Setup

8 3A2257C

Connecting Lube Lines to Pump: Suction,

Gravity and Pressure Fed Pump Models

Only

NOTE: The lube line refers to the outlet line supplying

lubricant to the lubrication points.

1. Apply thread sealant (user supplied) to lube line fit-

ting.

2. Connect lube line to pump outlet (6), (F

IG. 8)(also

see pages 15 and 16).

3. Torque lube line fitting to 50 +

5 in. lbs (5.65 + 0.6

N.m).

If inst

4. If installed, close the drain valve, located down-

stream from the pump.

5. Hand prime the pump until clean, air-free oil is flow-

ing through the lube line.

6. Connect the lube line to the lube point.

7. After startup, adjust individual pumps to meet

required flow rates. See Adjusting the Pump, page

8.

Alarm Models Only: Installing Pressure

Sensor (see Alarm Pump, page 17)

1. Apply thread sealant (user supplied) to pressure

sensor.

2. Install pressure sensor into sensor output (3) (F

IG.

7).

NOTE: Sensor output will open at 100 - 200 psi

(6.89 bar, 0.68 MPa).

3. After startup, ensure sensor is activating correctly.

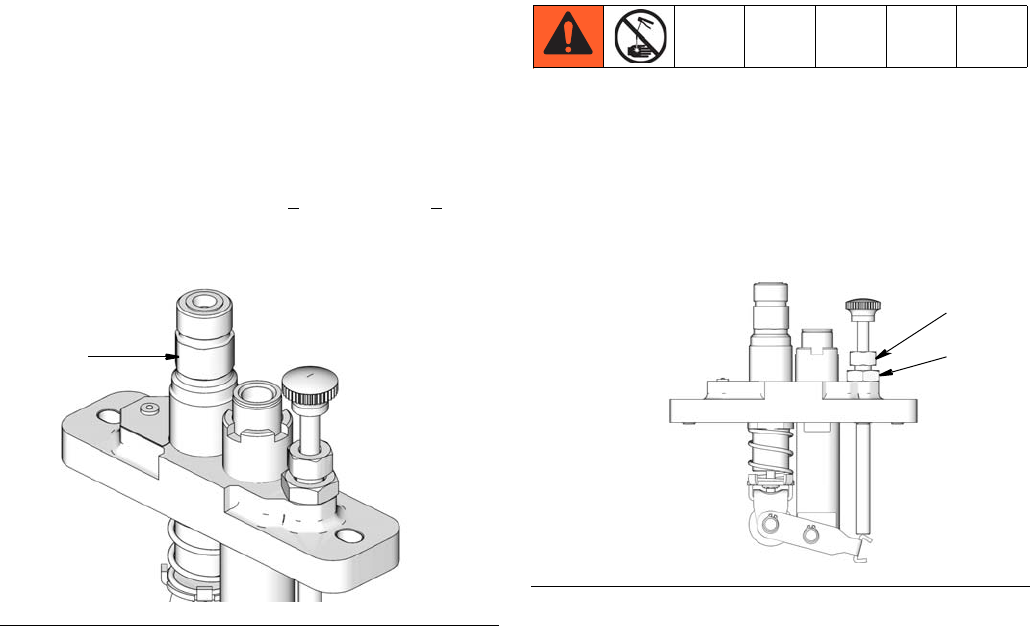

Adjusting the Pump

Pump volume is controlled by an external adjusting

screw (8) (F

IG. 9). Turning the adjusting screw changes

the length of the piston stroke which changes the pump

discharge volume.

1. Loosen the adjusting screw locknut (9) (F

IG. 9).

2. Turn the adjusting screw (8) (F

IG. 9):

• Counterclockwise - increases discharge volume

(drops per stroke)

• Clockwise - decreases discharge volume (drops

per stroke)

FIG. 8

6

I

FIG. 9

9

8