307843 13

Troubleshooting

SYMPTOM PROBABLE CAUSE TEST PROCEDURE REMEDY

3. Pump runs but

does not main-

tain constant

pressure

a. Air in fluid line

b. Air line too small

c. Obstructed or worn ball

(57) and seat (49)

d. Worn fluid piston (17)

and/or piston seal (13)

e. Air control valve

mufflers (38) plugged

f. Air control valve dirty or

worn

g. Lack of lubrication

h. Dirty air passages

a. Check for spitting at

fluid line outlet

c. Pump fast cycles on

one end of stroke

indicates that side is by-

passing

d. Pump fast cycles on

one end of stroke

indicates that side is by-

passing

e. Check for slow air flow

at muffler

g. Pump reacts slowly

h. Check for sluggish air

control valve operation

a. Bleed fluid line until con-

stant flow is

obtained

b. Install larger air line,

minimum size 1/2 in.

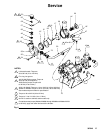

c. Remove, clean, and in-

spect seat, ball, and ball

guide (56). Replace if

worn. See page 15.

d. Replace piston and/or

seal. See page 16.

e. Remove and clean muf-

flers

f. Repair or replace air

control valve. See page

20.

g. Adjust lubricator

h. Clean air passages; do

not enlarge orifices.

Empty air line filter and/

or control valve filter

(40q). See step 5 in Dis-

assembly on page 20.

4. Paint dripping

externally

around piston

rod

a. Ruptured bellows seal

(14)

a. Check for presence of

paint around piston

shaft (15)

a. Replace bellows seal.

See page 16. Be sure

to suction feed, not

pressure feed, pump.

Maximum fluid inlet

pressure is 15 psi (104

kPa, 1.04 bar)