7

www.retroaire.com

The Right Fit For Comfort

RC11 PERFORMANCE DATA*

UNIT SIZE COOLING BTUH EER FRESH AIR CFM

9 9500 10 40/35

12 11,900 10 40/35

15 14,700 9.2 40/35

18 16,900 9.1 40/35

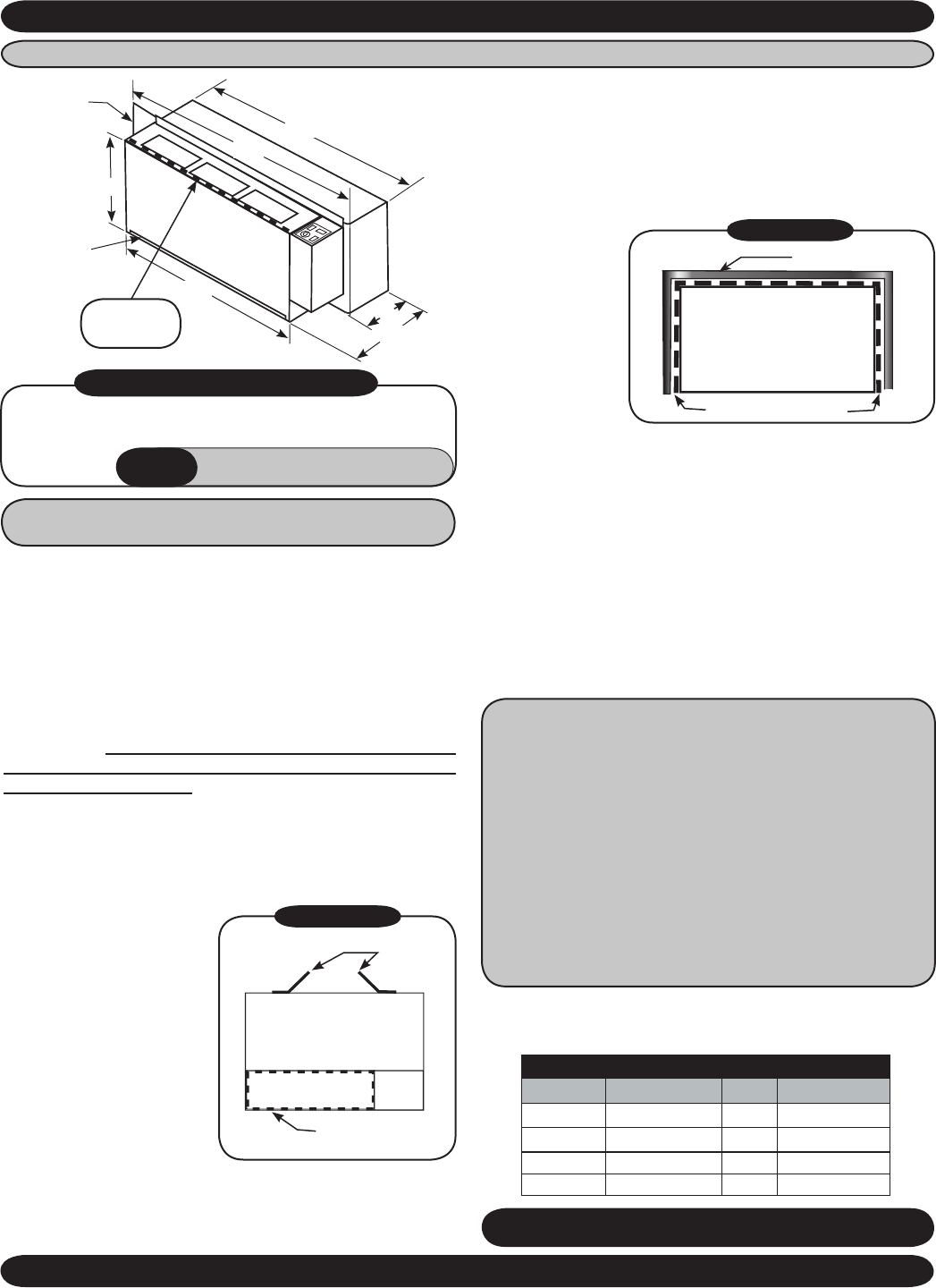

1. Take unit out of packaging.

2. Slide unit into wall sleeve. The supply duct on the cool-

ing chassis should line up with the supply vent on the

room cabinet. The weather angles should require no

adjustment.

