S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

11 69-2076—01

“SP_” Setpoint.

“Df_” Setpoint Differential (select models).

“°F_” Degrees Fahrenheit

Then press the UP or DOWN button until the parameter

has reached the desired value. After 60 seconds without

any button inputs, the control will automatically return to

the READ mode.

Display

In the RUN mode, status items and parameters are

viewable. For example, to display setpoint, the control will

flash “sp” (setpoint) followed by the temperature (i.e.,

135), followed by °F or °C.

To read settings, press and release the I key to find the

parameter of interest. For example, press and release I

until setpoint (sp) is displayed, followed by a three-digit

number, i.e., 220, followed by °F or °C. Pressing the I

button again will display the (S1T) Sensor 1 Temperature

followed by a three-digit number and the corresponding

degree designator. See Display Readout, Fig. 6.

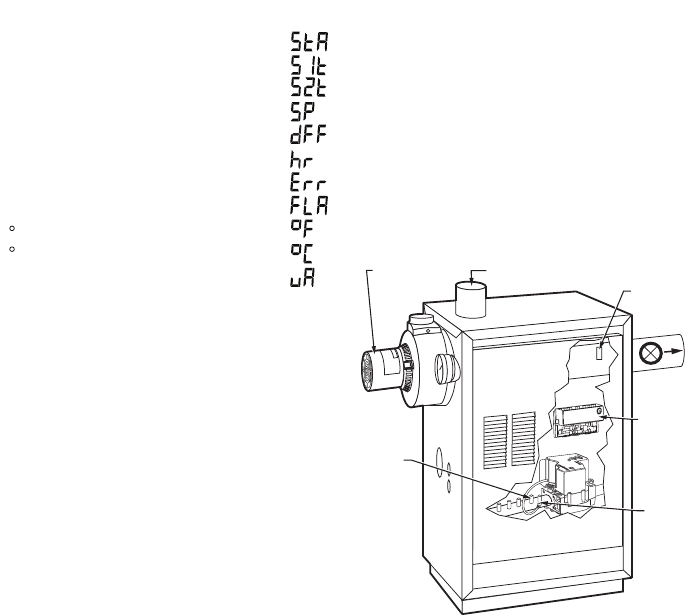

Fig. 6. Display readout definitions.

Boiler Temperature Controller

When the water temperature reaches setpoint, the

controller ends the heating cycle. When the water

temperature drops below the setpoint minus the

differential, the control restarts a heat cycle to re-heat the

tank of water.

If the water temperature exceeds the max allowed

temperature, the control enters a manual reset lockout

state. For models that have reset capability, press any on-

board button (when present), cycle power, or use the

remote display to reset.

CHECKOUT

Put the system into operation and observe operation

through at least one complete cycle to make sure that the

controller operates properly. See Troubleshooting section

to assist in determining system operation.

LOCATION AND MOUNTING

Sensing Bulb(s)

The water heater manufacturer usually provides a tapping

for the sensing bulb at a point where average water

temperature can be measured. Some water heaters use

two (2) sensors, one limit rated near the center or bottom

of the tank, the other non-limit rated near the top. See Fig.

7. Follow the heater manufacturer instructions.

The sensing bulb can be installed in an immersion well.

Wells and fittings must be ordered separately. See 68-

0040.

When an immersion well is used, the sensor should fit

snugly and should touch the bottom of the well for best

temperature response. Use heat-conductive compound

(Honeywell part no. 107408) to fill the space between the

bulb and the well to improve heat transfer characteristics

(optional). Make sure the sensor is held firmly in the well.

Remote Display

For units that use a remote display, refer to I&I sheet for

SD7000A.

WIRING

IMPORTANT:

For maximum trouble free operation, run the

sensor leadwires separately from any other cur-

rent-carrying wires.

All wiring must comply with local codes and ordinances.

Disconnect power supply before beginning wiring.

Connect according to water heater manufacturer

instructions.

Fig. 7. Typical location of limit function sensor and

control module.

Setpoint

Text Description

Di

sp

l

ay

Shows

sp

Current State

Sensor 1 Temperature

Sensor 2 Temperature*

sta

s1t

s2t

Setpoint Differentialdff

Heat Request Statushr

Flame Currentfla

Degrees Fahrenheit F

Error Codeerr

Micro Amps

uA

M24052

Degrees Celsius C

M27076

PILOT

MAIN

BURNER

INLET

INTEGRATED

BOILER

CONTROL

INDUCER

MOTOR

(OPTIONAL)

SUPPLY

PUMP

LIMIT

SENSOR