3

4

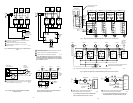

MOUNTING

The valve can be mounted in any position

on a vertical line. See Fig. 2. If the valve is

mounted horizontally; the actuator must be

even with or above the center line of the

piping. Make sure to leave enough room

above the actuator to remove the cover for

servicing.

Mount the valve directly in the tube or pipe

after the coil.

Make sure that the flow

through the valve is in the direction

indicated by the arrow stamped on the

valve body.

Sweat Copper Models

1. Use new, properly reamed pipe, free

from dents or corrosion.

2. Place the valve on the pipe. Set the

manual opening lever to MAN. OPEN

position before applying heat. This

protects the plug inside the valve by

removing it from the seat.

3. Sweat the joints, keeping the outer

surface free from solder. DO NOT use

silver solder because of the high

melting temperature required.

TO INSTALL A COMPLETE VALVE (V8043):

1. Disconnect power supply before

connecting wiring to prevent electrical

shock or equipment damage.

2. Install valve into pipe on the return side

of the coil. (See Mounting Section.)

3. Make wiring connections to valve. (Refer

to Wiring section for proper instructions.)

4. Inspect the valve installation to ensure

that all connections and adjustments

have been correctly made. Adjust the

M10162

VERTICAL

PIPING

HORIZONTIAL

PIPING

Fig. 2 - Mounting Positions

thermostat or controller connected to the

valve so that the valve runs through its

cycle. Make sure the valve runs

smoothly and positively from closed to

open to closed again. (See Operation

and Checkout Sections.)

TO REMOVE THE ACTUATOR FROM THE

VALVE BODY (See Fig. 3)

NOTE!

It is not necessary to drain the hydronic

system if the valve body assembly remains in

the pipe line.

1. Switch power supply OFF. Disconnect

electrical leads carefully, noting the

position and colour of each lead.

2. Place the manual lever in the MAN.

OPEN position.

3. Remove actuator by fully depressing

spring release button and lift it straight

off of the body.

3. LIFT ACTUATOR

STRAIGHT UP

1. PLACE MANUAL

LEVER IN OPEN

POSITION

2. DEPRESS

LOCKING

BUTTON

AUTO OPEN

Fig. 3 - Removing Actuator from Valve Body

TO INSTALL REPLACEMENT ACTUATOR

ON THE VALVE BODY

1.

Align the parallel flat surfaces in

double-D shaft of valve body with

notch in side of body (i.e. 90

°

to water

flow.) See Fig. 4.

This makes actuator

attachment easier.

2. Wiring connections may be made either

before or after actuator installed on

valve body.

3.

Place the manual lever on the

actuator in the MAN. OPEN position.

