9

IO-230F 08/04

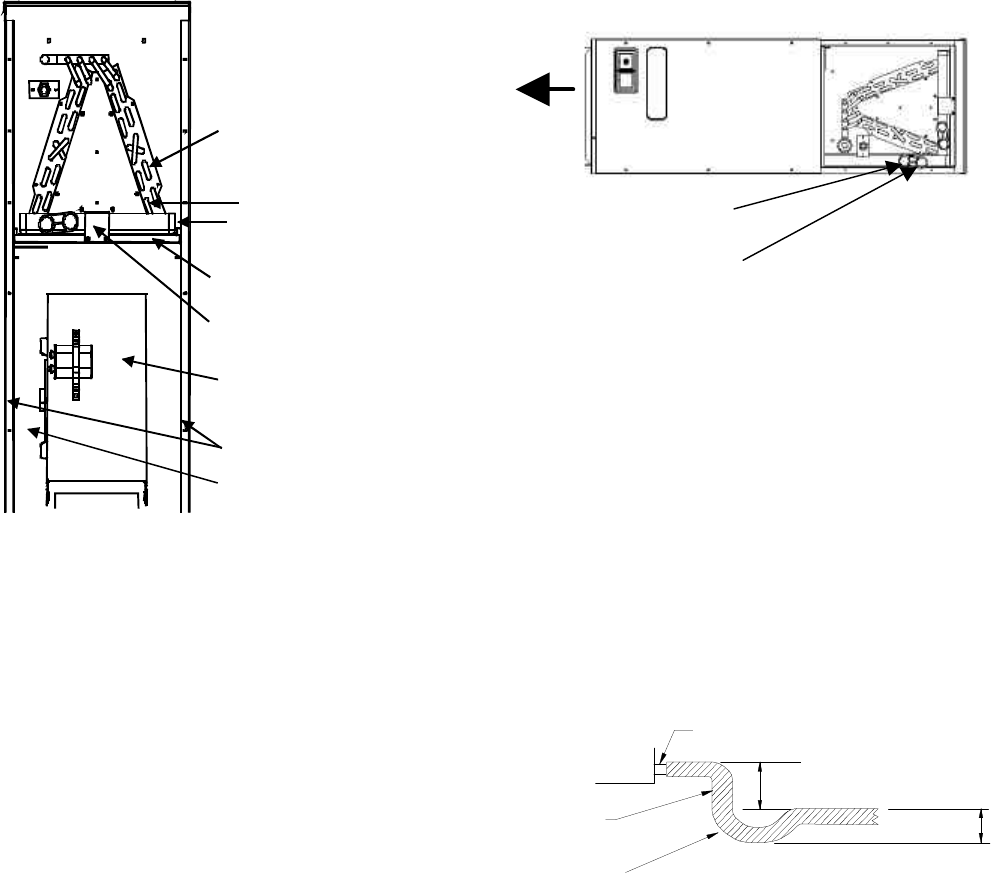

To complete the conversion, slide the evaporator coil into

the chassis and attach the three (3) access panels.

(Figure

7).

CONVERSION TO HORIZONTAL

The “B” series product is not suitable for horizontal

application and must not be used for this type of installation.

The following describes converting to “Horizontal Left-

Hand”. The only field modification required for conversion

to “Horizontal Right-Hand” is the removal of the plastic

knockouts in the horizontal panel drain connections.

TOP OF WRAPPER

INSULATION JACKET

ZEE COIL SUPPORT

WRAPPER STIFFENER

DRAIN PAN INSULATION

DPI KIT (HATCHED AREA)

NEOPRENE GASKET

MOTOR

BLOWER

Figure 7

As shown in Figure 8, it is recommended that the

conversion to horizontal be performed before placing the

air handler in its final location and in an area that allows for

access to all sides.

1. Remove the (3) air handler access panels.

2. Remove the “J” shaped bracket that retains the

evaporator coil.

3. Remove the flowrater (or TXV) from the lower left side

access panel and slide out the evaporator coil and

horizontal drain pan.

4. Remove the gasket from the horizontal pan drain

connections.

5. Remove the oval shaped plastic plug from the left side

access panel. Remove the oval shaped rubber gasket

seal from the lower right side access panel.

6. The drain connections for the horizontal pan are sealed

with a thin coating of plastic. Carefully knock out this

plastic seal with a screwdriver and hammer. Note:

The upper drain will become the secondary drain

which is mandatory in many municipalities .

7. Install the plastic plug removed in step 5 to the right

side lower access panel and the oval shaped rubber

gasket to the lower left access panel.

8. Reinstall the evaporator coil with the horizontal panel

on the left side. Note: Push the assembly completely

to the rear to ensure the engagement of the upflow

pan with the rear channel bracket.

9. Install the “J” bracket (removed in step 2) to support

the upflow pan to the tie channel.

10. Attach all panels and the refrigerant management

device.

Secondary Drain

Primary Drain

Figure 8

CONDENSATE REMOVAL

The drain pan has a primary and secondary drain

connection (Figure 8). Condensate removal is performed

by attaching a ¾” PVC pipe to the evaporator coil pan and

terminated in accordance with local or state Plumbing/

HVAC codes. The installation must include a “P” style trap

that is located as close as is practical to the evaporator

coil. Exercise caution not to over-tighten the drain

connection(s) in order to prevent possible damage to the

evaporator drain pan. See Figure 9 for details of a typical

condensate line “P” trap.

Installations that are above a finished ceiling may require

a field supplied auxiliary drain pan. Consult local codes on

this requirement.

DRAIN

CONNECTION

2" MINIMUM

3" MINIMUM

POSITIVE LIQUID

SEAL (REQ'D)

UNIT

FLEXIBLE

TUBING (HOSE

OR PIPE)

Figure 9

Use of a condensate removal pump is permitted when

necessary. This condensate pump should have provisions

for shutting off the control voltage should a blocked drain

occur. A trap must be installed between the unit and the

condensate pump.