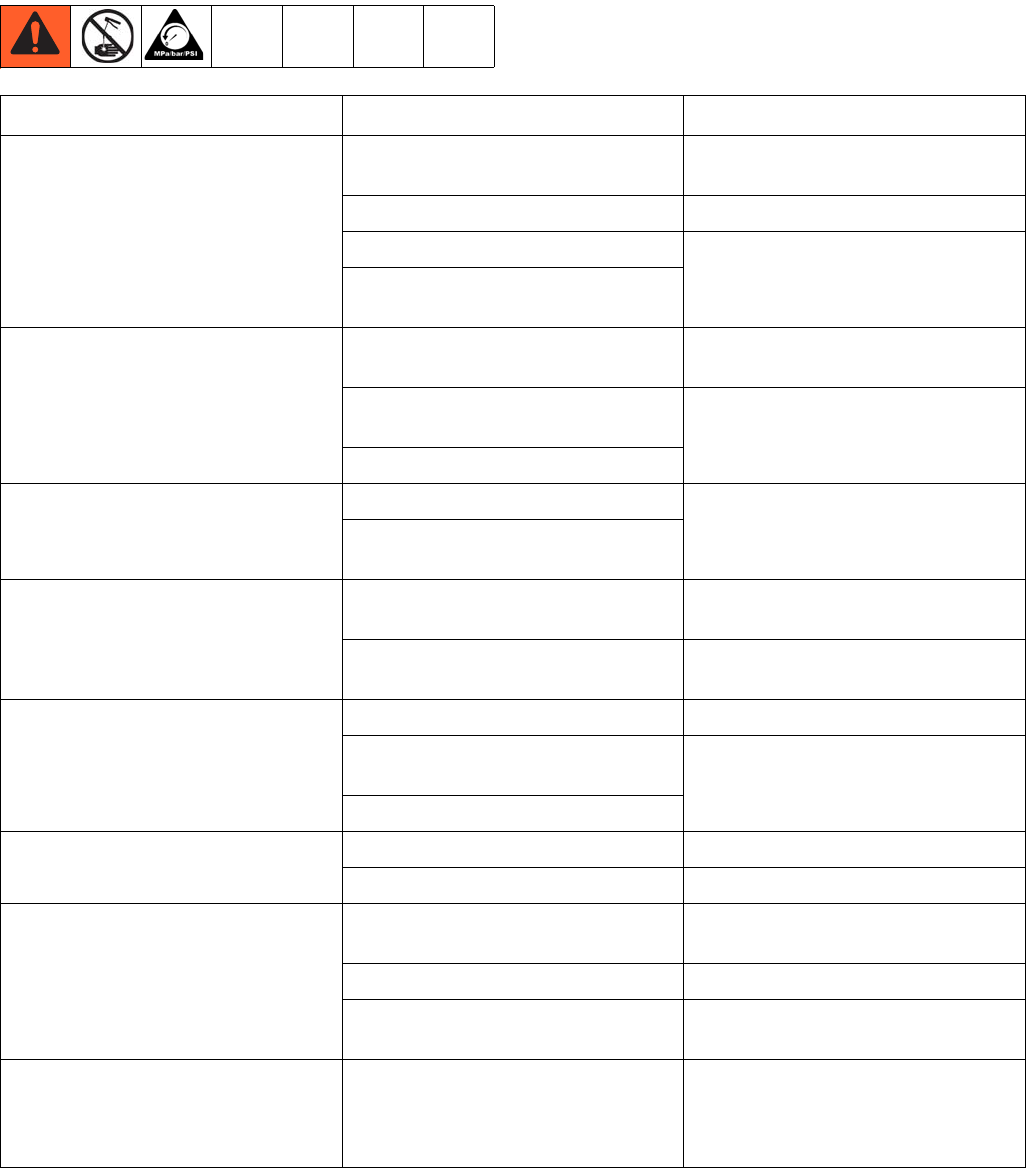

Troubleshooting

3A2257C 11

Troubleshooting

* Oil level in sight well will rise and fall during normal operation. If condition persists refer to Cause/Solution sections.

I

Problem Cause Solution

Pump does not flow

Pump stroke is adjusted to zero. Adjust pump stroke for desired out-

put. See page 8.

Pump outlet is plugged. Clean/flush pump outlet.

Outlet check valve damaged.

Replace pump.

Pump inlet check ball and/or seat is

damaged or worn.

Pump has low flow

Pump stroke is adjusted to minimal

travel.

Adjust pump stroke for desired out-

put. See page 8.

Pump inlet check ball and/or seat is

damaged or worn.

Replace pump.

Outlet check valve damaged.

Pump has low discharge pressure

Piston and bore are worn.

Replace pump.

Pump inlet check valve and/or seat

are damaged or worn.

Fluid flow from pump outlet when

pump is not running

Inlet pressure exceeds outlet check

pressure.

Reduce inlet pressure to below out-

let check pressure.

Pump outlet check ball and/or seat

is damaged or worn.

Replace pump.

Sight well fills with oil*

Possible debris in inlet check Perform Maintenance, page 12.

Pump inlet check ball and/or seat is

damaged or worn

Replace pump.

Piston and bore are worn

Sight well runs dry*

Restriction in Drip or Suction tube Perform Maintenance, page 12.

Air leak in sight well Replace pump.

Sight well remains constant and no

lubricant drips from tube

Pump air bound Follow Setup section appropriate for

your pump model, pages 5-8.

Pump regulation set too low Increase pump regulation.

Camshaft speed too slow Increase camshaft speed (see Table

1, page 10.

Cloudy or broken sight glass (Suc-

tion or Gravity Fed Pumps only)

NA Replace sight glass using GBL7500

Sight Glass Replacement Kit

24T306. See Maintenance, page

12.