8

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

Installation (Continued)

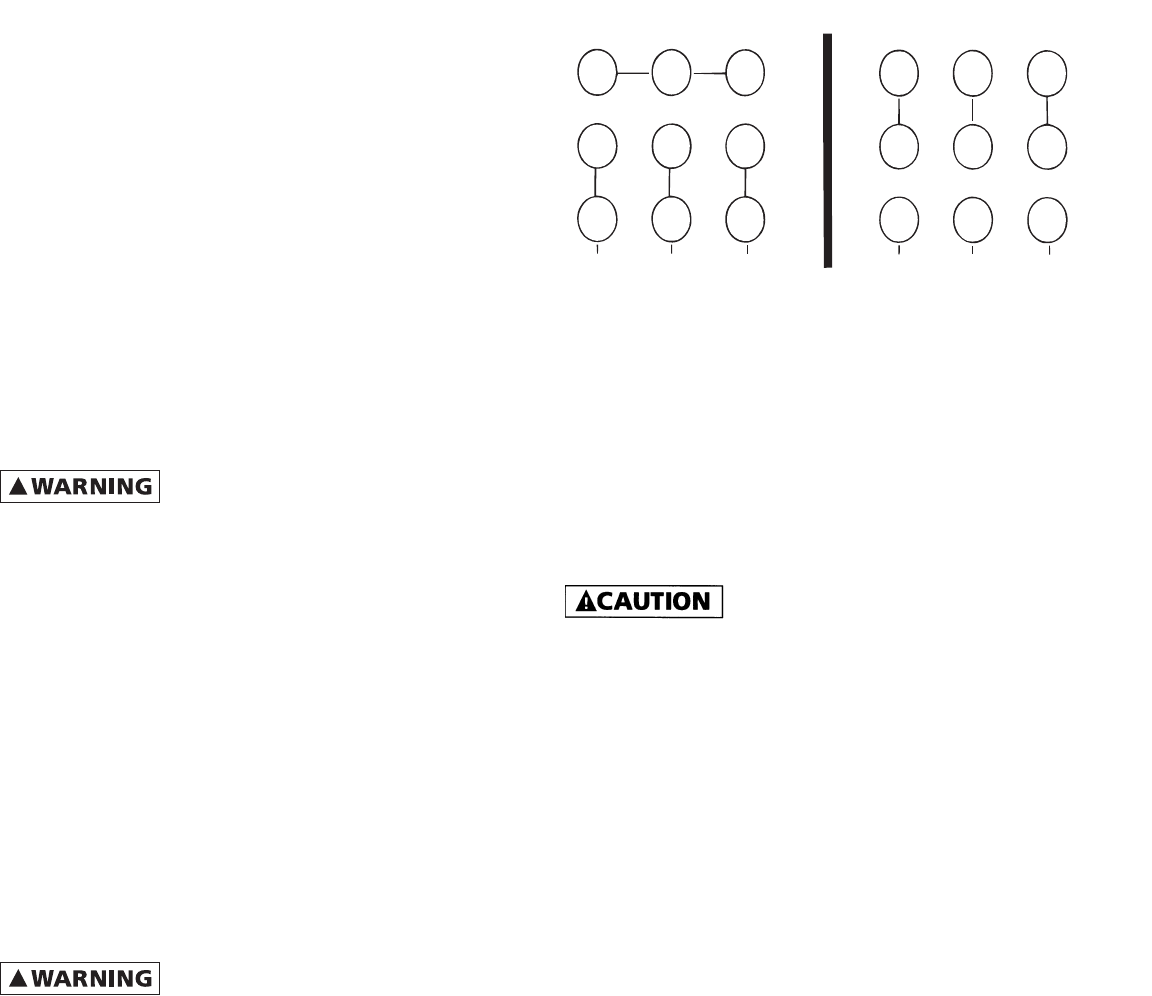

5.Specific Wiring Procedure (Refer to Figures 9, 10, & 11

and Minimum Wire Size Chart).

a. Select the voltage you are to use, either 115V or 230V

single phase, 230V or 460V three phase.

b. The 1/3, 1/2 and 3/4 HP single phase pumps are factory

connected for 115V at the motor. The 1, 1

1

/2, 2 and 3

HP pumps are factory connected for 230V at the motor.

