2

598-1346-00

Move ON-TIME Switch to

1, 5, or 20 minutes

Mode Switching Summary

Flip light switch

off for one second

then back on*

MANUAL MODE

AUTO

TEST

* If you get confused while switching modes, turn the

power off for one minute, then back on. After the cali-

bration time the control will be in the AUTO mode.

DualBrite

®

Timer

Light comes on half bright for selected time after dusk

(Off, 3 hr., 6 hr., until dawn). Selecting OFF disables

this feature. The motion sensing features will continue

to work as described in this manual. If motion is sensed,

the light turns on full bright for the ON-TIME (1, 5, or

20 minutes) then returns to dim mode.

Bulb Installation

NOTE: When re-lamping, turn power off and let the

fixture cool.

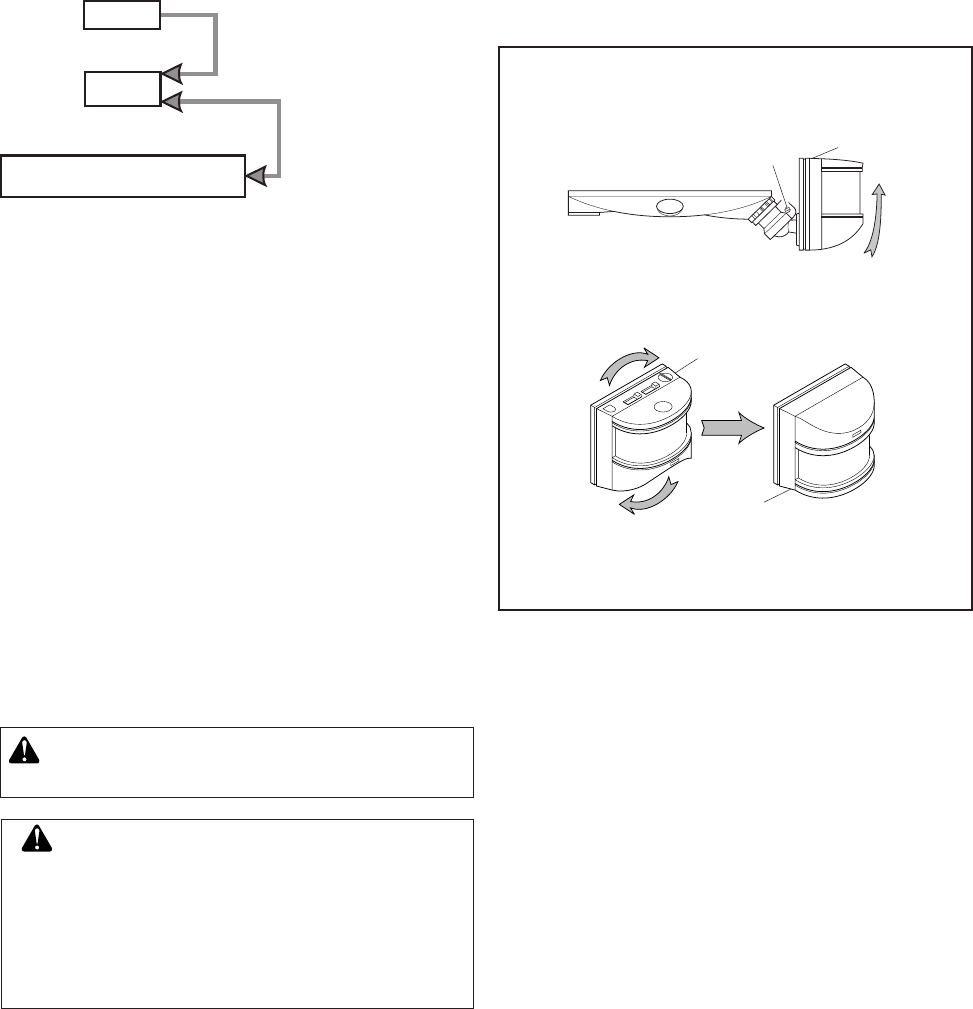

❒ To remove lamp shade, loosen set screw 2 full

turns with a small flat-head screwdriver. Turn shade

counterclockwise and remove.

❒ To remove bulb, pull straight out of fixture.

❒ To replace bulb, firmly push bulb pins into lamp

socket until completely seated.

❒ To reinstall lamp shade, place shade on fixture and

align notches on shade with tabs on fixture. Turn

clockwise. Tighten set screw firmly.

INSTALLATION

For easy installation, select an existing light with a wall

switch for replacement.

For best performance, mount the fixture about 8 ft. (2.4

m) above the ground.

NOTE:

If fixture is mounted higher

than 8 ft. (2.4 m), aiming the sensor down will reduce

coverage distance.

CAUTION: To Avoid Fire Or Burn Hazards:

• Allow fixture to cool before touching. The bulb and

the fixture operate at high temperatures.

• Keep fixture at least 2" (51 mm) from combustible

materials. Do not aim at objects closer than 3' (1 m).

• Use only T4 100W (max.), G8 tungsten halogen

bi-pin 120 VAC bulbs.

CAUTION: Keep the sensor at least 2" (51 mm)

away from the bulbs.

❒ Swing the sensor head towards the clamp

screw joint.

For eave mount only:

❒ Rotate the sensor head clockwise 180° so the

controls face down.

Controls

Controls

Clamp Screw

Controls

If the sensor pops out of the ball joint, loosen the

clamp screw and push the sensor back into the ball

joint. Tighten the clamp screw when done.

For under eave installation, the sensor head must

be rotated as shown in the next two steps for proper

operation and to avoid the risk of electrical shock.