IMPORTANT POINTS ON SERVICE OPERATING SAFETY

Please follow these instructions carefully :

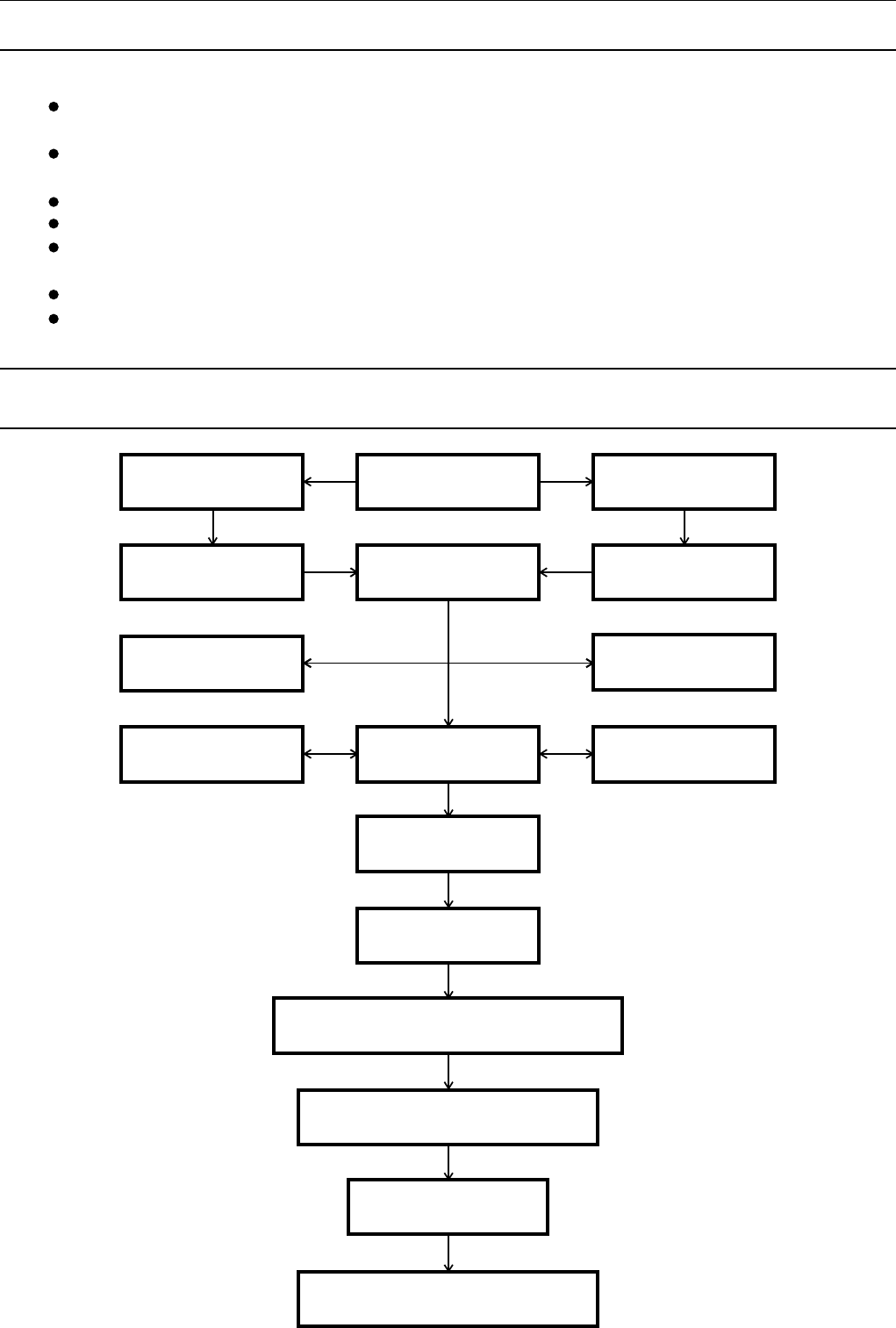

FLOW CHART FOR INSPECTING AND REPAIRING THE UNIT

- 1 -

Unplug the unit to avoid any danger from electric shock before disassembling the unit for

repair.

If there is any sound of the refrigerant circulating when in operation, avoid touching the

cooling coils.

If you need to perform any welding or soldering, be sure you are in a well ventilated area.

Only a qualified professional should perform any welding on the unit.

When repairing the unit, the specifications listed in this manual must be strictly adhered

to when replacing any components.

When replacing any electrical components they should be factory approved units.

Be sure that any electrical components are properly wired and in place.

Electricity shutdown

Dehumidifier

doesn't work

Check if drain bucket

water level switch

is broken

Check fuses on

main switch

Can not dehumidify

Humidity sensor

is broken

Humidity setting on

continuous operation

Over load protector is

faulty

Check if air filter is

clogged

Capacitors are faulty

Compressor doesn't

work

Refrigerant is leaking

Maintain

&

repair system

Supply Nitrogen 15Kg/cm² from low

pressure side and locate the leakage

Use oxygen acetylene and 5% silver

iron to fill cracks and holes

Pump vacuum for at

least 15 minutes

After filling with

refrigerant proceed to test run