8 684025

Electrical Grounding

WARNING

4.

Spray gun or dispensing valve:

Obtain grounding

throu

g

h connection to a properly

g

rounded fluid hose

and pump.

FIRE AND EXPLOSION HAZARD

Static electricity is created by the hi

g

h velocity

flow of fluid throu

g

h the pump and hose. If your

system is not properly

g

rounded, sparkin

g

may

occur and the system may become hazardous.

To reduce the risk of static sparkin

g

which can

result in a fire or explosion and cause serious

injury, follow these recommendations for

providin

g

electrical continuity throu

g

hout your

system.

Also, read the WARNING section, FIRE AND

EXPLOSION HAZARD on page 4.

5.

Fluid supply container:

according to your local code.

6.

Object being sprayed:

according to local code.

7.

All solvent pails

used when flushing, according to local

code.

Use only metal pails

which are conductive,

placed on a positively

g

rounded surface. Do not place

the pail on a non-conductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

8.

To maintain grounding continuity when flushing or

relieving pressure,

always hold a metal part of the gun

or dispensin

g

valve firmly to the side of a

g

rounded

metal pail, then trigger the gun.

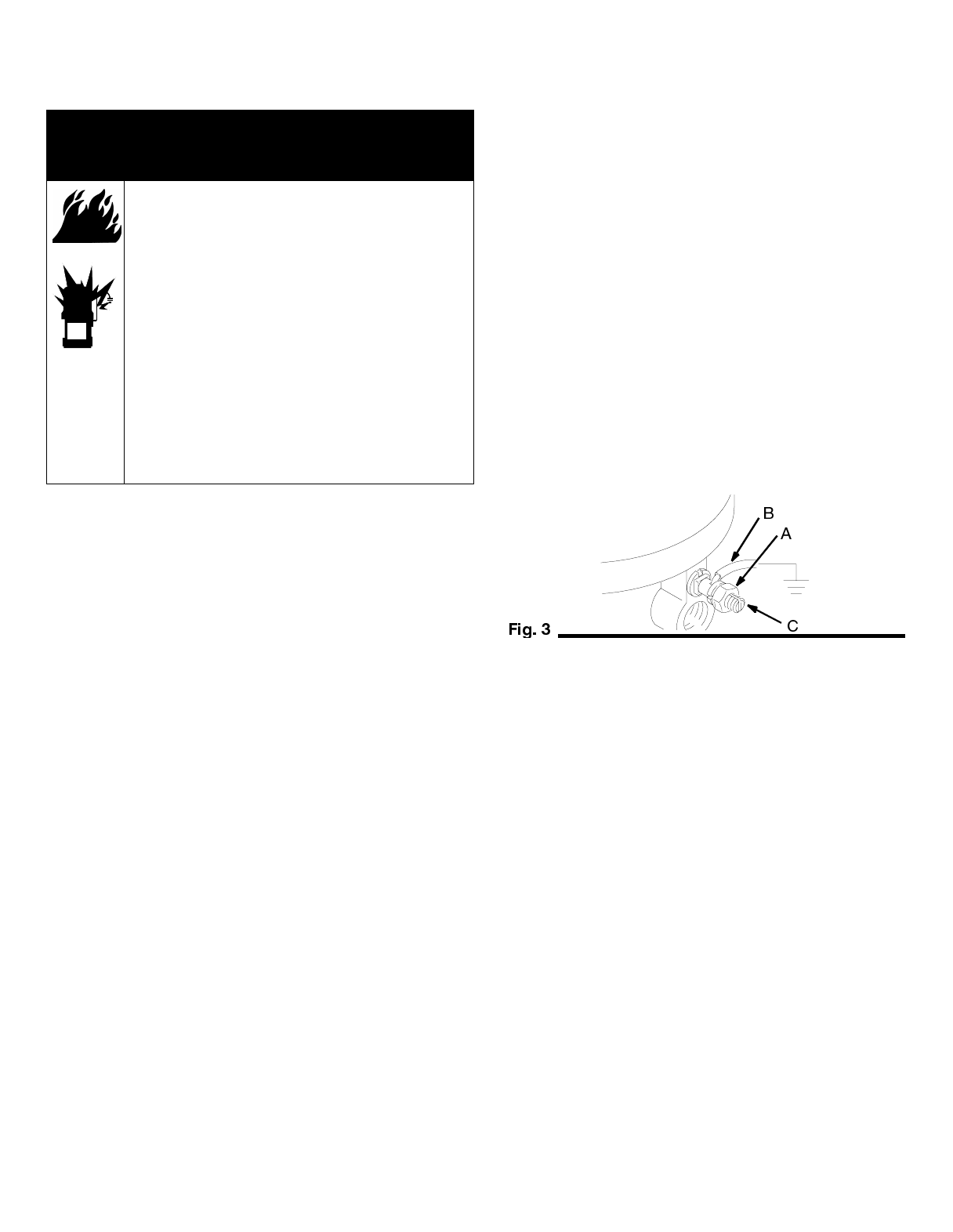

1.

Pump:

Loosen the grounding lug locknut (A) and

washer. Insert one end of a 12

g

a (1.5 m

2

) minimum

g

round wire (B) into the slot in the lu

g

(C). Ti

g

hten the

locknut securely. See Fi

g

. 3. Connect the other end of

the

g

round wire to a true earth

g

round. Order a

Groundin

g

Clamp, P/N 103538, and a Groundin

g

Wire,

P/N 208950, (25 feet (7.6 m) long, 12 ga.).

2.

Air and fluid hoses:

Use only electrically conductive

hoses with a maximum of 500 feet (150 m) combined

hose length to ensure grounding continuity.

3.

Air compressor:

follow the air compressor

manufacturer’s recommendations

0720