307843 7

Installation

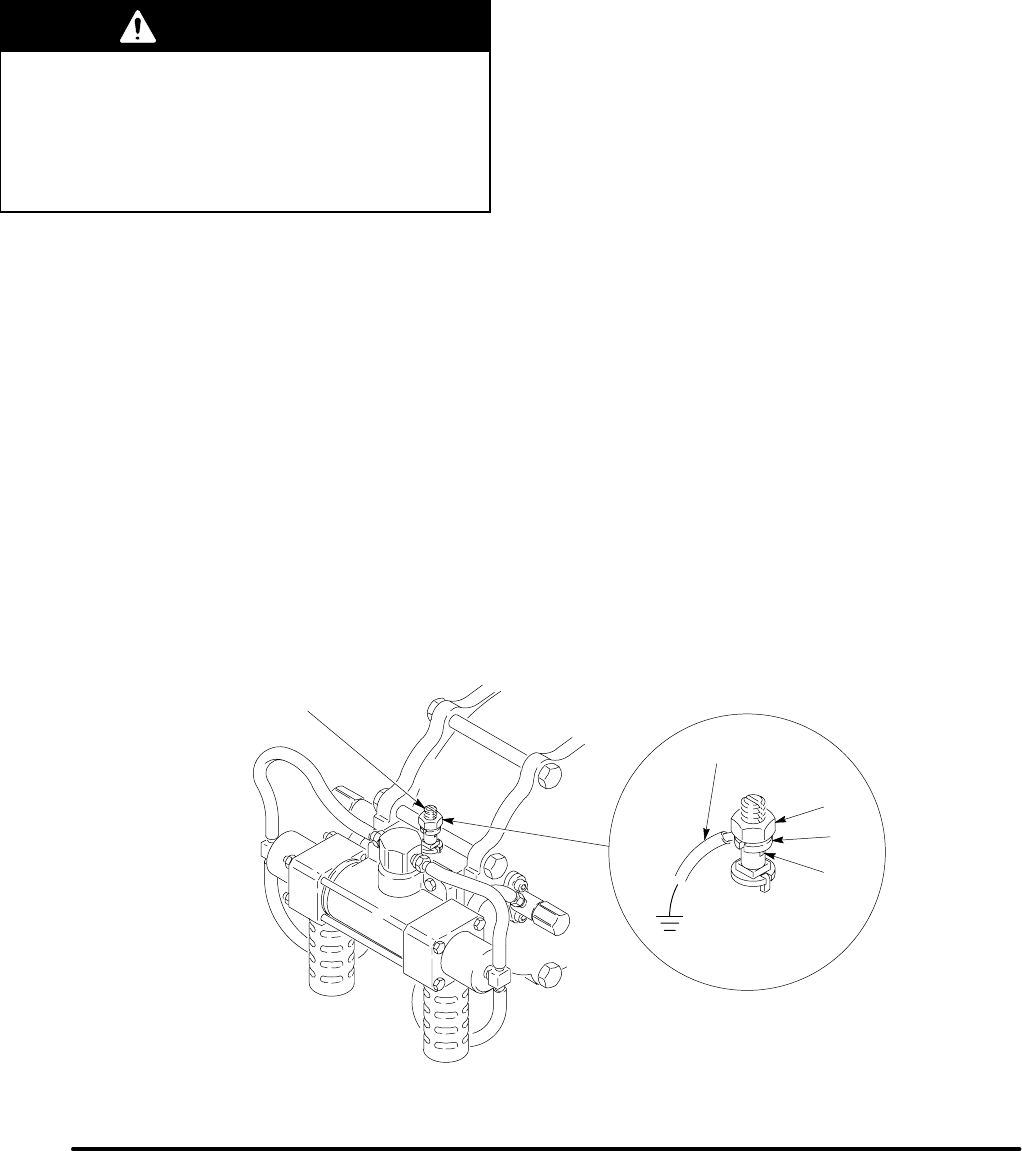

Grounding

WARNING

This pump must be grounded. The steps for

grounding may differ from the way you ground

other pumps. Carefully read and follow these

grounding instructions. See FIRE AND EXPLO-

SION HAZARD on page 5 before you operate the

pump.

Static electricity is created by the high-velocity flow of

fluid through the pump and hose. If every part of the

equipment is not properly grounded, sparking may oc-

cur. To reduce the risk of static sparking, ground the

pump and all other equipment used or located in the

pumping area. Check your local electrical code for de-

tailed grounding instructions for your area and type of

equipment. Ground all of the following equipment:

D Pump: use a ground wire and clamp as shown in

Fig. 2.

D Fluid and air hoses: use only grounded hoses with

a maximum of 500 feet (150 m) combined hose

length to ensure grounding continuity.

D Air Compressor: Follow the manufacturer’s recom-

mendations.

D Spray gun or dispensing valve: Obtain grounding

through connection to a properly grounded fluid

hose and pump.

D Fluid supply container: Follow the local code.

D Object being sprayed: Follow the local code.

D All solvent pails used when flushing: Follow the

local code. Use only metal pails, which are conduc-

tive. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which inter-

rupts the grounding continuity.

To ground the pump: Loosen the grounding lug lock-

nut (W) and washer (X). Insert one end of a 12 ga (1.5

mm@) minimum ground wire (Y) into the slot (Z) of the

grounding lug, and tighten the locknut securely. Con-

nect the clamp end of the ground wire to a true earth

ground. To order a ground wire and clamp, order Part

No. 222011.

Fig. 2

02322

Z

W

X

Y

grounding lug