3

Specifications

Model GP7155A, GP7255A

Consult the factory for special requirements that must be met if the pump is to

operate beyond one or more of the limits specified above.

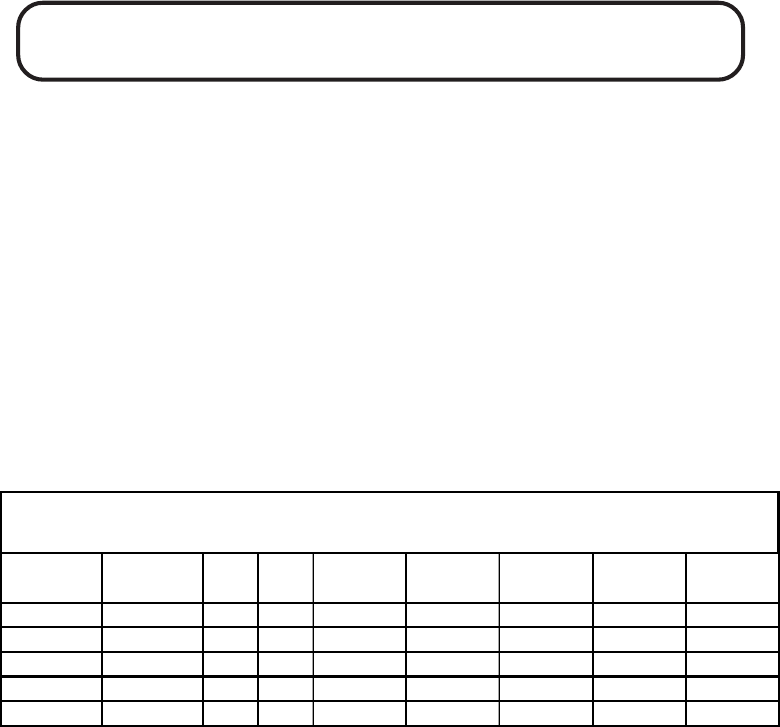

PUMP

PULLEY

MOTOR

PULLEY

RPM GPM 800 PSI 1000 PSI 1300 PSI 1500 PSI 2000 PSI

12.75 9.00

479 45.0 25.7 32.1 41.8 48.2 64.3

12.75 9.75

531 49.9 28.5 35.6 46.3 53.5 71.3

12.75 10.75

585 55.0 31.4 39.3 51.1 58.9 78.6

12.75 11.70

638 60.0 34.3 42.9 55.7 64.3 85.7

12.75 12.75

700 65.8 37.6 47.0 61.1 70.5 94.0

GP7155A, GP7255A PULLEY SELECTION & HORSEPOWER

REQUIREMENTS

PULLEY INFORMATION

Pulley selection and pump speed are based on a 1725

RPM motor and "B" section belts. When selecting

desired GPM, allow for a ±5% tolerance on pumps

output due to variations in pulleys, belts and motors

among manufacturers.

1. Select GPM required, then select appropriate

motor and pump pulley from the same line.

2. The desired pressure is achieved by selecting the

correct nozzle size that corresponds with the pump

GPM.

HORSEPOWER INFORMATION

Horsepower ratings shown are the power require-

ments for the pump. Gas engine power outputs must

be approximately twice the pump power require-

ments shown above.

We recommend that a 1.1 service factor be specified

when selecting an electric motor as the power source.

To compute specific pump horsepower requirements,

use the following formula:

(GPH X PSI) / 1450 = HP

................................................................U.S. ........................ Metric

Volume.................................................... 65.8 GPM .............. 250 LPM

Discharge Pressure ................................. 1500 PSI ................. 100 Bar

Speed ......................................................2000 PSI ................. 138 Bar

Inlet Pressure ........................................................................... Up to 700 RPM

Plunger Diameter ....................................2.17”....................... 55mm

Plunger Stroke ........................................2.05” ....................... 52mm

Crankshaft Diameter...............................1.89” ....................... 48mm

Key Width...............................................0.55” ....................... 14mm

Crankshaft Mounting............................................................... Either side

Shaft Rotation .......................................................................... Top of pulley towards manifold

Max.Temperature of Pumped Fluids ...... 140

o

F ..................... 60

o

C

Inlet Ports ................................................................................ (2) 2-1/2" NPT

Discharge Ports........................................................................ (2) 1-1/4" NPT

Weight.....................................................374 lbs. ................... 170 kg

Crankcase Oil Capacity ..........................1.6 Gal.................... 6.0 liters

Fluid End Material GP7155A.................................................. Bronze

Fluid End Material GP7255A.................................................. Nickle Plated Spheroidical Cast Iron

Mechanical Effecency @ 700 RPM ........................................ 0.83

Volumetric Effecency @ 700 RPM ......................................... 0.96