Three phase models are factory connected for 230V at

the motor.

c. If the motor wiring must be changed to conform to your

specific voltage requirements then the motor, pressure

switch or other controls should be rewired to conform

to one of the wiring diagrams (either 115V or 230V,

single phase; 230V or 460V, three phase). Single phase 3

HP motors are 230V only and cannot be wired for 115V

service.

d. The motor wiring diagrams are Figures 9, 10, & 11 and

also are located on the motor label of the pump.

6. Remove the rear access cover of the motor.

7. Make the wiring change and replace the rear access cover.

!

Replace rear access cover before starting

or operating pump. Failure to do so can result in personal

injury.

IMPORTANT: Do not use an extension cord or splice wires.

Joints should be made in an approved junction box. If the

above information or the following wiring diagrams are con-

fusing, consult a licensed electrician.

8. All units are not supplied with pressure switches, float

devices, on/off switches, or the like (control devices).

Controls should be wired in at this time, utilizing whatever

instructions come with the controls. All units supplied

with cords, will run whenever cord is plugged into power

and will turn off whenever cord is disconnected from

power.

MOTOR PROTECTION

All single phase motors have built in thermal protection for

all voltages. The overload protects the motor against burn-

out from overload of low voltage, high voltage and other

causes. The device is automatic and resets itself once the

temperature has dropped to a safe point. Frequent tripping

of the device indicates trouble in the motor or power lines

and immediate attention is needed.

!

Never examine, make wiring changes or

touch the motor before disconnecting the main electrical

supply switch. The thermal device may have opened the

electrical circuit.

Three phase motors do not have a built in thermal protec-

tion. It is recommended that a properly sized magnetic or

manual starter (both with properly sized heaters) be used

with all three phase motors. Install starters following instruc-

tions of the starter manufacturer. See Motor Rotation under

Operation Section for changing rotation on three phase

motors.

All motors (single and three phase) should be equipped

with a correctly fused disconnect switch to provide protec-

tion. Consult local or United States National Electric Codes

for proper fuse protection based on motor data chart (See

Charts C, D and Wire chart F).

Operation

Unit must be full of fluid before operat-

ing. Do not run dry, or against a closed discharge. Do not

pump dirty water or abrasive liquids. To do so will cause

pump failure and will void the warranty.

VALVES

The inlet valve should be in the full open position and the

discharge valve should be partially open, permitting some

back pressure to be exerted against the pump when starting

up. Open valve after start up is completed.

PRIMING

NOTE: Before starting the pump it is absolutely necessary

that both the pump and the inlet pipe be completely

filled with water.

PRESSURE BOOST INSTALLATIONS

Priming is automatic when pump is connected to a pressure

source such as a hydrant or city main (See Figures 6, 7 & 8).

1. Open valves or nozzle on inlet and discharge side of pump.

2. To relieve trapped air, allow water supply to run a mini-

mum of 30 seconds before starting the pump.

IMPORTANT: An adequate flow of water going into the

pump is required so that the pumps impellers and shaft seal

do not run dry and fail.

3. If you installed a pressure gauge at the pump inlet, a read-

ing of 2 psi minimum should show whenever the pump is

in operation (See Figures 6, 7 & 8).

This reading insures that there is an ample supply of water

into the pump inlet housing.

IL0182

Low Voltage 230V High Voltage 460V

456

7

8

9

1

2

3

L

1

L

2

L

3

4

5

6

7

8

1

2

9

3

L

1

L

2

L

3

1 - Tan 4 - Yellow 7 - Purple

2 - Red 5 - Black 8 - Gray

3 - Orange 6 - Blue 9 - White

CONNECTION FOR 3 PHASE, 9 LEADS. IF YOUR 3 PHASE

LEADS ARE COLOR CODED, MATCH NUMBER ABOVE TO THE

CORRESPONDING COLOR.

NOTE: To reverse rotation, interchange any two incoming lines

(Power) leads.

Figure 11 - Wiring Diagram for Three Phase Motors