Repair

12 308777L

7. Before installing the lock wires (28) in the adjusting

nuts (27), use the special gauge, 171818, to adjust

the transfer valve (M) so there is 0.125 inches (3.68

mm) clearance between the poppets (37) and the

piston (5) when the toggle assemblies are in the

down position.

8. Snap the toggle assemblies (K) to the up position.

Reinstall the cylinder (32) and cap nut (31). Reas-

semble the air motor to the displacement pump.

9. Before remounting the pump, connect an air hose

and run the pump slowly, at about 40 psi (0.28 MPa,

2.8 bar) to ensure that it operates smoothly.

10. Reconnect the ground wire before regular operation

of the pump.

Throat Packing Service

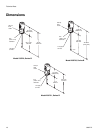

See FIG. 6 on page 12 and the Parts drawing and list

(page 13 and 14) for further information.

1. Clamp the pump in a vise and unscrew the riser

tube (80) from the air motor base (56). Pull the riser

tube away from the air motor until the cotter pin (60)

which secures the displacement pump connecting

rod to the air motor piston rod (52) is visible. (F

IG. 6)

2. Remove the cotter pin (60) and unscrew the pump

connecting rod (79) fro the air motor piston rod (52).

Remove the cylinder (32) from the air motor base

(56) as described in the Disassembly section on

page 10).

3. Remove the louvered air exhaust plate (36) and

unscrew the throat packing nut (45), using a span-

ner wrench or a 0.22 inch (5.6 mm) diameter rod.

(F

IG. 6)

4. Remove the packing nut (45), male and female

glands (47 and 48), v-packings (49), washer (44),

bearing (46), retainer (24), wiper (22), o-ring (23),

u-cup (25), and washer (26) from the base.

5. Clean the throat packing area in the base and the

packing nut. Clean and inspect all parts, and

replace as necessary.

6. Lubricate the packings, piston rod, and piston flange

with a light, water-resistant grease.

7. Install the washer (26) into the base. Assemble the

packing (25) and the wiper (22) into the retainer

(24). Install the o-ring (23) onto the retainer, and

insert the retainer assembly into the base.

NOTE: Make sure the packing (25) lips face down, and

make sure the wiper (22) lips face up.

8. Insert the bearing (46) and the washer (44) into the

base. Assemble the female gland (48), v-packings

(49), and the male gland (47) into the packing nut

(45).

9. Reinstall the spacer and packing in the base and

packing nut (45). Screw the packing nut into the

base, and tighten it securely. Carefully slide the pis-

ton rod (52) down through the throat packing, and

lower the piston into the base. Reinstall the plate

(36) and cylinder (32). Reassemble the air motor to

the displacement pump.

10. Torque the outlet adapter (42) to 45 to 55 ft-lbs (61

to 75 N.m).

The piston in the air motor, located behind the air motor

plates, moved when air is supplied to the motor. Moving

parts can pinch or amputate your fingers or other body

parts. Therefore, never operate the pump with the air

motor plates removed.

NOTICE

When reinstalling cotter pin (60), always spread and

flatten the pin (both the head and prongs) around the

rod to within 1 inch (25 mm) total diameter. See Detail

A of F

IG. 6.

FIG. 6

45

36

80

56

32

SEE DETAIL A

52

60

79

1 in.

(25 mm)

DETAIL A