Supplementary Plant Lay-Out Instructions - LP121HT PUMP

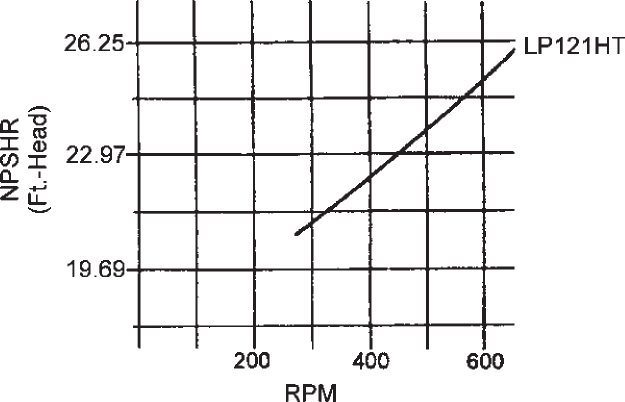

Pressure in Inlet Side

The stipulated NPSHR is the minimum required pressure above the vapor pressure of the

medium and is never to fall short of this figure. Temperature and vapor pressure of the

medium, the geodetical height of the location, the flow rate and the loss of friction in the

suction line, must all be taken into consideration. It may be necessary to install a booster

pump (centrifugal) in the suction line.

Pulsation

Due to its construction, the plunger pump creates pulsation in the inlet and discharge lines.

In particular, inlet pulsation must be dampened in order to prevent resonance in the suction

line which in turn causes cavitation. Therefore, the pump is never to be connected by a

rigid pipe. Rather, use a flexible hose, which is not reinforced by steel, that is 1.5 to 2

times wider than the inlet port. If a booster pump is used, the hose is to be attached

between the booster pump and the high pressure pump.

If several pumps are used, each pump must have its own inlet line. If this cannot be done,

an inlet air chamber or inlet flow stabilizer must be installed in front of each pump. The

bladder in the stabilizer is to be pre-tensioned on location.

Depending on the layout of the plant, a pressure accumulator may be necessary on the

discharge side. The pressure accumulator must be installed right behind the discharge

outlet of the high pressure pump. Only use one pressure accumulator (in the discharge

line) at a time in order to avoid irritation which could be caused by different pretension

levels in the accumulators.

Gas-tension in both the inlet flow stabilizer and the pressure accumulator are to be

checked regularly.

6