R8182D,E,F,H,J COMBINATION PROTECTORELAY™ AND HYDRONIC HEATING CONTROLS

7 68-0105—2

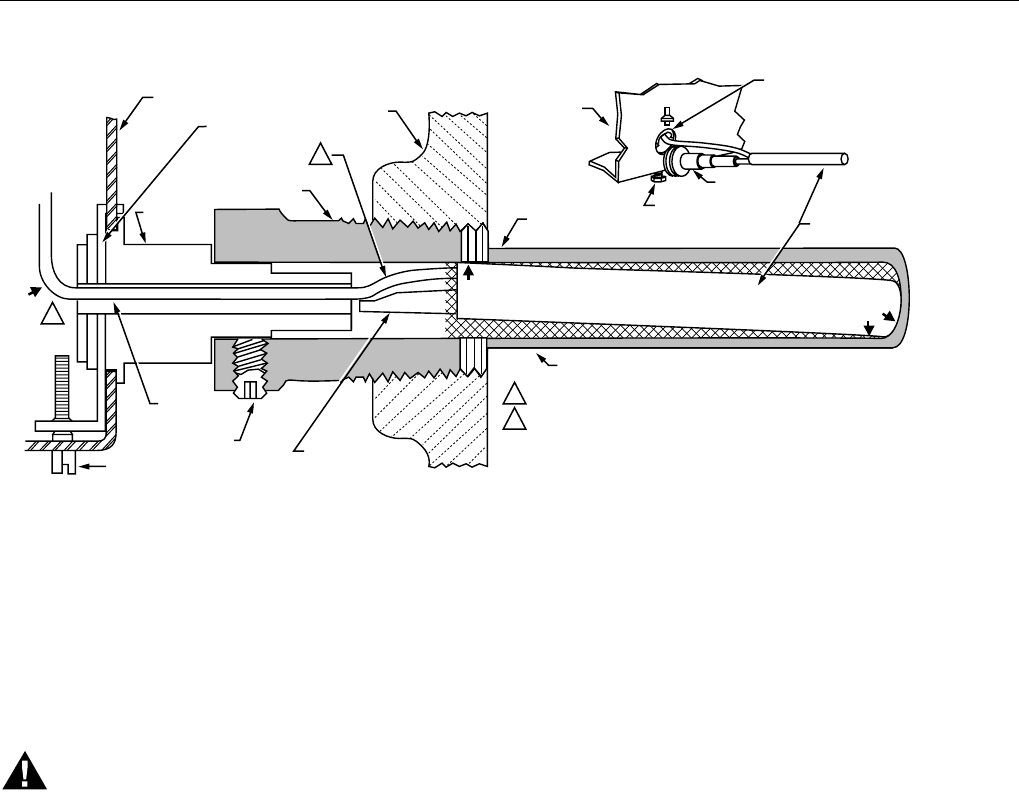

Fig. 9. Positioning the sensing bulb in the immersion well.

WIRING

IMPORTANT

Use Underwriters Laboratories Inc. listed connectors

when making external circuit connections to the

orange and white line voltage burner and ignition

leadwires of the R8182H,J.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before wiring to prevent

electrical shock or equipment damage.

All wiring must comply with local codes, regulations, and

ordinances.

IMPORTANT

Terminals on the R8182 are approved for copper

wire only.

Follow the wiring instructions furnished by the appliance

manufacturer, if available, or refer to Fig. 11 through 17. For

wiring multiple zoning systems, refer to Fig. 16 and 17.

The R8182 is equipped with special wiring terminals. Wires

can be wrapped around the terminal screw or inserted from

the side.

Method 1

1. Strip 7/16 in. of insulation from the wire end.

2. Wrap the wire 3/4 of the distance around the screw as

shown in method 1.

3. Using a standard, flat-headed screwdriver, tighten the

screw until the wipe is snugly in contact with the screw

and contact plate.

4. Tighten the screw pin an additional one-half turn.

Method 2

1. Strip 5/16 in. of insulation from the wire end.

2. Insert wire beneath the screw as shown in method 2.

3. Using a standard, flat-heat screwdriver, tighten the

screw until the wire is snugly in contact with the screw

and contact plate.

4. Tighten the screw an additional one-half turn.

NOTE: Do not use a push-type ratchet screwdriver.

The TRADELINE® R8182D,H can be converted to replace an

R8182B,C,E,F or a White Rodgers 6C92-2 or 6C92-3. When

replacing a White Rodgers model, the immersion well must

also be replaced. Refer to Fig. 10 for Aquastat® limit

connections necessary for each R8182D conversion.

To release the wires from the R8182, insert a screwdriver into

the rectangular hole adjacent to the wire, push inward to

release the locking-grip on the wire, and pull the wire out of

the terminal hole.

To reinsert the wire into a new terminal hole, simply push the

wire into the new slot.

CONTROLLER

CASE

IMMERSION

WELL CLAMP

ADAPTER

IMMERSION

WELL SPUD

BOILER

OLD IMMERSION

WELL ASSEMBLY

BACK OF

CONTROLLER

CASE

IMMERSION

WELL CLAMP

SCREW

ADAPTER

SENSING

BULB

HEAT-CONDUCTIVE COMPOUND

SETSCREW

CAPILLARY

TUBE

(

C)

IMMERSION

WELL CLAMP

IMMERSION

WELL CLAMP SCREW

SHORT TUBE

FITS IN CENTRAL

RECESS OF ADAPTER

BEND THE CAPILLARY TUBE TO HOLD THE SENSING BULB IN GOOD

THERMAL CONTACT WITH THE IMMERSION WELL AT POINTS (A) AND (B).

ASSURE THAT CAPILLARY TUBE FITS FREELY IN THE ADAPTER SO THE

TENSION OF THE CAPILLARY TUBE AT POINT (C) HOLDS THE SENSING

BULB IN GOOD THERMAL CONTACT WITH THE IMMERSION WELL AT POINT (D

).

M883

0

1

1

2

2

(D)

(B)

(A)