Connect wiring to the terminal blocks

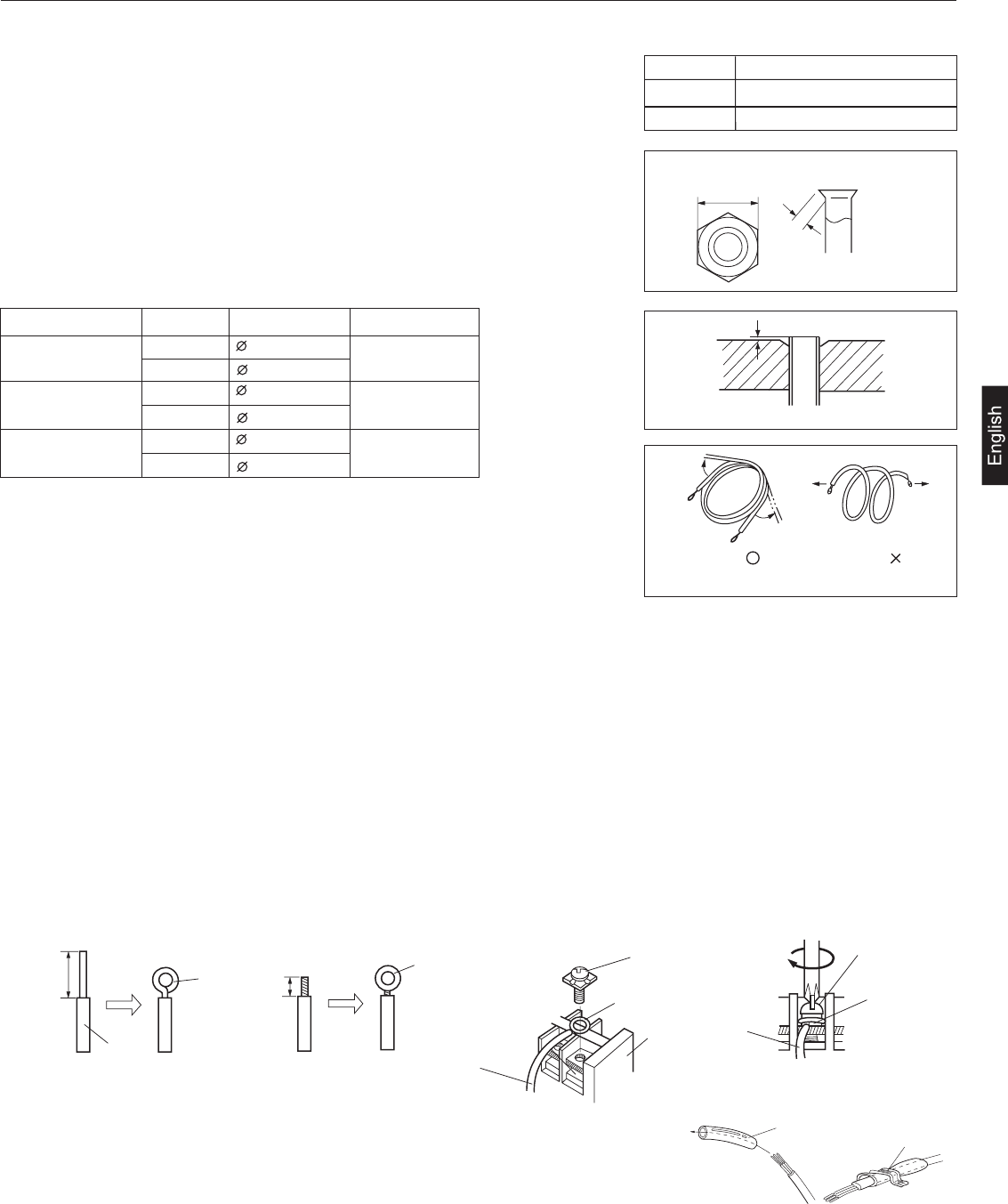

A. For solid core wiring (or F-cable) (Fig.A)

(1) Cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 25mm of the exposed solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal board.

(3) Using pliers, bend the solid wire to form a loop suitable for the terminal screw.

(4) Shape the loop wire properly, place it on the terminal board and tighten securely with the terminal screw using a screw

driver.

B. For strand wiring (Fig.B)

(1) Cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 10mm of the exposed strand wiring.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal board.

(3) Using a round terminal fastener or pliers, securely clamp a round terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten the terminal screw using a screw driver.

Insulation

Strip 25mm

Loop

A. Solid wire

Terminal

board

Screw with

special washer

Round

terminal

Wire

Screw with

special washer

Round

terminal

Wire

Strip 10mm

Round

terminal

B. Strand wire

After passing the connection cord and power cable through the insulation tube,

fasten it with the cord clamp, as shown right.

Use VW-1, 0.5 to 1.0 mm thick, PVC tube as the insulation tube.

Fix connection cord and power cable at the cord clamp

Insulation tube

Cord clamp

ELECTRICAL WIRING

CONNECTING THE PIPING

1. Flare processing

(1) Cut the connection pipe with pipe cutters so that the

pipe is not deformed.

(2) Holding the pipe downward so that cuttings cannot

enter the pipe, remove the burrs.

(3) Remove the flare nut from the indoor unit pipe and

outdoor unit and assemble as shown in Table1 and

insert the flare nut onto the pipe, and flare with a

flaring tool.

(4) Check if the flared part "L" (Fig.1) is spread uniformly

and that there are no cracks.

Table 1

Pipe Flare nut

Small pipe

Large pipe

Small (width across flats 22mm)

Large (width across flats 24mm)

2. Bending pipes

The pipes are shaped by your hands. Be careful not to

collapse them.

Liquid pipe

Diameter of pipe Dimension A (mm)

1.0~1.2

6.35mm (1/4")

Gas pipe

1.4~2.2

12.7mm (1/2")

9.52mm (3/8")

15.88mm (5/8")

Liquid pipe

Gas pipe

Installation Procedure

15

OK

NO

Extend the pipe by unwinding it

L

Width across flats

L dimension

Fig.1

Liquid pipe

1.0~1.2

6.35mm (1/4")

Gas pipe

9.52mm (3/8")

PipeModel

AC24CS1ERA

AC18CS1ERA

AC12CS1ERA

A

Pipe expander