8

LP122A Series/LP123 - Repair Instructions

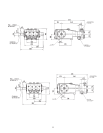

1. With a 30mm wrench, re-

move the six (6) plugs (48)

from the valve casing (43).

Inspect the o-rings (48A)

and replace if necessary.

Remove the complete valve

assembly (46A) by thread-

ing a 12mm bolt into the

spring retainer and pulling

straight out.

2. To disassemble the valve, screw the bolt into the retainer until

the valve plate (45) presses the valve seat (44) out of the spring

retainer. Examine all parts and replace if necessary. If the seat

doesn’t come out, use a valve puller to remove.

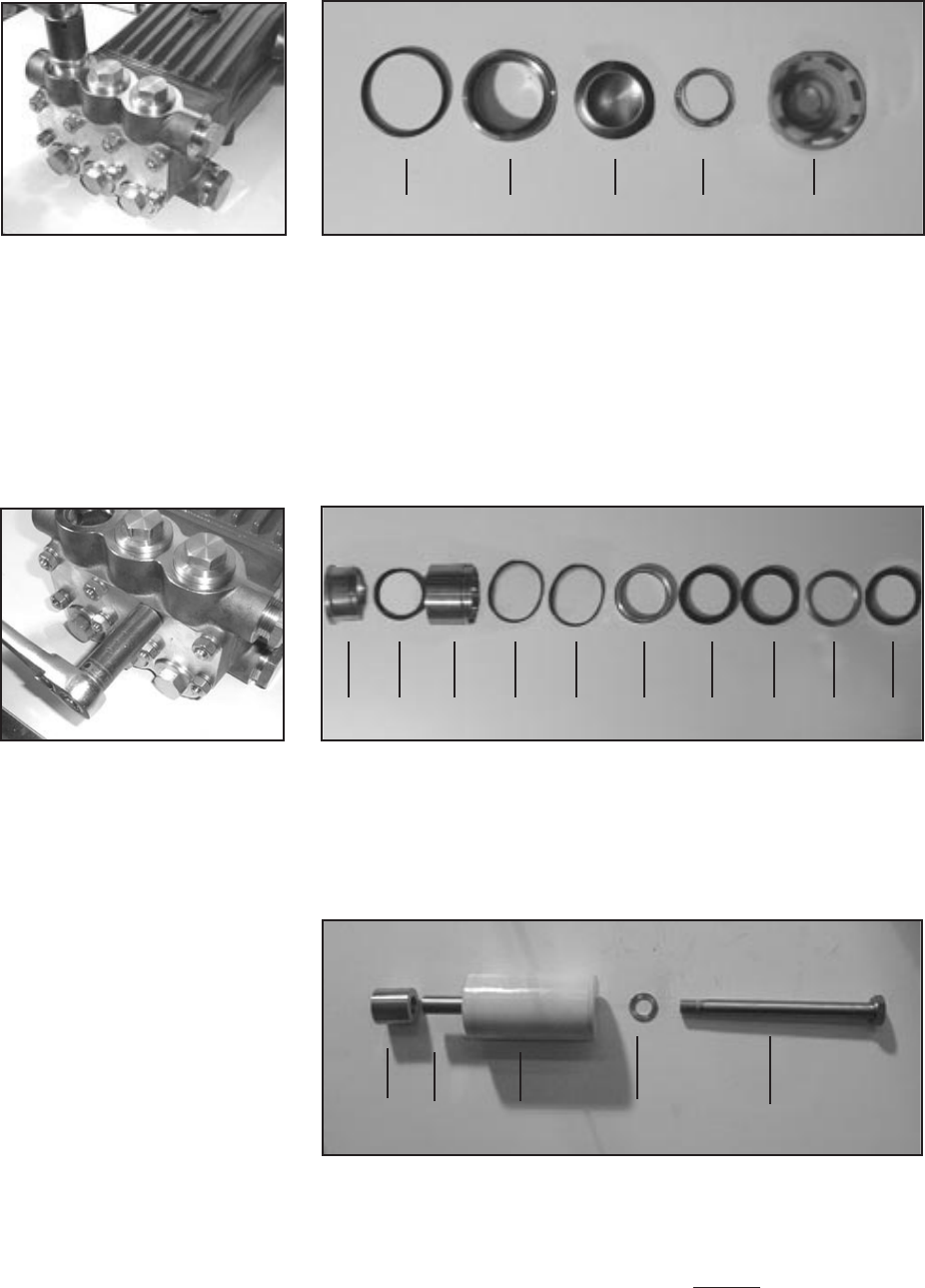

3. Remove the eight (8) hex

nuts (49A) with a 19mm

wrench. Tap the back of

the manifold (43) with a

rubber mallet to dislodge

and slide off the studs.

4. Remove the seal sleeve (35) from the manifold and/or crank-

case. Remove the pressure rings (39&36A), v-sleeves (40&36),

support ring (41) and o-rings (35A and 35B in Lp255A only)

from the manifold and seal sleeve, respectively. For LP255

only, remove support ring (37). Examine seals carefully and

replace if worn. Clean all parts.

6. Inspect surface of plunger pipe (29B) carefully. Remove any

chemical or mineral deposits taking care not to damage the

surface of the plunger. If plunger pipe is worn, remove the

plunger bolt (29C) , plunger pipe (29B) and spacer (29E).

Replace worn parts necessary. Note:

Always use a new copper

gasket (29) when repairing the plunger assembly.

5. If there are signs of oil

leaking through the

plunger oil seals, then

replacment is

neccessary.For

LP122A &

LP122A-4000, remove

the plunger pipe (29B)

before inspecting oil

seals (31A & 33).

For the LP123 &

LP122A-3100

dissassemble the gear

end and push out the

seals from the back of

the pump.

29E 29A 29B 29D 29C

36A 36 35 35A 35B 39 40 40 41 37

(LP255 only) (LP255 only)

44A 44 45 48 47