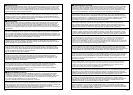

Cleaning the flow sensor:

D

F

C

E G

H

If the flow sensor is dirty, this may result in spurious error

messages (LED flashes orange).

1. Unscrew both screws

e

.

2. Remove the cover

r

.

3. Undo the screw

t

and detach the clip

z

.

4. Unscrew the cap

u

anticlockwise.

5. Remove the impeller

i

and clean it. Clean the housing of the

flow sensor.

6. Re-fit the impeller

i

with the metal part in the mounting

direction.

7. Screw the cap

u

into place clockwise.

8. Secure the cap

u

by way of the clip

z

using the screw

t

.

9. First insert the cover

r

at the top and then tighten the

two screws

e

at the bottom.

Problem Possible Cause Remedy

Pump runs, but the suction

action doesn’t take place

Pump sucks in air at a joint.

v Seal connections on suction

side so are airtight.

Leaky or damaged suction

hose.

v Check suction line for damage

and seal so is airtight.

The pump was not filled with

the liquid to be pumped.

v Fill the pump

(see “4. Operation”).

The liquid escapes over the

hose which is connected to

the delivery side during the

suction action.

1. Fill the pump again

(see “4. Operation”).

2. When starting operation hold

the pressure hose approx.

1m vertically above the

pump, until the suction

action has taken place.

Absolutely vacuum-resistant connection is achieved by using

GARDENA Suction Hoses (see point “8. Available accessories”).

Leaky screw fitting

6

at the filler

cap

7

.

v Check seal (replace if neces-

sary) and tighten connection

securely (do not use pliers).

Air cannot escape, since delivery

side is closed or remaining water

is in the pressure hose.

v Open shut-off valves

(e. g. nozzle) in the delivery

line, empty the delivery hose

or disconnect it from the

pump during priming.

The waiting time wasn’t

observed.

v Switch on the pump and wait

up to 5 min.

Suction filter or backflow prevent-

er in the suction hose clogged.

v Clean the filter or the back

flow preventer.

Too high suction height.

v Reduce suction height.

In case of any other difficulties concerning the suction action,

use GARDENA Suction Hoses with Backflow Preventer

(see point “8. Available accessories”) and fill in the liquid to

be pumped over the filler cap

7

before operation.

Problem Possible Cause Remedy

Pump motor runs,

but delivery capacity

or pressure suddenly

decreases

Suction filter at the suction

hose is sucked free.

v Reduce flow rate on the

delivery side with a control

valve, e.g. GARDENA

art. no. (2)977.

Suction filter or backflow

preventer clogged.

v Clean filter or back-flow

preventer.

Leaks at suction side.

v Eliminate leak.

Impeller blocked.

v Release impeller.

Pump motor doesn’t start

or suddenly stops

No power.

v Check fuses and electric

connections.

Circuit breaker has switched off

the motor due to overheating /

overload.

v Ensure sufficient cooling /

ventilation and clean the

impeller chamber.

Electric failure.

v Send the pump to one

of our GARDENA Service

Centres.

5000/5; 6000/6 inox:

Pump delivers and

LED flashes orange

The flow sensor is dirty.

v Clean the flow sensor.

5000/5; 6000/6 inox:

Pump switches off and

the LED shines red

No supply of fluid to be

pumped for approx. 5 minutes /

leakage on the suction side.

v Establish supply of fluid to

be pumped/check suction

line and re-start pump.

The pump ran for approx.

5 minutes against the closed

delivery side.

v Open the delivery side and

re-start pump.

For any other malfunctions please contact the GARDENA service department.

Repairs must only be carried out by GARDENA service departments or specialist

dealers authorised by GARDENA.

8. Available accessories

GARDENA Suction Hoses Kink-proof and vacuum-proof, optionally available by the metre

Art. no. 1720/1721 (19 mm (3/4")- / 25 mm (1")) without connecting

fittings or in fixed length Art. no. 1411/1418 complete with con-

necting fittings.

GARDENA Suction Hose

Fitting

For connection on the suction side. Art. no. 1723/1724

GARDENA Pump Connection

Set

For connection on the delivery side. Art. no. 1750/1752

GARDENA Suction Filter with

backflow preventer

To equip suction hoses with backflow

preventer sold by the metre.

Art. no.

1726/1727/1728

GARDENA Electronic

Manometric Switch

Automatically cuts in and out the pump

depend ingon the current operating pressure.

With dry-running safety. It must be installed

at one of the two outlets. (In the case of

Art. No. 1734 / 1736 the special mode has to

be activated for this purpose).

Art. no. 1739

18

GB

19

GB