8

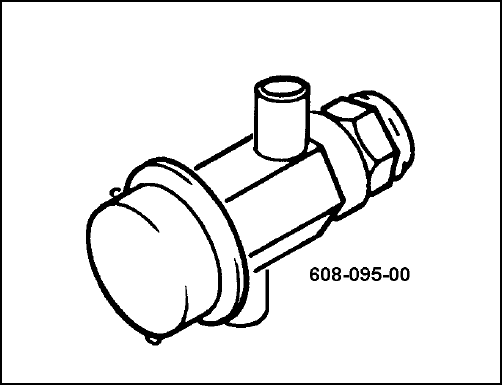

LOW AMBIENT BYPASS VALVE (Figure 9)

The HazardGard unit is designed to operate at low

outside ambient temperatures. This is accomplished by

the use of a bypass valve installed in the refrigeration

circuit. The valve is connected between the discharge

line at the compressor and the suction process tube.

The valve responds to suction pressure which, when

reduced in the system, causes the valve to open and

bypass hot gas from the high pressure side to the low

pressure side of the system. The hot gas entering the

compressor mixes with the cool gas returned through

the suction line, thus increasing the suction pressure.

The valve is preset to open when the suction pressure

reaches 50 psig. This pressure setting cannot be

altered. The system can be operated at outdoor

temperatures as low as 45°

F before the evaporator

coil will begin to accumulate frost.

To determine if the valve operates, block the return air

to the evaporator coil. Turn on the unit and touch the

tube at the bypass valve outlet which connects to the

suction process tube. When the low side pressure

reaches approximately 50 psig, the valve will begin

to open and the tube will get hot. This method will

determine if the valve is responding to the suction

pressure change.

FIGURE 9

LOW AMBIENT Bypass

VALVE

EQUIPMENT REQUIRED:

1. Voltmeter

2. Ammeter

3. Ohmmeter

4. E.P.A Approved Refrigerant Recovery System

5. Vacuum Pump (capable of 200 microns or less

vacuum).

6. Acetylene Welder

7. Electronic Halogen Leak Detector (G.E. Type

H-6 or equivalent).

8. Accurate refrigerant charge measuring device

such as:

a. Balance Scales - 1/2 oz. accuracy

b. Charging Board - 1/2 oz. accuracy

9. High Pressure Gauge - (0-400 lbs.)

10. Low Pressure Gauge - (30" - 150 lbs.)

11. Vacuum Gauge - (0-1000 microns)

EQUIPMENT MUST BE CAPABLE OF:

1. Recovering CFC’s as low as 5%.

2. Evacuation from both the high side and low side

of the system simultaneously.

3. Introducing refrigerant charge into the high side of

the system.

4. Accurately weighing the refrigerant charge actually

introduced into the system.

5. Facilities for flowing nitrogen through the

refrigeration tubing during all brazing processes.

SEALED REFRIGERATION SYSTEM

REPAIRS