7

Temperature Options

Spark-Resistant Construction Options

The following AMCA Standards apply to fan

applications that may involve the handling of

potentially explosive or flammable particles,

fumes or vapors.

•AMCA Type A - All parts in contact with the

airstream are constructed of nonferrous material

(aluminum). Model SWB does not meet AMCA

Type A spark resistant construction because the

fan shaft is steel.

•AMCA Type B - The fan wheel is constructed

of nonferrous material (aluminum). A nonferrous

(aluminum) rub ring surrounds the fan shaft where

it passes through the fan housing. Available on all

SWB sizes with an aluminum wheel and rub ring.

•AMCA Type C - The inlet cone is constructed

of nonferrous material (aluminum). A nonferrous

(aluminum) rub ring surrounds the fan shaft where it

passes through the fan housing.

The constructions listed minimize the potential of

ferrous components making contact with each other

that may produce sparks. However, they do not

guarantee against the potential of producing sparks.

The installer must electrically ground all fan and

system components.

Testing

High temperature testing was conducted at

Greenheck’s Research and Development facility

with airstream temperatures in excess of 1000°F

(538°C). Temperatures were monitored at the

following critical locations throughout the tests:

bearings, bearing compartment, motor, motor

compartment, airstream and fan housing.

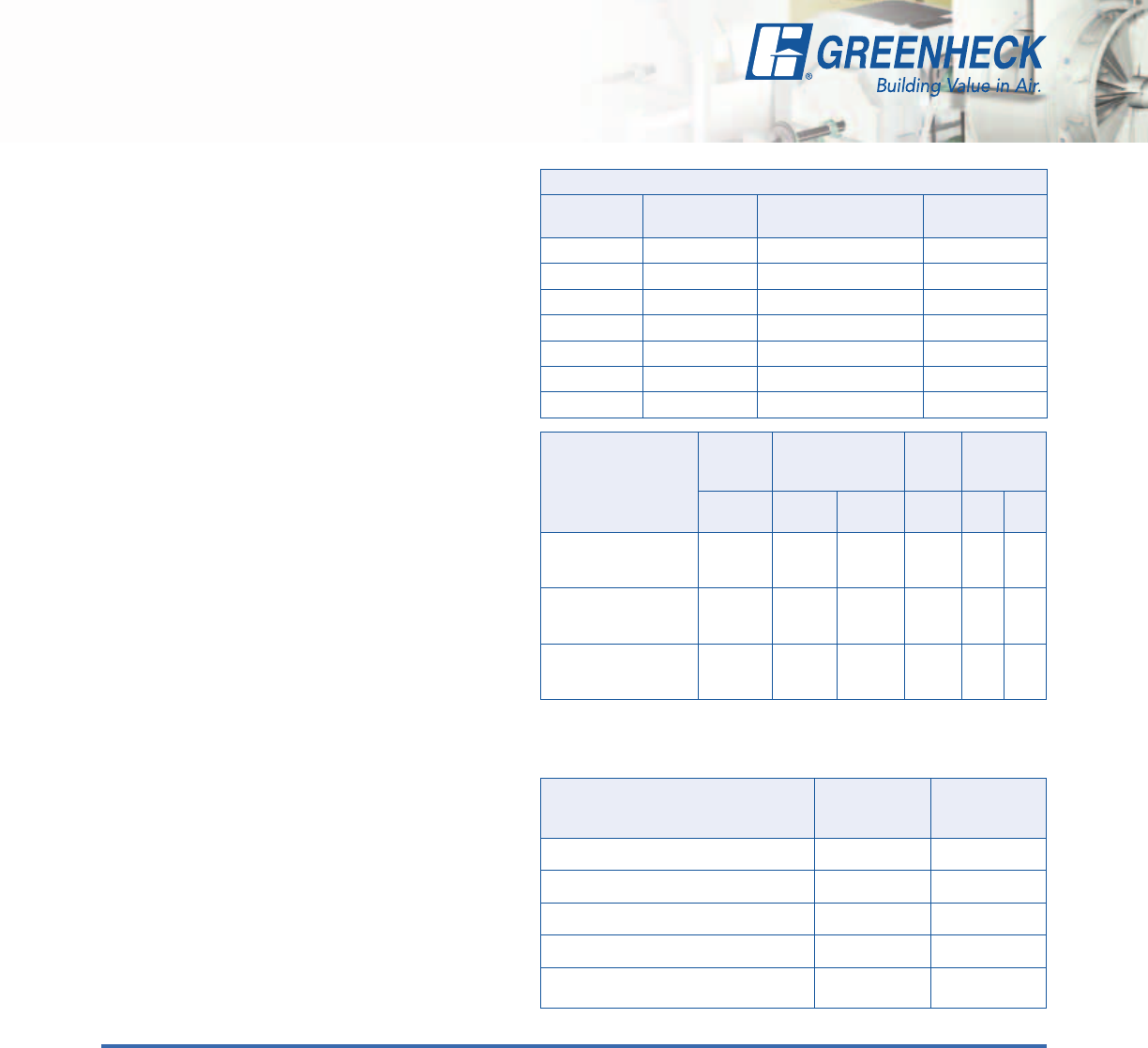

Operating Temperatures

Utility set fans are suitable for applications with

elevated temperature airstreams. Refer to the

chart at the right for operation temperature

guidelines and optional accessories.

High Temperature/Emergency Smoke Control

The SWB Series 200 sizes 212 to 224 and

Series 300 may be equipped for emergency

smoke removal applications by specifying a

high temperature option. The table below right

indicates the construction features included in

the high temperature options enabling exhaust

of heat and smoke at 500°F (260°C) for a

minimum of 4 hours or 1000°F (538°C) for a

minimum of 15 minutes.

High Temperature Option

SWB Series 200 & 300

•500°F(260°C) for a minimum of 4 hours

•1000°F(538°C) for a minimum of 15 minutes

Temperature ratings tested in accordance to UL

smoke control systems.

Emergency Smoke Control - UL Listed

SWB Series 200 & 300

•500°F(260°C) for a minimum of 4 hours

•1000°F(538°C) for a minimum of 15 minutes

High Temperature SWB Features

Series 200 & 300

High

Temperature

Option

High

Temperature

Option with UL

Steel Construction

Shaft Seal

Heat Slinger

Weatherhood

UL Label (Power ventilators for smoke

control systems)

Testing for Emergency Smoke Temperature and Time Guidelines

Code Class Tested Temperature

Time

(Hours)

IRI 500°F

(260°C) 4.00

SBCCI 1000°F (538°C) 0.25

BSI Class A 302°F

(150°C) 5.00

Class B 482°F

(250°C) 2.00

Class C 572°F

(300°C) 0.50

Class D 572°F

(300°C) 1.00

Class E 752°F

(400°C) 2.00

Operating

Temperatures

and Construction

SWB

Series

100

SWB

Series

200

SWB

Series

300

SFD, SFB

Galvanized

Painted

Steel

Aluminum

Airstream

Steel SFD SFB

-20° to 200°F

(-29° to 93°C)

Standard

201° to 300°F

(94° to 149°C)

Heat Slinger/Shaft Seal

301° to 400°F

(149° to 204°C)

Heat Slinger/Shaft Seal

The maximum continuous operating temperature on the SWB is 400°F.

For continuous operating temperatures between 401° and 1000°F use an

Arrangement 1, 9 or 10, backward-inclined centrifugal fan model BISW.