Q179A,B GAS PILOT BURNER ASSEMBLIES

5 60-2032-05

WIRING

CAUTION

Disconnect power supply to prevent electrical

shock and equipment damage. More than one

disconnect may be involved. Wiring must conform

to local codes and ordinances.

Rajah connectors are furnished for making connections to the

ignition and flame electrodes. The ignition electrode (A models

only) takes a receptacle connector. The flame electrode (both

A and B models) takes a plug connector and has a snap-action

spring terminal.

Use high tension wire, of a type found acceptable by a

nationally recognized testing agency, for the wiring to the

ignition electrode (Q179A). High tension wires should be rated

electrically equivalent to type GTO-10 and should have

temperature and humidity characteristics adequate for the

application. If the ignition lead is exposed to temperatures

above 125°F (52°C), use Honeywell R1061012 Ignition Cable

rated at 350°F (177°C) or equivalent. For ignition installations

in a contaminated environment, use Honeywell 32004766-003

High Tension Cable rated at 482°F (250°C) or equivalent.

For wiring between the F terminal of the relay and the flame

electrode, use wire with moisture-resistant insulation. Number

14 single-conductor TW wire is adequate; however, those

portions of the lead wire exposed to temperatures over 125°F

(52°C) should also be heat resistant. For both heat and

moisture-resistant applications, use part no. R1298020 Flame

Rod Lead wire rated at 400°F (204°C) continuous duty or

equivalent.

Run a ground wire from the pilot burner to the relay to assure a

continuous, unchanging ground.

For detailed wiring diagrams, see the Instructions packed with

the flame safeguard control.

CHECKOUT

CAUTION

Check to ensure the main valve opens only when

the pilot flame is strong enough to ignite the main

burner. Perform the pilot turn-down test as

described in the Honeywell Flame Safeguard

Control instructions.

The proper pilot burner orifice must be selected for the gas

being used (natural, LP gas) so that the pilot burns with a

medium hard flame. This type of flame provides the maximum

flame signal.

The flame safeguard control relay will chatter if excess

secondary air velocity or a severe draft condition causes the

pilot flame to make intermittent contact with the flame electrode

(rod) or grounding bracket.

The performance of the pilot assembly can be determined by

measuring the flame signal developed with the pilot operating.

The flame signal (current/voltage) measurement requires the

use of an appropriate volt-ohmmeter.

