Installation

6 311304H

Installation

When unpacking pump, check for shipping damage.

Report any shipping damage to delivering carrier imme-

diately.

Mounting Pump

1. Apply PTFE thread tape (provided with the pump) to

large thread of bung adapter (9) (2 in. X 1 ½ in.

reducer fitting). Install bung adapter to fuel tank.

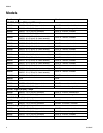

2. Assemble suction tube sections by applying ¼ in. to

½ in. wide bead of PVC cement (PN: 260086; white

tube provided with the pump) around the entire

inside diameter of the coupler (see F

IG. 1). While

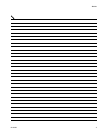

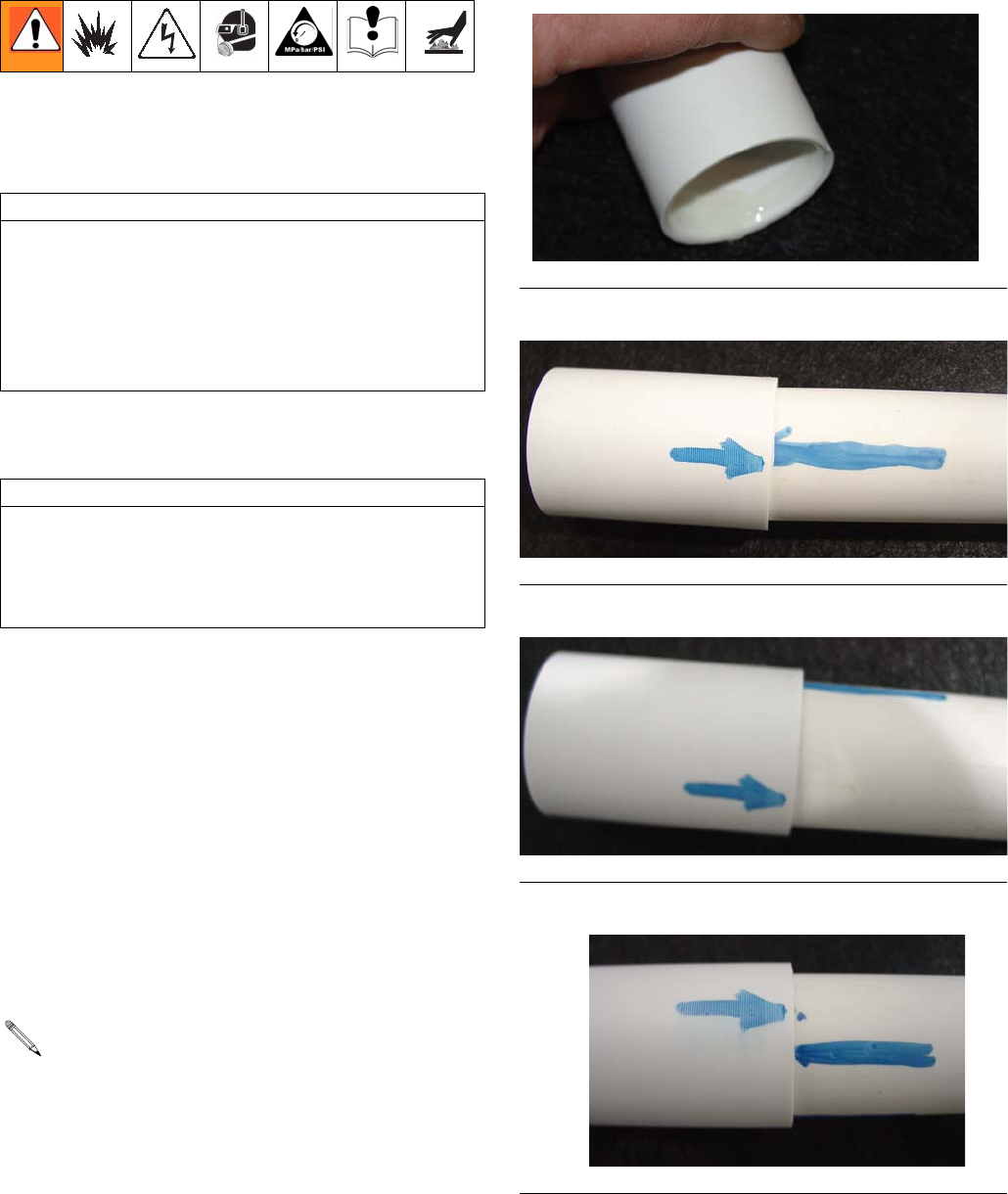

sliding the tube into the couplers turn the tube at

least one full revolution until the tube bottoms out on

the coupler (see F

IG. 2, FIG. 3, and FIG. 4). This will

allow the cement to coat the entire surface for the

best possible seal. Allow cement to set for 5 min-

utes minimum before installing pump into tank.

CAUTION

Do not use a curb pump automatic shut-off nozzle

with this pump. Use of a curb pump automatic nozzle

may cause priming problems, reduced output flow,

and motor overheating. If an automatic shut-off nozzle

is required, use Graco part number 260082 (regular)

or 260083 (unleaded) or Catlow, Inc. part number

NCLF-1 (regular) or NCNLF-1 (unleaded).

CAUTION

• Ensure tank being used is clean and free of welding

slag

• Ensure the tank is vented to allow air into the tank

as the fuel is being pumped out. Failure to provide a

vent will cause priming problems

For tanks deeper than 36 in. (914 mm) you will

need a standard 1 in. (25 mm) pipe with 1 in. npt

threads on one end. Suction tubes longer than 60

in. (1.52 m) require a foot valve (Graco Part No.

260217) at the bottom of the tube to prevent loss of

prime.

FIG. 1

F

IG. 2

F

IG. 3

F

IG. 4