6. Turn the ON/OFF button on the machine ON.

7. As the pump starts to build pressure, begin to adjust the valves in the following

manner: start by slowly closing the concentrate valves while slowly opening the

recycle valve (Figure 2.1, Flow Control Center).

CAUTION

: Monitor machine to ensure inlet pressure of 30 - 60 psi

(2.1 - 4.1 bar) is maintained during operation.

8. After 20 - 30 minutes of flushing permeate to the drain, ensure all chemical

residue has been removed before hooking up to point of use.

While operating, the pressure range should never operate outside of the pressure

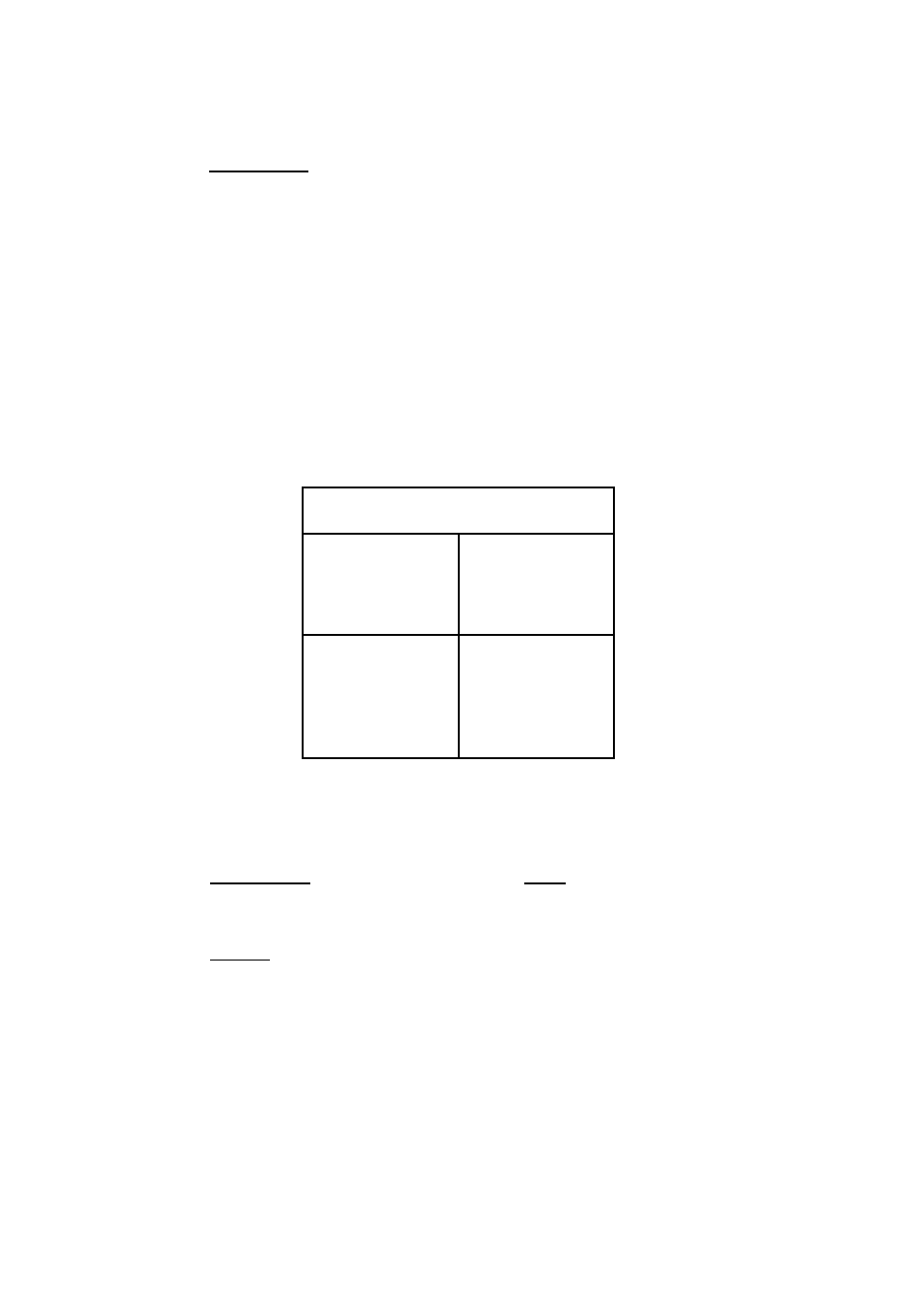

ranges displayed in Table 2.3 (E2/EZ2-Series Primary Pressure Range).

Table 2.3

E2/EZ2-Series

Primary Pressure Range*

* Primary pressure temperature for normal operation is 77°F (25°C).

CAUTION

: The E2/EZ2-Series must not operate outside the ranges listed

above.

NOTE: Optimum recovery will vary according to feed water quality.

The concentrate valve is drilled, and when completely closed the machine is run-

ning at the correct concentrate flow for a 75% recovery (Table 2.4, Flow

Specifications for E2/EZ2-Series Machines).

If the temperature of the inlet feed water is not 77°F (25°C) use the Temperature

Correction Factor Table (Technote 113). The proper adjustment of the recycle and

concentrate valves are critical to the correct operation of the machine.

5

Operating

Pressure

Operating

Range

220 psi

(15.2 bar)

165 - 250 psi

(114. - 17.2 bar)

E2/EZ2-Series