12 309303

Maintenance

Tightening Threaded Connections

Before each use, check all hoses for wear or damage.

Replace as necessary. Check that all threaded con-

nections are tight and leak-free.

NOTE: Periodically, re–torque fluid cover screws (38)

to 10 ft–lb (13.6 NSm).

Cleaning

Clean the outside of the equipment daily, using a soft

cloth and compatible solvent.

Clean the suction tube (L) and inlet strainer daily, using

a compatible solvent.

Clean the air filter (D) in your main air line at least

once a week.

Storage

Before storing the pump, always flush it and relieve

pressure.

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based

on the pump’s service history. This is especially impor-

tant for prevention of spills or leakage due to dia-

phragm failure.

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 11.

1. Relieve the pressure before checking or servicing

the equipment.

2. Check all possible problems and causes before

disassembling the pump.

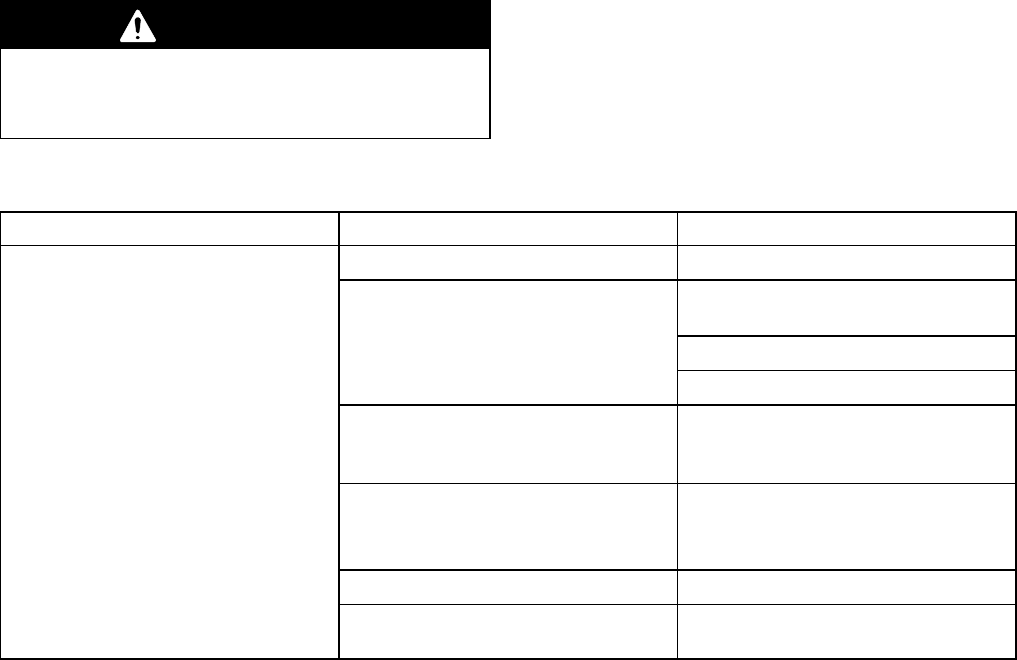

PROBLEM CAUSE SOLUTION

Pump will not run.

Closed air line valve. Open valve.

Inadequate air supply, or clogged/

restricted air line.

Increase air supply. Do not exceed

maximum air inlet pressure.

Open or clear air line.

Clean air filter.

Clogged pump, fluid line, or spray

gun.

Clear, service. Flush regularly. Do

not allow fluid to set up in the pump

and lines.

Stuck or damaged pump air valve. Disassemble and clean air valve.

Replace worn parts. See page 18.

Use filtered air.

Ruptured diaphragm. Replace diaphragms. See page 17.

Air valve plate installed incorrectly. Align plate with center housing. See

page 19.