2 311777F

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever

you are instructed to relieve pressure, stop

spraying, check or service equipment or install or

clean spray tip.

1. Turn OFF power and turn sprayer pressure control to

lowest pressure setting.

2. Trigger gun into pail to relieve pressure.

Cleaning and Lubricating

Disassemble needle assembly and clean and grease o-rings

regularly to prolong gun life.

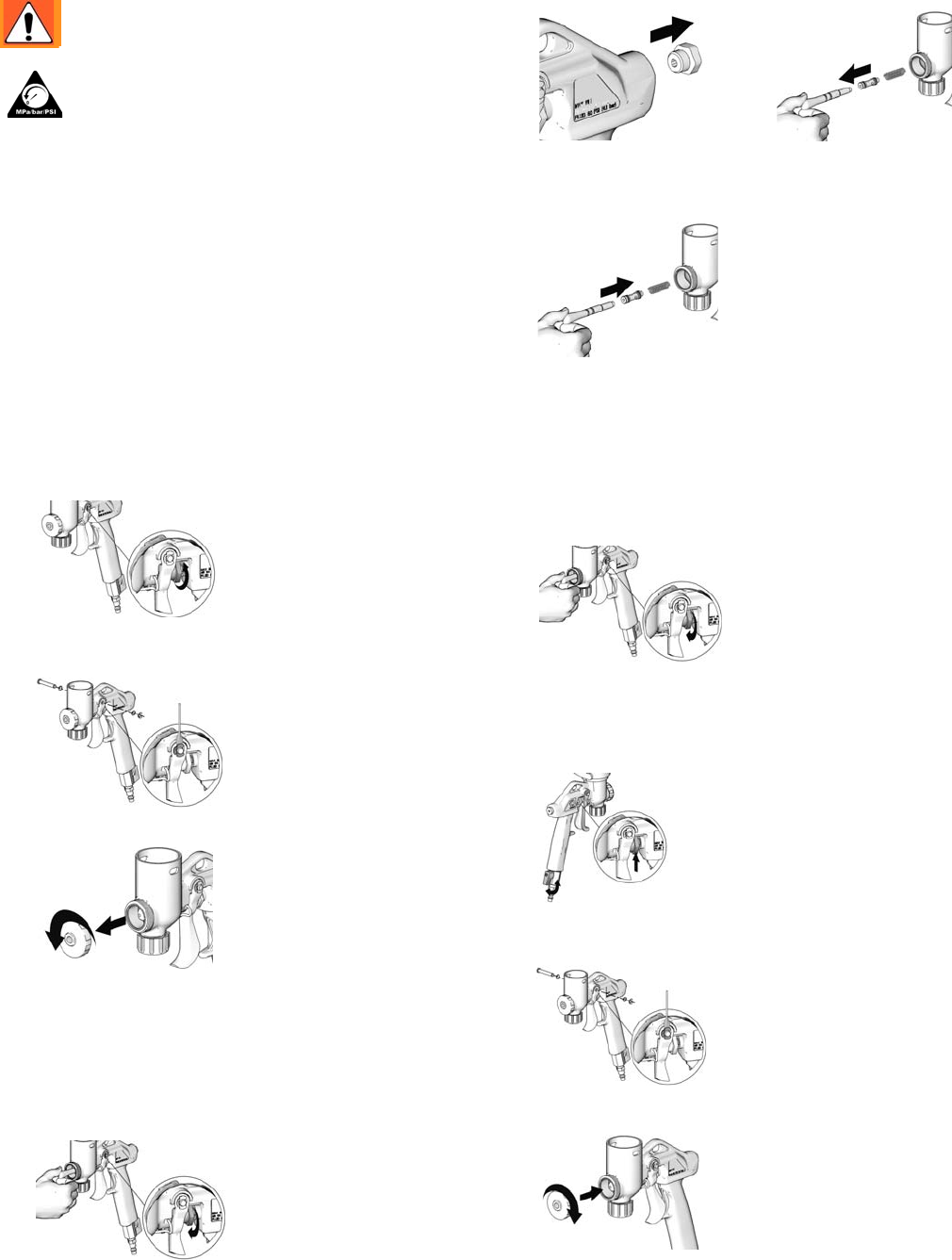

Disassembly

1. Perform Pressure Relief Procedure (see above).

2. Remove hopper or material hose from gun.

3. Clean off as much material on gun body as possible.

4. Turn flow adjustment nut counter-clockwise to enable

trigger to have full range of travel.

5. Using a small flat screwdriver, pry retaining ring off of

trigger pin. Remove pin, washer, and trigger.

6. Unscrew nozzle and remove it from gun.

7. Hold needle securely in place so it does not turn while

turning flow control clockwise until needle is disengaged

from thread and released. Pull needle and o-rings out

front of gun.

8. Hold hand under trigger area to catch adjustment nut,

spring retainer, and spring. Tap gun lightly to loosen

spring or use a small screwdriver to loosen.

9. Remove plug and use small screwdriver to remove all

components out front of gun.

Assembly

1. Hold gun as shown and insert spring in front of gun.

2. Insert spring guide with o-ring into flow adjustment nut.

Make sure the protruded end of the guide points out as

shown.

3. Position flow adjustment nut in seat on gun body.

4. Apply a generous amount of grease to o-rings.

5. Rest gun on air connection fitting. Slide needle into front

of gun.

6. While pushing needle into gun, turn flow adjustment nut

counter-clockwise to tighten needle.

7. Pull back on flow adjustment nut or continue pushing

needle in to make room for trigger.

8. Insert pin through trigger and washers. Push the retaining

clip onto the pin.

9. Pull trigger and replace nozzle.

WARNING

ti8539a

ti8530a

ti9273a

ti8538a

ti8807a

ti8806a

ti9271a

ti8538a

ti8532a

ti8530a

ti9272a