F111 (SERIES 1,2,3) IN CEILING MEDIA AIR CLEANER

7 68-0198-2

14. Connect one wire on air cleaner to power supply wire

with a wire nut following color code used at remote

switch. (White)

15. Connect the ground wire from the remote switch to a

ground stud of the wiring compartment cover.(Green)

16. Fold wires into wiring compartment. Replace wiring

compartment cover.

17. Turn on power to air cleaner at fuse or breaker.

18. Check operation by turning air cleaner at HIGH,

MEDIUM, and LOW. Note

that only the remote switch

will operate the air cleaner.

Lid Assembly

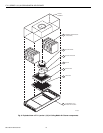

The F111 lid is held in place by two separable hinges and two

spring loaded plungers. To install the spring loaded plungers

on the lid follow these steps:

1. Pull the plunger back and twist a quarter turn to reveal

the wrench flat on the body of the spring loaded plunger

(see Fig 7.)

2. Turn the threaded barrel out of the spring plunger.

3. Insert the threaded barrel through the hole in the lid and

turn the spring loaded plunger onto it.

4. Tighten the assembly with wrenches.

5. Repeat steps 1 through 4 for the second plunger.

Fig. 7. Lid assembly.

Opening/Closing the Lid

To open the lid, pull the spring loaded plungers back to

disengage the plunger. Carefully swing the lid open on the

hinges while supporting the filter and/or adsorbent modules as

required. To close, swing the lid into the closed position and

engage the plungers.

Removing /Replacing the Lid

IMPORTANT

The lid is heavy. Make sure that it is supported

before removing.

To remove the lid, swing it into the open position. Slide safety

catch to off position. Move the lid to the side to disengage the

hinge pins. Reverse the procedure to replace the lid. Make

sure safety catch is in safe position.

OPERATION

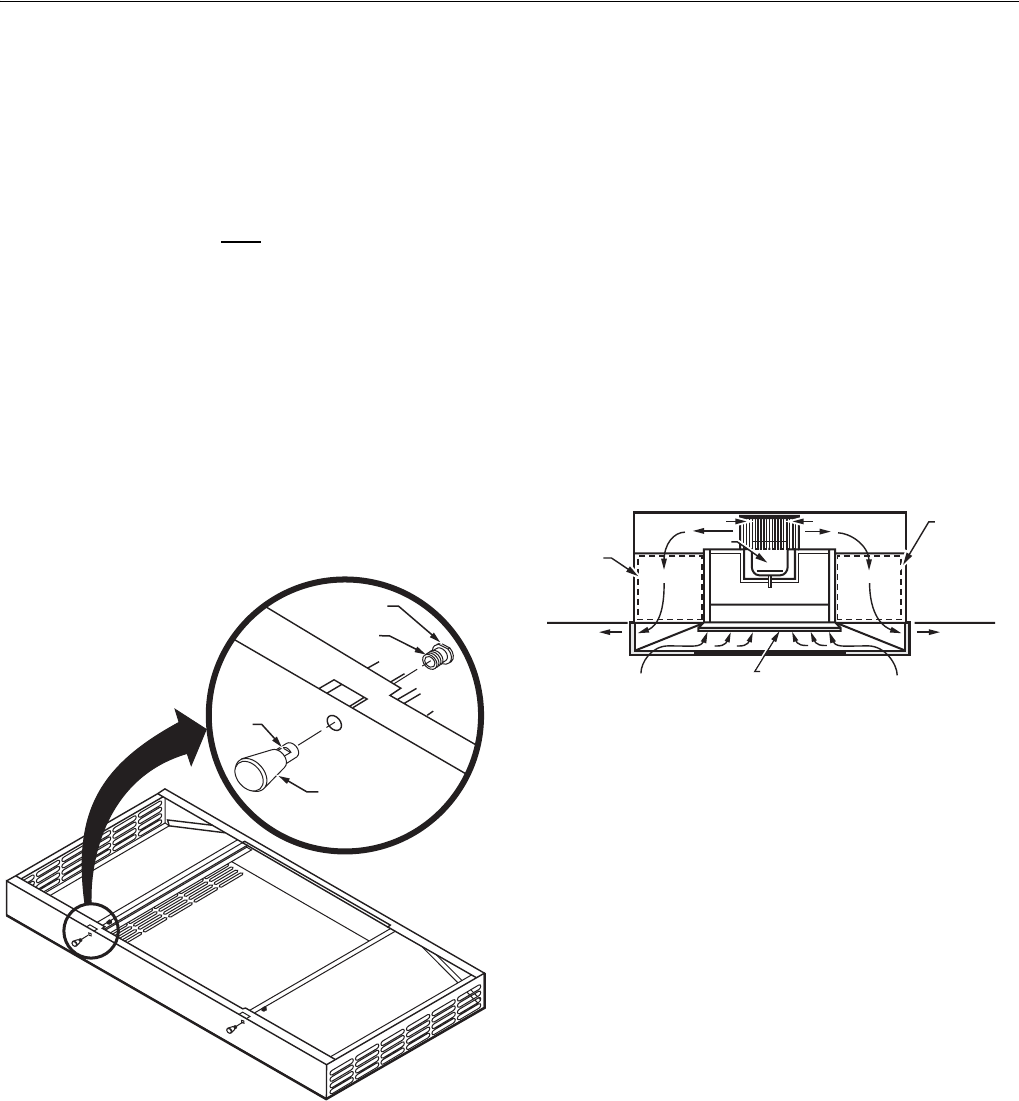

The F111 (series 1,2,3) in Ceiling Media Air Cleaner has been

engineered to improve indoor air quality for commercial and

industrial applications. The filters are the most practical and

effective filtering system for removing atmospheric dust,

pollens, bacteria, viruses, mold spores, smoke, fumes, mists

and aerosols. Refer to Fig. 8.

Fig. 8. F111 (series 1,2,3) air cleaner operation.

The air cleaner is either operating (power on) or off (power

off). There are no other operational options available. Even

when the area is unoccupied, the air cleaner can be operated

continuously to prevent buildup of airborne contaminants.

Operate the air cleaner only when the area is occupied when

specific activities produce contaminants.

The CPZ™ sorbent module has the ability to collect and hold

gas-phase compounds and vapors typically found in

commercial and light industrial facilities. These gases and

vapors frequently appear as odors that, at times, can be

annoying and irritating. The modules become saturated after

collecting 25% to 50% of their weight in gaseous odors. The

quantity of CPZ™ material provides adequate dwell time to

ensure up to 95% collection efficiency in the first pass. This

also provides a long maintenance-free service life.

The minimum recommended air exchange rate is 2.5 times

per hour. In a heavily contaminated area, up to 15 air

exchanges per hour can be necessary. The factors that

determine what the rate of air exchange should be are:

• generation rates of the various pollutants;

• concentration level of the pollutants;

• desired contamination reduction level.

Airborne contaminants will always be present in the air where

contaminant generations take place. Air cleaning systems and

ventilators do not eliminate airborne contaminants, they

reduce the excessive accumulation of the contaminants. To

eliminate the contamination, the source of contamination must

be removed.

THREADED

BARREL

SPRING

LOADED

PLUNGER

WRENCH FLAT

WRENCH

FLAT

M11994

M12651A

CEILING LINE

CLEAN AIR

DISCHARGE

CEILING LINE

CLEAN AIR

DISCHARGE

PARTICLE FILTER

PREFILTER

AIR IN

AIR IN

INTAKE

BLOWER

MOTOR

AIR VENTS

CPZ™

SORBENT

FILTER

MODULE

CPZ™

SORBENT

FILTER

MODULE