Installation

10/07 Installation and Maintenance Manual 7

3.5 Torque Recommendations

For inserting a cell in metal fittings or bushings - 40 ft-lb maximum. For inserting a cell in plastic fittings

or bushings - 10 ft-lb maximum. Always use pipe sealant (preferably Teflon tape).

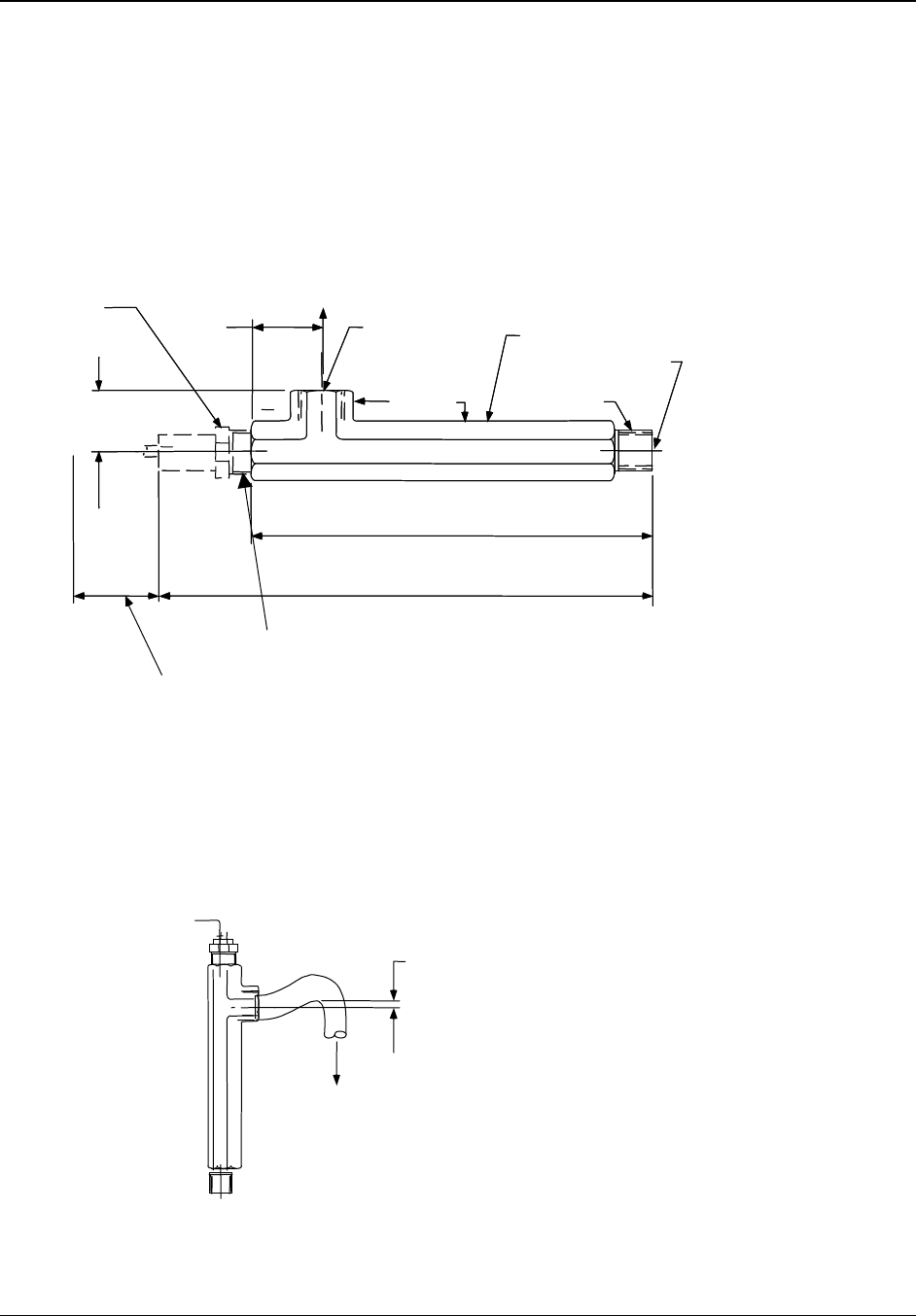

3.6 Dimension Drawings

CELL

IN

11/2"

(38mm)

83/4"

(222mm)

14 1/2" max

(368mm)

3/4" Fitting

Allow 4 1/8" (105mm) for re

CELL

IN

11/2"

(38mm)

83/4"

(222mm)

14 1/2" max

(368mm)

3/4" Fitting

Allow 4 1/8" (105mm) for re

moval of cellmoval of cell

3/4" NPT

(Male)

Flow In

Flow Chamber

11/2"

(38mm)

Octagon

3/4" NPT (Female)

Flow Out

11/2"

(38mm)

11/8"

(38mm)

Hexagon

3/4" NPT

(Male)

Flow In

Flow Chamber

11/2"

(38mm)

Octagon

3/4" NPT (Female)

Flow Out

11/2"

(38mm)

11/8"

(38mm)

Hexagon

2" min.

(51mm)

CELL I N

a/n 23342

Notes:

1. Mount cell and flow chamber horizontally as shown above with flow exit up to eliminate

possible air gap around cell body.

2. If cell and flow chamber must be mounted vertically, attach a short length of tubing to flow

exit as shown below and form a trap to ensure filling of flow chamber, especially at low flow.

Figure 3-1 Dimension Drawing for 055919 Flow Chamber