© May 2003 Grizzly Industrial, Inc.529003622

Putty

Glazer's

Point

Glass Pane

Gap

Step 2: Cutting Rail Ends

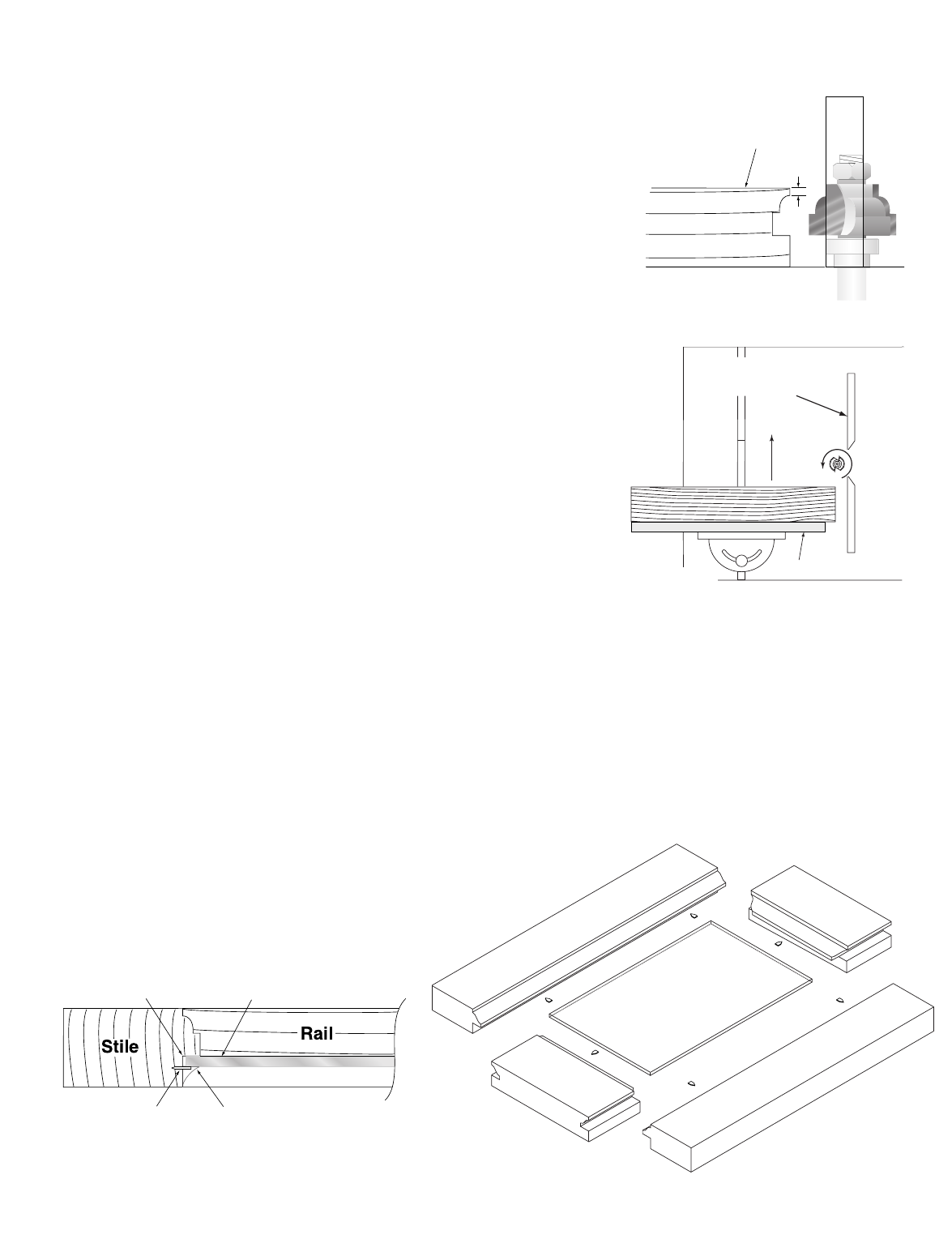

Unplug the router and change bits. Raise the router bit so the top of the bead is

1

⁄16" below the top of your stock as shown in Figure B. Make sure that the miter

gauge used passes closely enough to the router bit to give the workpiece

proper support. It is recommended an extension be applied to the miter with

screws, if the miter is more than an inch from the bit. See Figure C. Make

sure that miter and face have working clearance so they won’t come in con-

tact with bit. The miter gauge should also be checked for squareness to the

miter slot and adjusted, if necessary. The fence should be moved away so

the workpiece does not touch it during the cutting procedure. Run a test

piece which is the same thickness as your actual rail stock. Test fit the rail to

a finished stile to see how the joint looks. If the pieces do not fit together tightly,

or if the front and back surfaces do not fit flush, it may be necessary to readjust. Make very small movements in

the height of the router bit and test cut again.

When the fit is properly adjusted, make the end cuts on the rails. Double check

the fit occasionally, to insure accuracy. The workpiece must always be fed

against the cutter rotation and the full depth of profile should be made in one

pass to ensure a precise cut. Rotate the board end for end, maintaining the

face-down position and cut the other end. A clamping device may be nec-

essary to keep the workpiece secured against the miter gauge.

The position of the profile on the workpiece and variance in material thick-

ness will also affect alignment. It is therefore very important that test mate-

rial is milled to the same thickness as the finished material to ensure an

accurate setup.

Step 3: Assembly

The illustrations below show the typical style, rail and glass layout. Note the glazer’s points which secure the pane

on the back side of the frame. They can be obtained from your local hardware store along with the putty needed

to finish and seal window.

Doors having more intricate designs such as arched, tombstone or curved panels should only be done when you

are confident of your ability. If your project requires curved pieces then freehand routing using the bearing and

starter pin will be necessary.

Remember that it is important to work with good quality material and to insure that all pieces are machined the

same and that all ends and edges are cut square. Follow all recommended

safety procedures and always test the setup using sample pieces.

Router Table

Fence

1

⁄16''

Outer Side

Figure B

Miter

Extension

Fence Moved

Away from Cutter

Figure C