3. Slide unit out of wallsleeve.

IMPORTANT: The correct condenser air baffl es must be

installed or performances may be impaired and/or the

war

ranty will be voided.

4. Baffl e Installation - Remove baffl es from kit bag sup-

plied with unit. Install left and right side baffl es on the

condenser coil in existing holes:

• Choose the proper fi tting baffl es for your applica-

6. Apply 2” x 1 1/2” open cell foam strips around supply air

duct to ensure that all the conditioned air is delivered

into the room. Failure to do so results in recirculation of

the conditioned air around the wall sleeve and through

the unit causing the unit to short cycle, thus raising

operating costs through improper heating and cooling

(Figure A2).

*Refer to the charts on page 23 for electrical and

optional electric heat specifi cations.

Two sets of baffl es are provided in your kit to accommodate

varying wall sleeve depth.

INSTALLATION INSTRUCTIONS

RC11 REPLACEMENT PTAC

• 1 Installation Manual

• 1 Top Baffl e

• 2 Sets of Lt.&Rt. Baffl es

• Screws

• 1/2” x 1/2” Open Cell Foam Tape

• 1” x 1” Open Cell Foam Tape

• 2” x 1 1/2” Open Cell Foam Tape

• 1 ea. 2-Position

Connector & Pin Mate

• 14AWG Yellow Wire

HYDRONIC

ONLY

RC11 BAFFLE INSTALLATION KIT

Figure B2

Removable

Weather Seals

Air Filter

Install

1/2” x 1/2”

Foam Tape

18

7/8

”

11

1/4

”

34

1/2

”

39

3/4

”

30

1/4

”

14

1/8

”

tion.

• Baffles must come

in contact with the

outdoor louver.

• Make sure baffles

are directed inward

toward the center of

coil.

• Secure baffl es tightly

to the condenser coil

using the screws pro-

vided.

5. Apply one piece of 1/2” x 1/2” open cell polyfoam to top

fl ange of evaporator block off (

See illustration: top of

this page).

Figure A2

2” X 1 1/2” Supply Air

Duct Foam Tape

Baffl es-Directed Inward

Toward Coil

7. 1” x 1” Open

cell foam strips

are provided to

prevent outside

air from enter-

ing around the

chassis to the

room from the

sides and top

of the cabinet. Install between wall sleeve and cooling

chassis. It is imperative to have a solid air seal between

wall sleeve and chassis. Failure to do so will result in

air leakage from outdoor to indoor causing system

problems i.e. Coils freezing, short cycling, and constant

running of unit. If installer is in need of more foam than

supplied in kit, consult factory (

Figure B2).

8. Once confi dent that all seals are the correct size and in

the proper location, and the correct baffl es are attached

to the condenser coil in the proper orientation, slide

unit into fi nal position and tighten any tie down bolts or

screws as necessary.

Hydronic Only: Remove the 2-position connector as-

sembly from kit bag supplied with unit (this will have 2

yellow wires attached). Connect this 2-position connector

to the 2-position connection located on the bottom of the

control box panel.

To

Connect Aquastat:

A. Remove the black jumper wire located on the bot-

tom panel of the control box (this is also terminated

with a 2-position connector).

B. Cut the jumper wire in the middle and splice the

aquastat to the jumper.

C. Place the connecter back into original location.

Refer to wire diagram on the unit for details.

9. Connect line cord.

10. See Final Inspection and Startup on page 20.

Front View

Cooling Chassis

Wall Sleeve

1x1 Foam Tape