11 60-2026—11

a

Currently obsolete.

Ignition Spark Response Test

Test to be sure that ignition spark is not actuating the flame

relay (usually 2K) or flame LED in the flame safeguard control.

1. Close the pilot and main burner manual fuel shutoff

valves.

2. Connect the appropriate meter to the flame safeguard

control amplifier. Start the burner and run through

the ignition period. Ignition spark should occur, but

the flame relay must not pull in or the flame LED

should not light. The flame signal should not be more

than 0.25 microamp or 1.25 Vdc with the BC7700 or

7800 SERIES.

3. If the flame relay does pull in or the flame LED lights,

reposition the flame detector to increase the distance

between the flame detector and the ignition spark. If the

flame detector is not in the line of sight of the ignition

spark but appears to respond to the spark, it may be

responding to reflected spark generated UV radiation. If

so, relocate the flame detector so it does not receive the

reflected UV radiation. It may be necessary to construct

a barrier to block the UV radiation generated by the

spark from the flame detector view.

4. Continue making the adjustments until the flame signal

due to ignition spark is less than 0.25 microamp or

1.25 Vdc.

5. The use of the Q624 or Q652 solid-state ignition

transformer may also provide a method to eliminate the

C7027A, C7035A, or C7044A flame detector response

to UV radiation generated by ignition spark. The Q624

and Q652 prevents flame detector response to ignition

spark by providing alternating periods of spark

generation and UV sensor activation. If ignition spark is

detected, try reversing the leads on the Q624 or Q652.

Response to Other Ultraviolet Sources

Some sources of artificial light produce small amounts of

ultraviolet radiation. Under certain conditions, an ultraviolet

detector will respond to them as if it is sensing a flame.

Do not use an artificial light source to check the response

of an ultraviolet detector. To check for proper flame detector

operation, test for flame failure response under all operating

conditions.

Weld The Sight Pipe (or Tighten

the C7044A Clamp Screw)

When the flame signal is acceptable after all adjustments are

made, remove the flame detector and weld the sight pipe in its

final position. If you are using a swivel mount, the pipe may

already be welded. Then reinstall the flame detector.

NOTE: If using a C7044A Detector with no sight pipe,

do not remove the detector; tighten the clamp

screw securely.

Final Checkout

Before putting the burner into service, check out the

installation using the procedures in the Checkout section of

the Instructions for the appropriate flame safeguard control.

After completing the checkout, run the burner through at least

one complete cycle to verify correct operation.

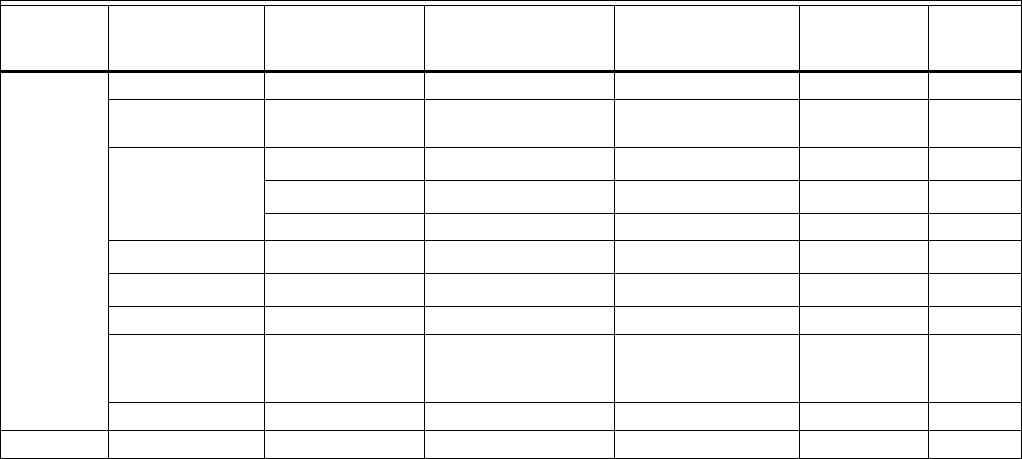

Table 1. Flame Signal.

Flame

Detector

Plug-in

Amplifier

Honeywell Flame

Safeguard

Control

Minimum Acceptable

Steady Current

(microamps)

Maximum Current

Expected

(microamps)

Minimum

Acceptable

Voltage (Vdc)

Maximum

Voltage

(Vdc)

C7027A,

C7035A,

C7044A

R7249A BC7000 + PM720 3.5 7.5 — —

R7749B

(AMPLICHECK™)

BCS7700A — — 2.2 4.98

R7249A

R4075C

a

,D

a

,E

a

3.5 7.5 — —

R4138C

a

,D

a

3.5 7.5 — —

R4140G,L,M 3.5 7.5 — —

R7290A

R4795A,D

a

1.5 2.25 — —

None

R7023C

a

1.5 2.25 — —

NONE R7795A,C,E,G 1.5 2.25 — —

R7849A or

R7849B

(AMPLICHECK™)

7800 SERIES — — 1.25 5.0

None RA890G 1.5 2.25 — —

C7927A R7851B 7800 SERIES — — 1.25 5.0