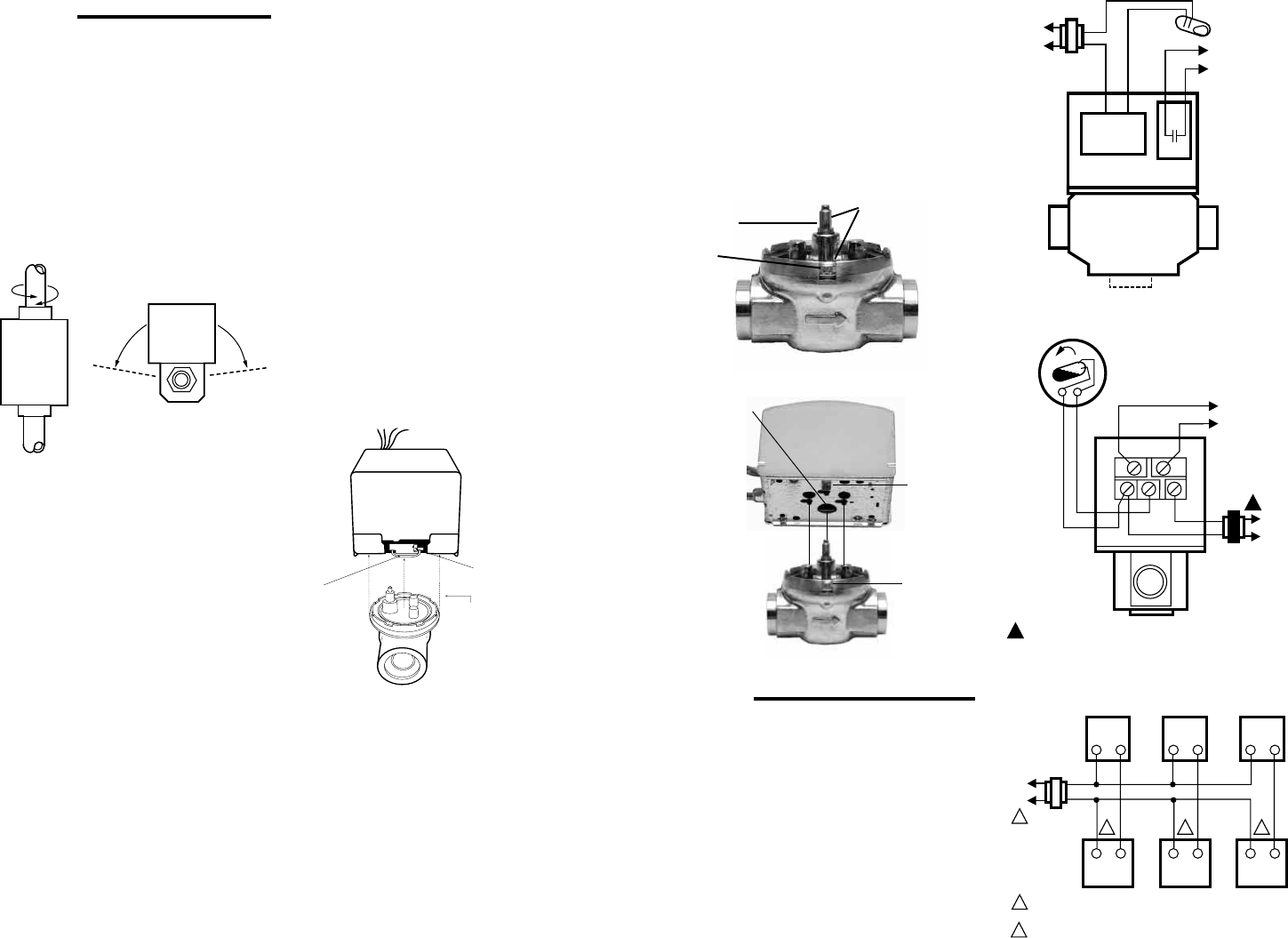

WIRING

Disconnect the power supply before

connecting wiring to prevent electrical shock

or equipment damage.

All wiring must comply with local codes and

ordinances. Connections to the individual

valves are shown in Fig. 6 and 7. See Fig. 8

through 14 for typical hookups.

If replacing a Taco, Dole, Flair or White

Rodgers 3-wire valve with a 2-wire V8043E or

F, see Fig. 15 through 27. Check that the

pressure rating of the new valve is

appropriate for the application.

R

L1

(HOT)

L2

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

END SWITCH

TO CIRCULATOR

OR ANOTHER

VALVE

TH

TR

24V

TRANSFORMER

THERMOSTAT

(TYPICALLY T87F)

TH TR

M5952

AUXILIARY

SWITCH

MOTOR

YELLOW

LEADS

TO CIRCULATOR

OR ANOTHER VALVE

RED LEADS

THERMOSTAT

(TYPICALLY T87F)TO

LINE

M5953

Fig. 6 - Typical wiring for V8043E, V8044E.

Fig. 7 - Typical wiring for V8043F.

L1

(HOT)

L2

1

1

2

2

2 2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

CONNECT V8043A BLACK LEADWIRE TO THERMOSTAT.

T822 T822 T822

V8043A V8043A V8043A

M10168

Fig. 8 - T822 Thermostat, V8043A valve hookup.

4. Line up motor coupling to the parallel flat

surfaces in double-D shaft of body and fit

the actuator onto the valve body,

ensuring that the shaft seats correctly.

(See Fig. 5)

5. Snap actuator onto body by pressing

down.

6.The manual lever may be released

manually, but it is also automatically

released when the valve is operated

electrically.

Fig. 5 - Installing Actuator

Notch Tab

Notch

Actuator

Coupling

Fig. 4 - Shaft Position

Double-D

Shaft

Parallel flat surfaces

align with Notch on

side of valve body

Notch