-2-

T10667/T10668 Floating Reamer Holder

7. Turn the lathe ON and slowly apply pressure,

using the tailstock quill handwheel (after

tailstock has been locked onto the bed).

8. Feed the reamer into the barrel bore and

make cuts in short increments, stopping

frequently to remove chips from inside the

flutes.

We highly recommend that you remove the

reamer every 0.020" to 0.050" and clean off

the chips from both the reamer as well as the

bore and re-oil before continuing.

Note: Galling in the chamber from chips

packing in the flutes can tear the metal sur-

face in the bore and create grooves in the

chamber.

9. While stopping the lathe, slightly relieve the

tailstock pressure. DO NOT pull the ream-

er back before the spindle has completely

stopped, as this could scar the chamber.

10. Continue repeating Steps 3–9 until the ream-

ing process is finished. For precise results,

decrease cutting increments as you near the

end of the chamber.

3. Insert the round-nose dead center into your

tailstock.

4. Apply an ample amount of cutting oil inside

the barrel and on the cutting end of the ream-

er.

Note: You will need to continue to provide

enough cutting oil throughout the reaming

process to ensure a clean cut and tool lon-

gevity.

5. Carefully insert the reamer bushing into the

bore while supporting the reamer holder in

your hand, so the bushing does not bind.

Note: If the bushing binds, it might leave

marks inside the barrel, so it is important that

you carefully support the weight of the reamer

in your hand while inserting the length of the

bushing into the bore.

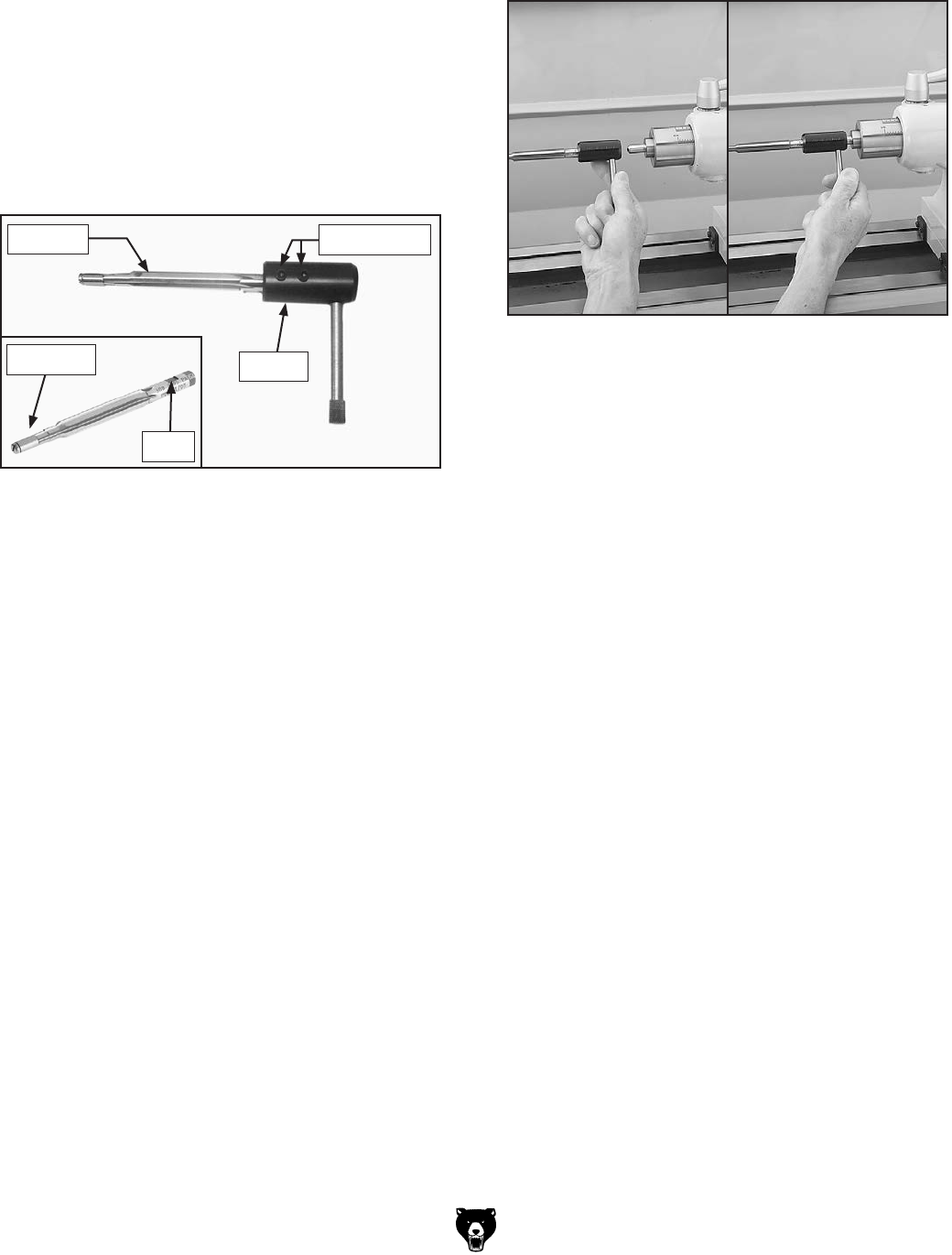

Figure 3. Inserting the dead center into the

reamer holder using the tailstock.

To use the floating reamer holder when cham-

bering a gun barrel:

1. Set up the barrel in your lathe, per your nor-

mal method, centering the bore of the barrel

as accurately as possible.

2. Assemble the reamer (not included) and

holder by inserting the reamer shank into the

holder and tightening the set screws against

the reamer flats with a 3mm hex wrench (see

Figure 2).

Holder

Figure 2. Floating reamer holder and reamer

assembled.

Flats

Bushing

Reamer

Set Screws

6. Move the tailstock forward until the rounded

end of the dead center begins to enter the

reamer holder (see Figure 3).