig. 1-8 and 1-9).

2) Clear out hose.

4-1

Check dirt duct

2. Remove dirt cup, look in duct (A).

3. Clear blockage from dirt duct.

4. If you have a

problem

If a minor problem occurs, it usually can

be solved quite easily when the cause is

found by using the check list below.

Problem: Cleaner won’t run

Possible cause

Possible solution

• Not firmly plugged in

•

Plug unit in firmly

• No voltage in wall plug

•

Check fuse or breaker

• Blown fuse or tripped breaker

•

Replace fuse or reset breaker

• Thermal protector activated

•

Allow cleaner to cool for 30 minutes

(this will reset the thermal protector)

(see pg. 12).

Prob

Problem: Cleaner won’t pick up

Possible cause

Possible solution

• Broken or worn belt

•

Replace belt

• Agitator brush roll worn

•

Replace brush roll

• Dirt cup full

•

Empty cup

• Incorrect carpet height setting

•

Move nozzle control knob to lower

setting

• Blockage in air flow passage

•

Clear blockage

• Main filter clogged

•

Clean main filter by either tapping the

side of the dirt cup or removing the filter

as described in the “Filter assembly”

section

• Pre-filter clogged

•

Clean pre-filter as described in “Filter

assembly” section

• Dirt cup not properly installed

•

Position dirt cup properly and snap in

place (Fig. 3-4)

• Dirt cup lid not positioned properly

or missing

•

Ensure that dirt cup lid is properly

positioned

• Filter assembly not installed

properly

•

Ensure that pre-filter assembly and

main filter are positioned properly (Figs.

3-9 to 3-10)

Problem: Cleaner hard to push

Possible cause

Possible solution

•

Incorrect carpet height setting

•

Move nozzle control knob to a

higher setting

Problem: Cleaning tools won’t pick up

Possible cause

Possible solution

•

Dirt cup not properly installed

•

Position dirt cup properly and snap in

place (Fig. 3-4)

• Blockage in hose

•

Clear blockage

Problem: Visible dirt leaking through

final filter

Possible cause

Possible solution

•

Filter assembly not installed

properly

•

Ensure that pre-filter assembly and

main filter are positioned properly