6

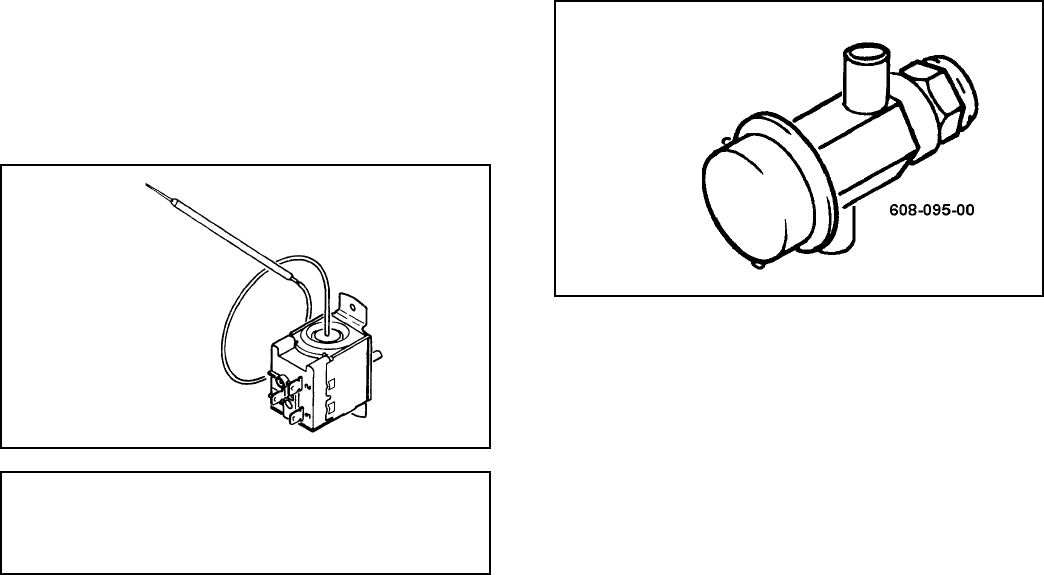

THERMOSTAT

A cross ambient thermostat is used to maintain the desired

comfort level. The thermostat reacts only to a change in

temperature at the bulb location. Important to the successful

operation of the unit is the position of the sensing bulb in relation

to the evaporator (see Figure 8).

TEST

Remove the wires from the thermostat. Turn the thermostat to

its coldest position. Check to see if there is continuity between

the two terminals. Turn the thermostat to its warmest position.

Check continuity to see if the thermostat contacts open.

Note: The temperature must be within the range listed to check

the thermostat. Refer to the troubleshooting section in this

manual for additional information on thermostat testing.

LOW AMBIENT BYPASS VALVE (Figure 9)

The HazardGard unit is designed to operate at low outside

ambient temperatures. This is accomplished by the use of a

bypass valve installed in the refrigeration circuit. The valve

is connected between the discharge line at the compressor

and the suction process tube. The valve responds to suction

pressure which, when reduced in the system, causes the

valve to open and bypass hot gas from the high pressure side

to the low pressure side of the system. The hot gas entering

the compressor mixes with the cool gas returned through the

suction line, thus increasing the suction pressure. The valve

is preset to open when the suction pressure reaches 50 psig.

This pressure setting cannot be altered. The system can be

operated at outdoor temperatures as low as 45°

F before the

evaporator coil will begin to accumulate frost.

To determine if the valve operates, block the return air to the

evaporator coil. Turn on the unit and touch the tube at the

bypass valve outlet which connects to the suction process

tube. When the low side pressure reaches approximately 50

psig, the valve will begin to open and the tube will get hot. This

method will determine if the valve is responding to the suction

pressure change.

FIGURE 9

LOW AMBIENT

Bypass VALVE

SEALED REFRIGERATION SYSTEM

REPAIRS

Equipment Required:

1. Voltmeter

2. Ammeter

3. Ohmmeter

4. E.P.A Approved Refrigerant Recovery System

5. Vacuum Pump (capable of 200 microns or less vacuum).

6. Acetylene Welder

7. Electronic Halogen Leak Detector (G.E. Type

H-6 or equivalent).

8. Accurate refrigerant charge measuring device

such as:

a. Balance Scales - 1/2 oz. accuracy

b. Charging Board - 1/2 oz. accuracy

9. High Pressure Gauge - (0-400 lbs.)

10. Low Pressure Gauge - (30" - 150 lbs.)

11. Vacuum Gauge - (0-1000 microns)

Equipment Must Be Capable of:

1. Recovering CFC’s as low as 5%.

2. Evacuation from both the high side and low side of the

system simultaneously.

3. Introducing refrigerant charge into the high side of the

system.

4. Accurately weighing the refrigerant charge actually intro-

duced into the system.

5. Facilities for fl owing nitrogen through the refrigeration

tubing during all brazing processes.

RANGE: Thermostat

(Part No. 618-225-02)

60° F ( ± 2° ) to 90° F( ± 4° )

FIGURE 8

SENSING

BULB LOCATION