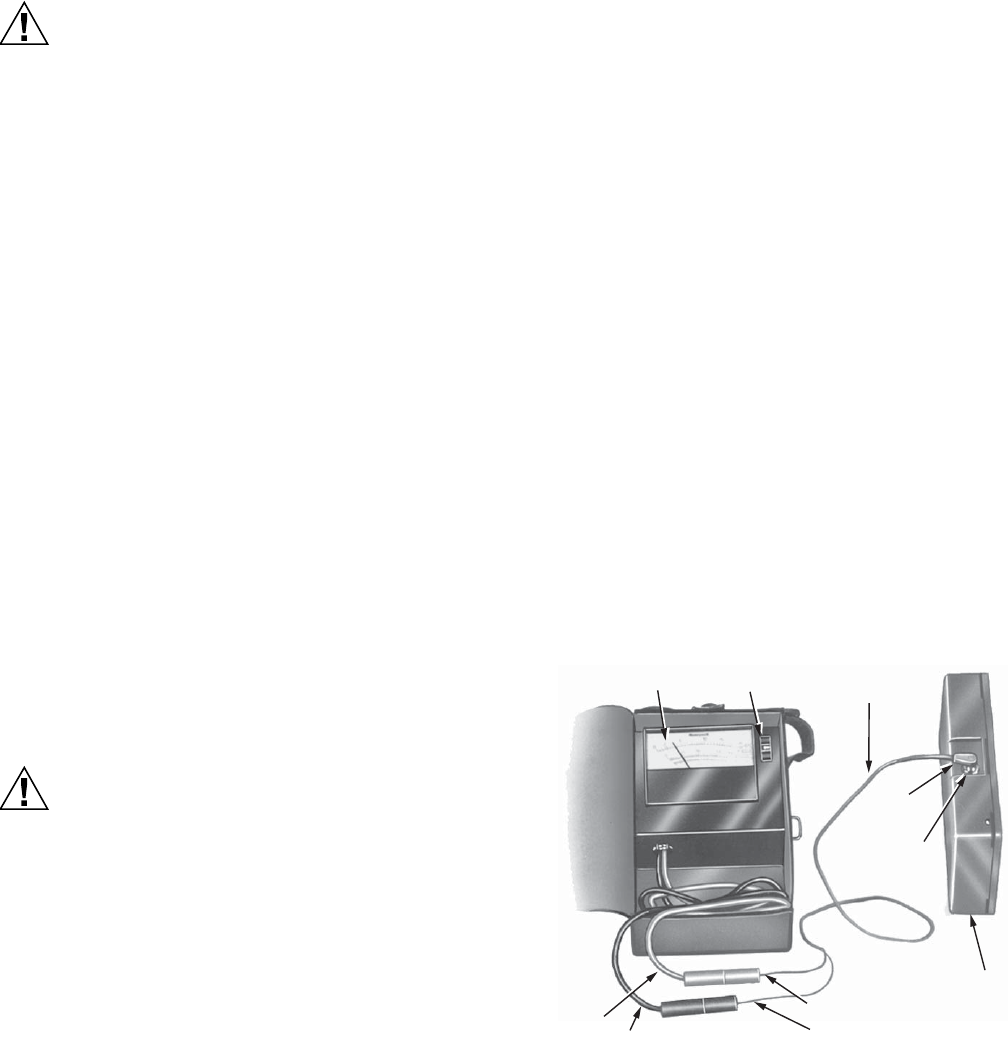

Most existing Honeywell Flame Safeguard Controls

incorporate a flame current jack in the control plug-in amplifier

or in the control itself. The flame current measurement can be

made with a Honeywell W136A Test Meter, which has a 0 to 25

microampere dc scale (see Fig. 4). With the W136A selector

switch positioned to the 0 to 25 microampere scale, connect

the meter leads to the two ends of the meter connector plug,

positive (red, +) to positive, negative (black, -) to negative. The

Meter Connector Plug part no. 196146 is provided with the

W136A Meter. If a W136A Meter or connector plug is not

available, a dc ammeter with a 0 to 25 microampere scale can

be wired in series with the F lead of the flame detector circuit.

A minimum flame current of 2.0 microamperes is considered

acceptable.

The Honeywell 7800 SERIES Flame Safeguard Control flame

signals are measured in dc volts. A one megohm/volt meter is

recommended for 7800 SERIES controls. The flame signal

voltages are measured as illustrated in Fig. 5.

The minimum acceptable flame signal voltage for the 7800

SERIES controls is 1.25 Vdc (maximum expected is 5.0 Vdc).

If the flame signal is less than the minimum acceptable for the

Honeywell Flame Safeguard Control used, adjust the flame

electrode (rod) to increase the flame signal to at least the

minimum acceptable level by loosening the clamp screw and

turning the electrode (rod) slightly to the right or left as

required. After the flame electrode (rod) is adjusted, check the

gap between the ignition electrode and burner tip (Q179A).

The gap must be between 1/16 and 3/32 inch.

Perform the pilot turndown test as described in the Flame

Safeguard Control Instructions to ensure the pilot flame is

adequate to ignite the main burner.

Fig. 4. Measuring microamp flame signal.

W136A VOLT-

OHMMETER

W136A SELECTOR

SWITCH

196146 METER

CONNECTOR

PLUG

PLUG

FLAME SIGNAL

METER JACK

PLUG-IN FLAME

SIGNAL AMPLIFIER

RED CONNECTOR

BLACK CONNECTOR BLACK (–) METER LEAD

RED (+)

METER

LEAD

M6532A